全站搜索

Effectuer une recherche sur l'ensemble du site web

Effectuer une recherche sur l'ensemble du site web

This machine mainly consists of hopper, vibrating feeder, primary crushing equipment, conveyer belt, multilayer screen, medium crushing equipment, fine crushing equipment, movable belt conveyor, sand washer & washing apparatus and electric controlling equipment.

A mobile jaw crusher is a crushing unit integrating a jaw crusher, feeder, conveyor, and other components onto a movable chassis. Its key advantages include high flexibility, convenient relocation, reduced material transport costs, and rapid deployment.

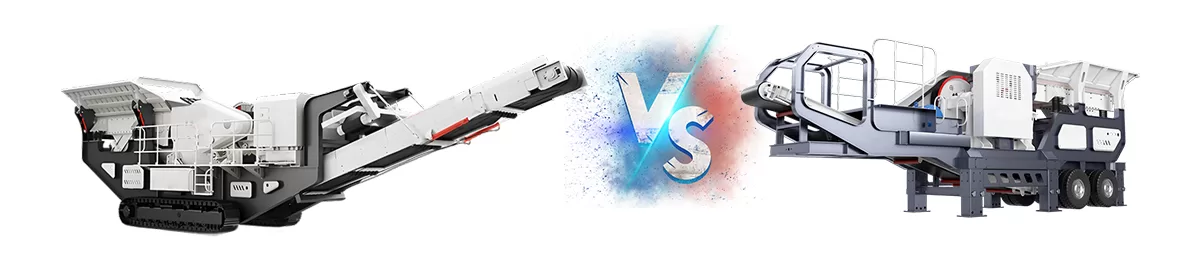

Choosing between tracked and wheeled mobile jaw crushers depends on your project’s specific requirements.

Tracked mobile jaw crushers excel in harsh terrains, offer zero-radius turning, and don’t need special towing. They are ideal for mines, large quarries, and uneven sites. Wheeled mobile jaw crushers offer easy highway transport, fast movement speeds, and require a truck for towing, fitting construction waste disposal, urban infrastructure, and quarries with paved roads.

Both types have their own advantages. The choice depends on the mobility requirements and site conditions.

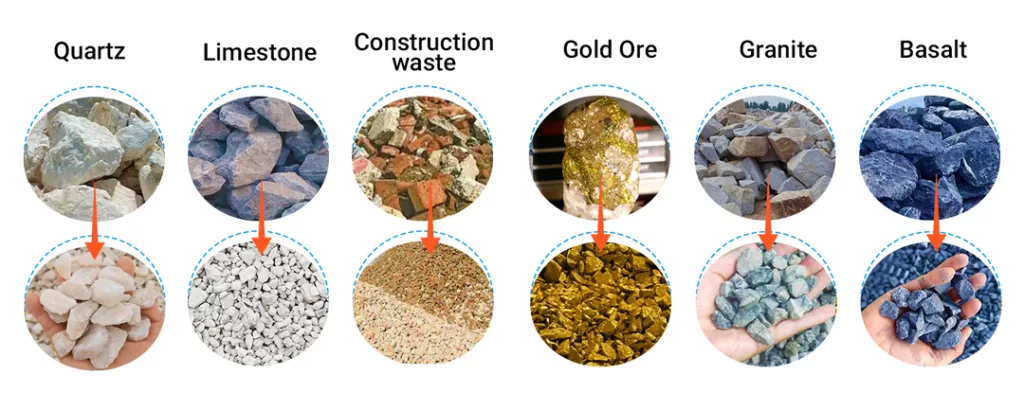

Mobile jaw crushers primarily handle materials with medium to high hardness, including various ores, rocks, and construction waste. For reinforced concrete or large materials, proper feeding and pre-screening are essential.

To select the right mobile jaw crusher model, understand key parameters such as processing capacity (tons per hour), maximum feed size, and discharge port adjustment range. Accurately estimate the processing capacity required for your project.

| Modèle | ZDM938HD80 | ZDM1149HD98 | ZDM1349HD110 | ZDM1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Concasseur à mâchoires | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacité (t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Core components of a mobile jaw crusher include a high-performance jaw crusher, a powerful feeding system with pre-screening, a reliable power system (diesel engine/motor), and an intelligent control system for ease of use and diagnostics.

Proper maintenance and operation are key to minimizing downtime and maximizing efficiency.

Key maintenance points include regular lubrication, tightening of bolts, cleaning, and timely replacement of worn parts. Operating costs can be reduced through proper operation and preventative maintenance.

Daily Checks: Perform regular checks of lubrication levels, bolt tightness, and overall cleanliness.

Choosing ZONEDING is crucial for your long-term success.

ZONEDING’s mobile jaw crusher features hybrid or fully electric power, high levels of automation and intelligence, better dust and noise control, as well as a lighter, more robust design.

Selection hinges on material characteristics (max feed size, hardness, abrasiveness), required throughput (tph), desired output size (CSS), available motor power, and budget. Careful analysis ensures optimal, cost-effective performance.

Proper installation requires a robust, level foundation and precise alignment. Correct operation involves thorough pre-checks, empty start-up, controlled uniform feeding, avoiding overload/choking, and following the proper shutdown sequence.

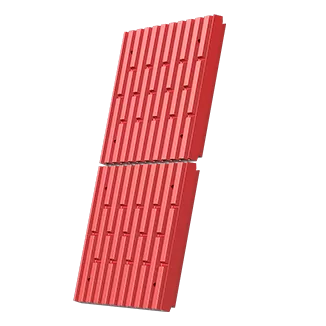

Daily checks include fasteners, lubrication, and visual inspection of wear parts. Regular maintenance involves deeper inspections and component servicing. Extend jaw plate life significantly through proper material selection, uniform feeding, pre-screening, and strategically rotating or flipping the plates.

Common faults include sudden stops (choking), reduced output, jaw plate issues, bearing overheating, excessive vibration, and toggle plate breakage. Troubleshooting involves systematically identifying causes like blockages, wear, loose parts, or improper settings.

Jaw crushers excel at primary crushing of large, hard materials due to their robustness. Cone crushers are better suited for secondary/tertiary hard rock crushing, offering higher reduction and better shape. Impact crushers produce excellent cubical product but wear much faster on hard, abrasive rock.