全站搜索

Buscar en todo el sitio web

Buscar en todo el sitio web

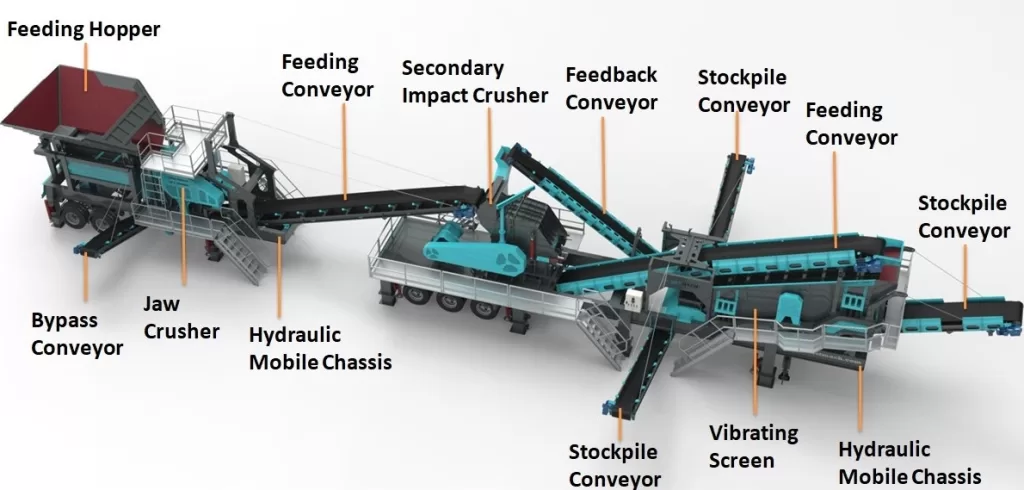

This machine mainly consists of hopper, vibrating feeder, primary crushing equipment, conveyer belt, multilayer screen, medium crushing equipment, fine crushing equipment, movable belt conveyor, sand washer & washing apparatus and electric controlling equipment.

High transport costs and long setup times hurt your bottom line. Mobile impact crushers offer a flexible, powerful solution right where you need it.

Mobile impact crushers provide unmatched site flexibility, rapid setup, lower transport costs for materials, and the ability to process specific materials effectively on location, unlike stationary units.

This mobility transforms how projects are planned and executed. Stationary plants are permanent, requiring materials to be brought to them. Mobile plants go to the materials, offering significant operational advantages.

Mobile impact crushers directly solve these problems, offering speed and flexibility stationary units cannot match.

Mobile impact crushers eliminate lengthy site prep, reduce material hauling costs drastically, deploy rapidly, and move easily with the job. These advantages boost efficiency for many projects.

These benefits translate directly into cost savings and increased productivity. Unlike fixed plants, mobile crushers require minimal site preparation. This reduces initial investment and speeds up project timelines. Let’s explore the specific advantages in detail.

Mobile impact crushers excel in these fields, offering unmatched performance and flexibility.

Mobile impact crushers are ideal for construction and demolition recycling, quarrying operations requiring frequent relocation, road construction projects needing on-site material processing, and mining operations in remote areas.

Mobile impact crushers effectively process concrete, asphalt, limestone, and softer ores. However, they are less suited for extremely hard or abrasive materials like granite or some types of iron ore.

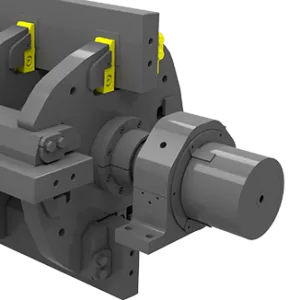

When selecting a mobile impact crusher, the most important parameters are crusher capacity (tons per hour), feed size, desired output size, material hardness, and the unit’s mobility features (tracked or wheeled).

| Modelo | ZDM938F1210 | ZDM938FW1214 | ZDM1149F1315 | ZDM1349HD1110 | ZDM1349HD1315 |

| Longitud del transporte(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Anchura del transporte(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Altura de transporte(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Longitud máxima(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Anchura máxima(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Altura máxima(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Peso(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

A systematic approach based on your specific needs will lead you to the perfect fit.

To determine the right mobile impact crusher model, start by calculating your required hourly throughput, then define the desired output particle size distribution, and finally consider the material’s hardness and abrasiveness.

Understanding the main operating costs of a mobile impact crusher is essential for profitability.

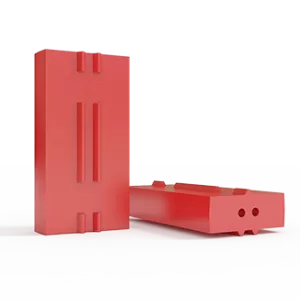

The primary operating costs for mobile impact crushers are fuel consumption, wear part replacement (especially impact hammers and liners), routine maintenance, and labor costs.

Following key operational and maintenance practices is essential for mobile impact crushers.

Daily operation and maintenance should include pre-start inspections, proper feeding techniques, monitoring crusher performance, and regular cleaning to prevent buildup and ensure optimal operation.

Understanding the strengths of each type will help you make the best choice.

Choose a mobile impact crusher for softer to medium-hard materials, where a cubical product shape is desired. Opt for a mobile jaw crusher for hard, abrasive materials requiring primary crushing, or a mobile cone crusher for finer crushing stages.

La selección depende de las características del material (tamaño máximo de alimentación, dureza, abrasividad), el rendimiento requerido (tph), el tamaño de salida deseado (CSS), la potencia del motor disponible y el presupuesto. Un análisis minucioso garantiza un rendimiento óptimo y rentable.

Una instalación correcta requiere una base sólida y nivelada y una alineación precisa. Un funcionamiento correcto implica comprobaciones previas minuciosas, una puesta en marcha en vacío, una alimentación uniforme controlada, evitar la sobrecarga/ahogo y seguir la secuencia de parada adecuada.

Las comprobaciones diarias incluyen la fijación, la lubricación y la inspección visual de las piezas de desgaste. El mantenimiento regular implica inspecciones más profundas y la revisión de los componentes. Prolongue considerablemente la vida útil de las placas de las mandíbulas mediante una selección adecuada del material, una alimentación uniforme, un cribado previo y una rotación o volteo estratégicos de las placas.

Entre las averías más comunes se encuentran las paradas repentinas (ahogamiento), la reducción del rendimiento, los problemas con las placas de mordazas, el sobrecalentamiento de los cojinetes, las vibraciones excesivas y la rotura de las placas basculantes. La localización de averías implica identificar sistemáticamente causas como bloqueos, desgaste, piezas sueltas o ajustes incorrectos.

Las trituradoras de mandíbulas destacan en la trituración primaria de materiales grandes y duros gracias a su robustez. Trituradoras de cono son más adecuadas para la trituración secundaria/terciaria de roca dura, ya que ofrecen una mayor reducción y una mejor forma. Trituradoras de impacto producen un excelente producto cúbico pero se desgastan mucho más rápido en roca dura y abrasiva.