全站搜索

Buscar en todo el sitio web

Buscar en todo el sitio web

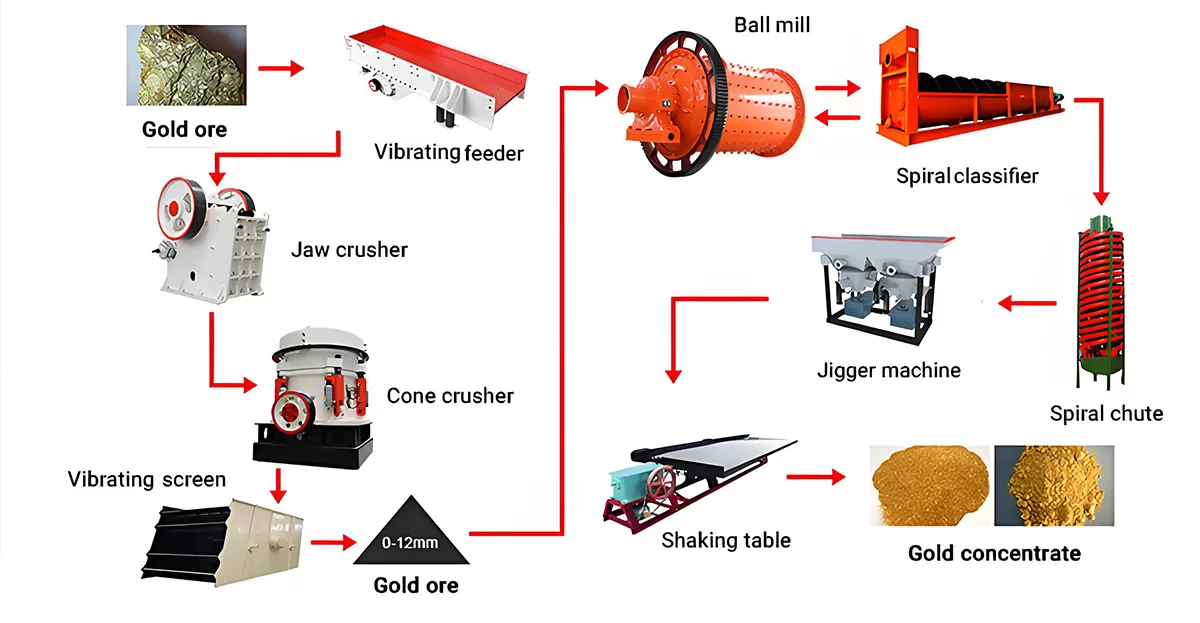

From gold to tungsten, our Jigging Separator Machine handle it all – versatile solutions for every mining need

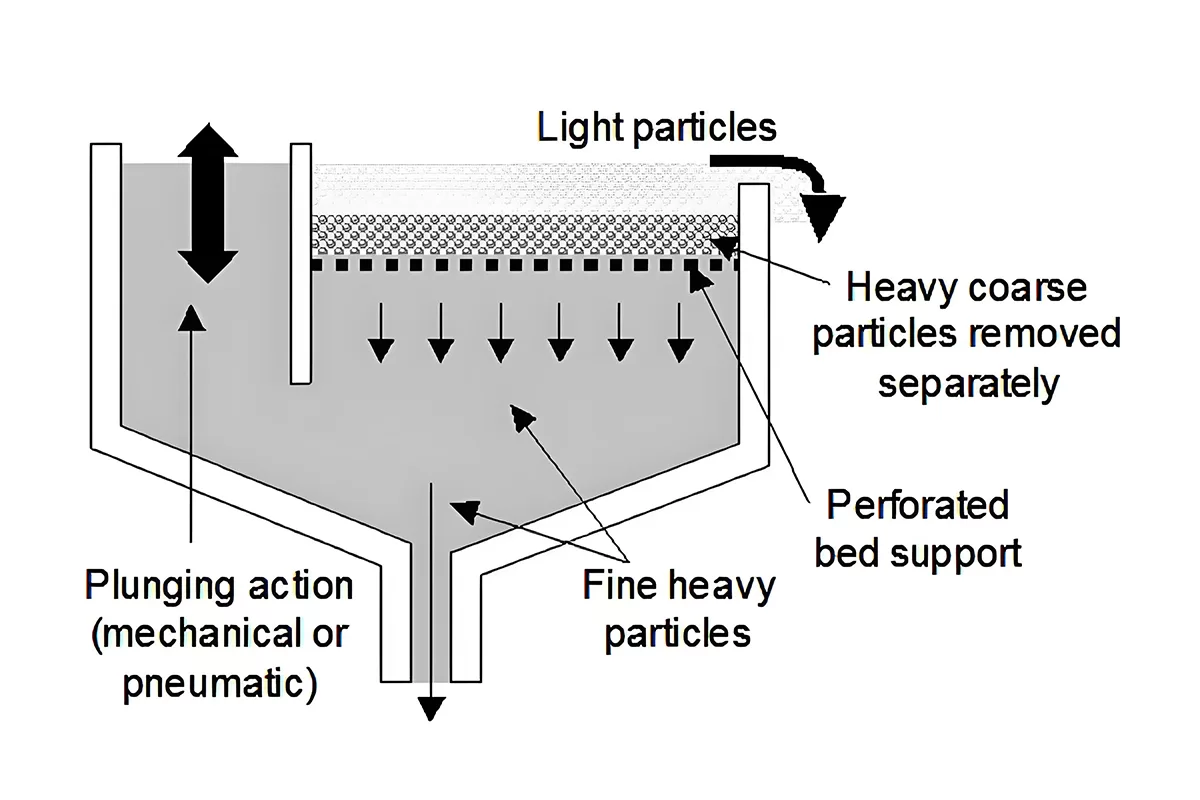

A jigging machine is a piece of equipment that implements the jigging process. The process in which the material is sorted according to density differences, mainly in a vertically rising and falling stream of variable speed media. The difference in size and shape of the material has an effect on the result of the separation. The medium used in jigging can be either water or air. When water is used as the sorting medium, it is called hydraulic jigging; when air is used as the sorting medium, it is called wind jigging.

According to the different equipment structure and water flow movement, it can be roughly divided into the following categories: piston jigger, diaphragm jigger, air pulsation jigger, and dynamic screen jigger.

Selection Guide

Jig machine selection steps: first and jig machine manufacturer telephone contact, by asking some technical questions, you can roughly understand whether this manufacturer is professional, the next step is to carry out beneficiation tests, this step is critical, you bring ore to the jig machine manufacturer, the general situation is 30-40 kg of raw ore, the regular manufacturers have small jig machine available for free test, the test is not as good as the actual production indicators, but also The test is not as good as the actual production indicators, but also from the side to grasp the ore beneficiation indicators, and jigger manufacturer’s technology is perfect, if the test link can reach the ideal indicators, then this manufacturer has a certain strength, and then is to order equipment links, look at the quality of jigger equipment, external viewing jigger working principle is reasonable, and according to your site conditions for improvement, of course, the important issue is the price, the price is also based on the above The price is also based on the above cases of negotiation, the final order products, jigger manufacturers have professional technical staff to install and commission until you produce qualified products.

Jig concentrator is a gravity separator machine used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc

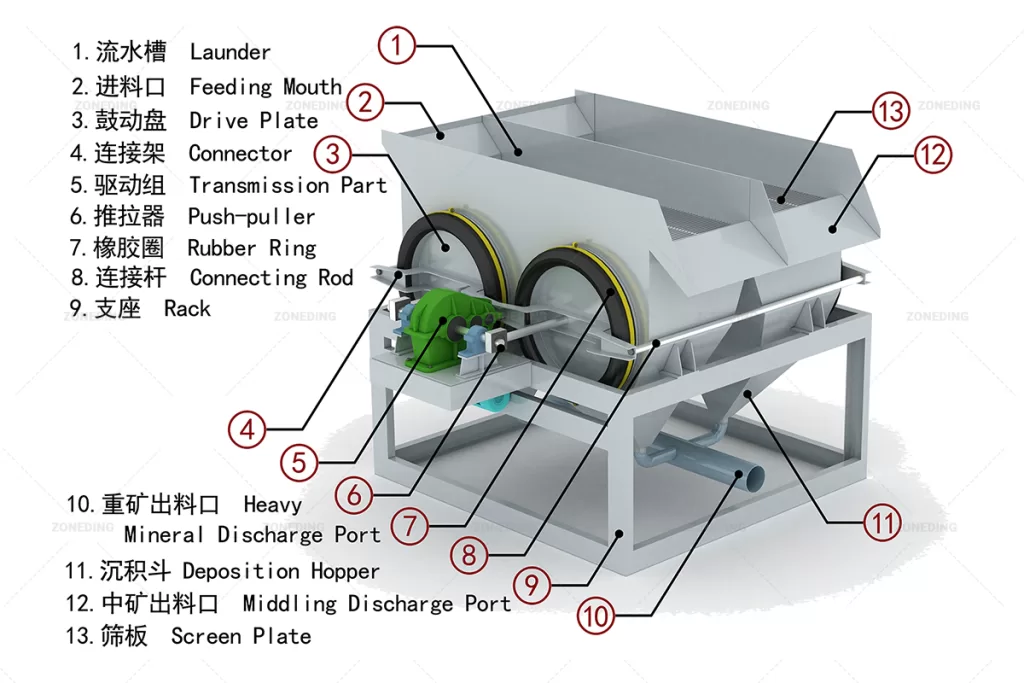

Raw ore is sent into the jigging chamber, due to the drumming effect of the diaphragm, the mineral grains in the media are stratified according to the specific gravity, fine and heavy mineral grains through the artificial bed particles of the gap and sieve holes, deposited in the jigging hopper of the hopper storage hopper, the upper layer of coarse and light mineral grains (materials) by the media flow rushed to the sieve at the end of the discharge port, due to the after jigging chamber than the former jigging chamber location is lower than the 50mm, so the light mineral grains through the front chamber tailboard overflow into the back room, and again subject to jigging, after which the different minerals are separated. After that, the minerals with different specific gravity will be separated and the sorting operation will be completed.

Adopting conical slide valve, the failure rate is reduced by 80%, energy consumption is small, it can realize the sorting needs of different materials and increase the processing capacity by more than 35%.

1. Energy saving, high efficiency, environmental protection.

2. Wide range of particle size, 0-30mm particle size minerals can be classified into the selection.

3. The base is made of channel steel, and the collective is made of welded steel plate with good quality and high abrasion resistance.

4. The classifier adopts tile lining, with very low maintenance rate and higher durability of wearing parts.

| Modelo | Jig Area (M2) | Stroke (R/Min) | Feeding size (mm) | Hutch Water ( T/H) | Pressure Water (kg/cm2) | Capacity;(T/H) | Power;(KW) | Overall dimensions (mm) | Weight (T) |

| JT0.57-1 | 0.57 | 60-160 | <6 | 1-2 | ≥0.3 | 1-2.5 | 1.5 | 1560x820x1550 | 0.612 |

| JT1-1 | 1.04 | 60-160 | <10 | 2-3 | ≥0.3 | 4-10 | 2.2 | 1322x1190x1915 | 0.9 |

| JT2-2 | 2.28 | 60-160 | <10 | 2-4 | ≥0.3 | 8-15 | 3 | 3225x1550x2150 | 1.637 |

| JT4-2 | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 7.5 | 4240x1990x2750 | 4.6 |

| JT4-2A | 4 | 50-125 | <10 | 4-8 | ≥0.1 | 8-16 | 8 | 4240x1990x2750 | 4.6 |

| JT5-2 | 4.86 | 80-120 | <10 | 4-10 | ≥0.1 | 10-20 | 7.5 | 3940x2006x2580 | 4.6 |

Contesta: Los factores clave que influyen en la separación son el movimiento de la mesa (carrera y frecuencia), el volumen y la pendiente del agua, la velocidad y la concentración de la alimentación y el tamaño y la forma de las partículas del material alimentado. El ajuste adecuado de estos factores es fundamental para una separación eficaz. Las pendientes longitudinal y transversal de la mesa deben controlarse con precisión. La concentración de la alimentación también debe ser la adecuada, normalmente 20-30% para minerales gruesos y 15-25% para minerales finos.

Contesta: El funcionamiento implica observar la superficie de la mesa y ajustar la pendiente, el caudal de agua y la velocidad de avance. El mantenimiento regular incluye la comprobación de piezas sueltas, la lubricación de los componentes móviles, la inspección del desgaste y la limpieza de la superficie de la mesa. El mantenimiento preventivo debe realizarse con regularidad, con intervalos que oscilan entre cada mes y una vez al año.

Contesta: Los problemas más comunes pueden incluir sacudidas de la mesa o cortes entrecortados, distribución desigual del material o separación deficiente. La solución de problemas puede incluir la comprobación de pernos sueltos, muelles dañados o desalineación, el ajuste de la tensión de la correa, la inspección de los componentes eléctricos y la lubricación adecuada. Si hay ruidos extraños, identifique la fuente y elimine el problema.

Contesta:

Ventajas: Las mesas de agitación ofrecen altos índices de enriquecimiento, son relativamente sencillas de manejar y producen zonas de separación visibles, lo que permite ajustarlas y controlarlas fácilmente. Son adecuadas para una amplia gama de tamaños y densidades de partículas.

Desventajas: Suelen tener menor capacidad de producción que otros métodos, como las plantillas o las espirales. También requieren un espacio relativamente grande y consumen una cantidad significativa de agua.

Contesta: La selección depende del material que se procese, del caudal deseado y de la gama de tamaños de las partículas. Los factores a tener en cuenta son la superficie de la plataforma, la longitud de la carrera y el diseño de la canaleta. Se recomienda consultar a un fabricante o experto para determinar la configuración óptima.