全站搜索

Pesquisar em todo o sítio Web

Pesquisar em todo o sítio Web

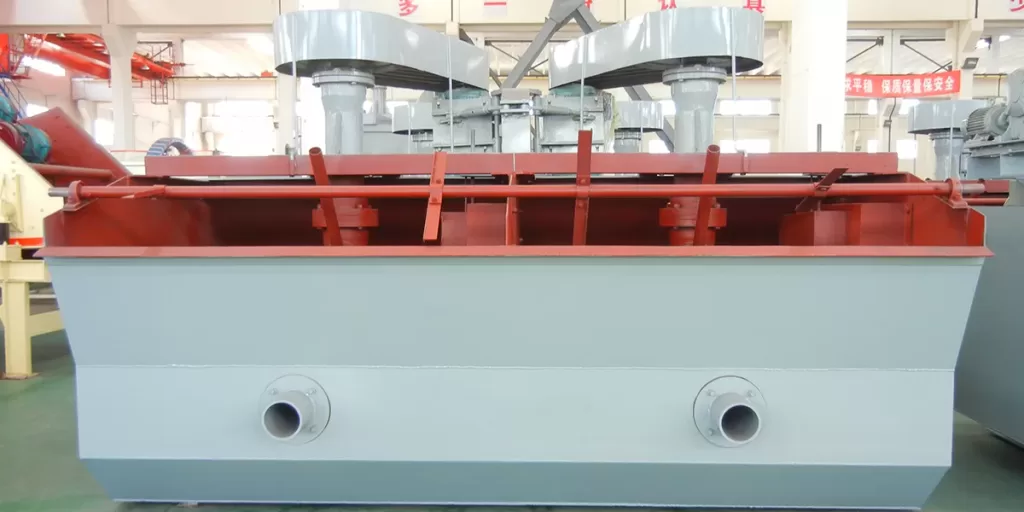

Our Flotation Machine are available in different styles and numerous model sizes in each style to adapt to various mineral separation requirements.

A flotation machine is a device that utilizes chemical differences in mineral surfaces to separate valuable minerals from waste. Its key roles are to concentrate low grade ore into a high grade concentrate, to separate a wide range of valuable minerals, and to remove impurities.

Flotation is essential in mineral processing for base metals (copper, lead, zinc, nickel), precious metals (gold, silver, platinum), iron ore upgrading, industrial minerals (phosphate, potash, fluorspar), coal cleaning, and even wastewater treatment.

Flotation works by selectively altering mineral surfaces with chemicals (reagents) to make target minerals water-repellent (hydrophobic). These hydrophobic minerals attach to air bubbles introduced into the pulp and float to the surface for collection.

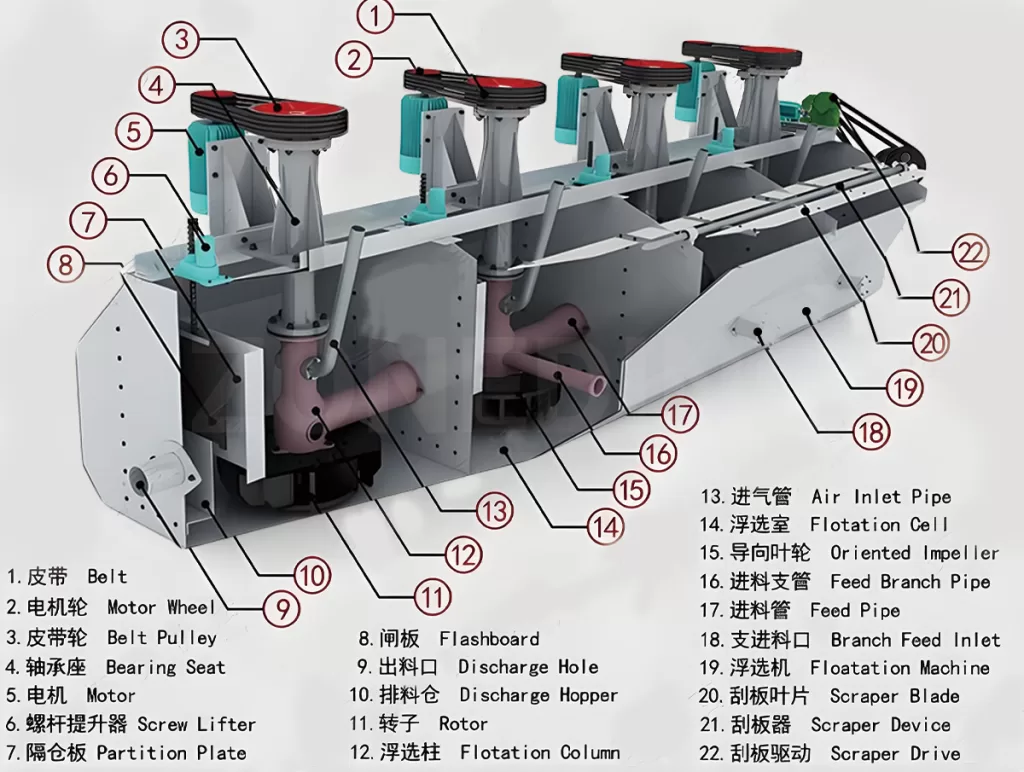

There are three main types of ZONEDING flotation equipment, namely mechanical agitation flotation machines (BF, JJF type), inflatable agitation flotation machines (XCF type, KYF type) and inflatable flotation machines (XJB rod flotation machine).

| Category | Specification Modelo | Effective cubage (m³) | Processing capacity (m³/min) | Main shaft loam board | Dimensions (L×W×H) (m) | Single trough Weight (t) | |||

| Power(kw) | Rotate Speed(r/min) | Rotate Speed(r/min) | Power(kw) | ||||||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7×0.7×0.7 | 0.5 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3.0 | 400 | 25 | 1.1 | 0.90×0.82×0.85 | 1.0 | |

| XJK-1.1 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1 | 1.4 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75×1.6×1.1 | 2.5 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2×2.2×1.2 | 3.6 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7×0.7×0.75 | 0.5 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9×0.82×0.95 | 1.0 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1.1 | 1.9 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75×1.6×1.15 | 2.6 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85×2.05×1.2 | 2.9 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.4 | 4.2 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.7 | 4.5 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85×3.8×2 | 9.9 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4×1.4×1.1 | 1.7 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6×2.15×1.25 | 2.4 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.4 | 4.5 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.7 | 4.9 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85×3.8×1.7 | 8.0 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9×3.8×2.0 | 10.5 | |

Mechanical: Relies on an impeller for air suction and slurry circulation; classic design, good for coarser particles, stable operation, but relatively higher energy consumption. Inflatable (e.g., self-aerating, jet, flotation columns): Often requires external blowers for air supply; allows large, adjustable airflow, lower energy consumption, high efficiency for fine particles, easier to scale up. Selection depends on ore characteristics (particle size, density), capacity, separation stage (roughing/cleaning), energy consumption, and investment budget.

Aeration rate: Directly affects bubble quantity, size, and dispersion, influencing mineral-bubble collision probability and froth stability. Insufficient air lowers recovery; excessive air can disrupt the froth layer or increase gangue entrainment. Usually controlled by adjusting the air inlet valve or blower frequency. Pulp level: Determines the froth depth and the height of the separation zone. High level gives stable froth but risks gangue entrainment (lower grade); low level results in a thin, brittle froth, potentially losing valuable minerals (lower recovery). Typically adjusted via the weir height in the tailing box or automated control systems.

Causes: Severe wear of impeller/stator, insufficient impeller speed, excessively high pulp density, too coarse feed particle size, improper clearance between impeller and cell bottom, or large fluctuations in feed rate. Solutions: Inspect and replace worn parts (impeller/stator), ensure correct speed, adjust pulp density appropriately, control grinding fineness, adjust impeller clearance, stabilize feed rate.

Other key components include: Main bearings (need regular lubrication, temperature/noise checks), drive system (belt tension/wear, reducer oil level/quality), tank body (check for corrosion, wear, leaks), froth scraping mechanism (scraper wear, drive function), and level control system (sensor accuracy, actuator flexibility).