全站搜索

Effectuer une recherche sur l'ensemble du site web

Effectuer une recherche sur l'ensemble du site web

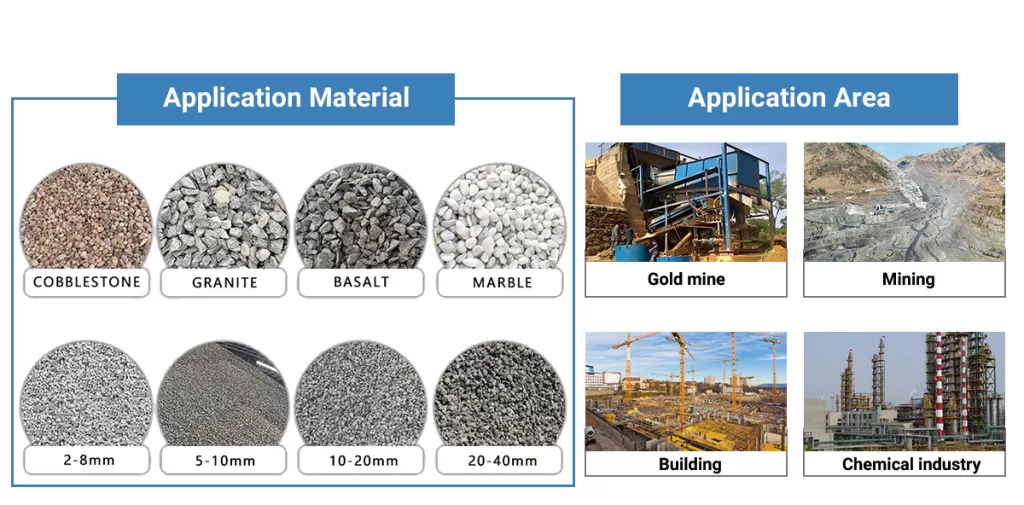

The Mud And Stone Separator like stones, waste, coal, and wet/sticky substances based on size, shape, and proportion, easing downstream load. It offers adjustable screening size and auto-adjusting speed, supporting resource conservation and recycling.

Debris separator, also known as separating screen, roller screen, butterfly screen, etc. Due to the large mud content of the stone excavated from some sand and stone yards, the use of the stone will cause problems such as crusher blockage, low production capacity, poor sand and stone quality, and the labor cost is too high and the efficiency is low. The mud rock separator produced by our company can not only solve the shortage of sand and stone resources, but also can be quickly separated without water. It can not only replace the traditional feeder and shale shaker, but also open up new vitality for the sand industry.

It is applicable to the separation conditions of various stones such as mud rock/sand stone/ore, various domestic wastes, various commercial/industrial wastes, coal, decoration/construction wastes, viscous wet materials, etc.

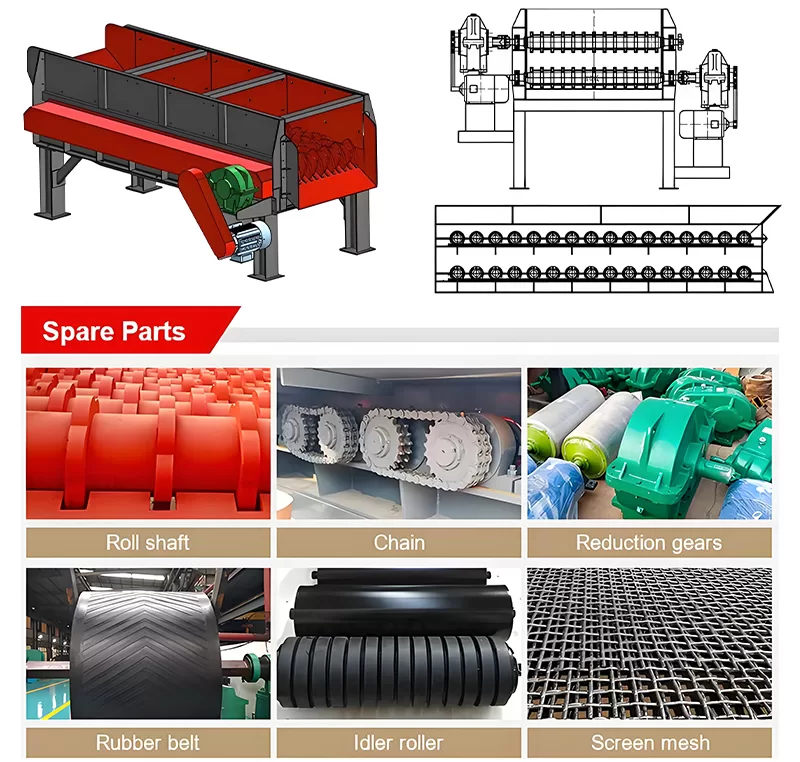

It is mainly composed of a box, a lining plate, a disc, a transmission shaft, a speed regulating motor, a chain sprocket, and other structures.The material is put into the sieve box from the feeding port. The sprocket drives the roller to turn over, and the material is driven forward by the roller. The soil leaks out from the gap, and falls onto the belt conveyor to be discharged. The bulk material above the roller moves to the end and is discharged, completing the debris separation. The clearance between each shaft can be customized according to actual needs.

| Modèle | Width(dm) | Length(dm) | Number Of Axes | Number Of Motor | Power(KW) | Capacité (t/h) |

| 0806 | 08 | 18 | 6 | 1 | 11 | 54-144 |

| 0808 | 08 | 24 | 8 | 1 | 15 | 72-192 |

| 0810 | 08 | 30 | 10 | 1 | 18.5 | 90-240 |

| 1010 | 10 | 30 | 10 | 2 | 11 | 112-300 |

| 1012 | 10 | 36 | 12 | 2 | 15 | 135-360 |

| 1014 | 10 | 42 | 14 | 2 | 15 | 158-420 |

| 1212 | 12 | 36 | 12 | 2 | 18.5 | 162-432 |

| 1214 | 12 | 42 | 14 | 2 | 18.5 | 189-504 |

| 1216 | 12 | 48 | 16 | 2 | 22 | 216-576 |

| 1318 | 13 | 54 | 18 | 3 | 18.5 | 263-702 |

| 1418 | 14 | 54 | 18 | 3 | 18.5 | 283-756 |

| 1518 | 15 | 54 | 18 | 3 | 22 | 303-810 |

| 1520 | 15 | 60 | 20 | 4 | 18.5 | 337-900 |

| 1620 | 16 | 60 | 20 | 4 | 18.5 | 360-960 |

| 1820 | 18 | 60 | 20 | 5 | 18.5 | 405-1080 |

Material properties (viscosity, moisture content, particle size distribution), feeding method (uniformity, speed), water pressure/volume (sufficiency, spray method), and operating parameters (like screen angle, vibration frequency) are crucial.

Pay attention to: pre-treatment (like adding water, breaking up clumps), choosing clog-resistant designs (trommels, bar screens, special separators), using ample high-pressure water for washing, controlling feed rate to prevent buildup. Multi-stage separation or dedicated clay washing equipment might be necessary.

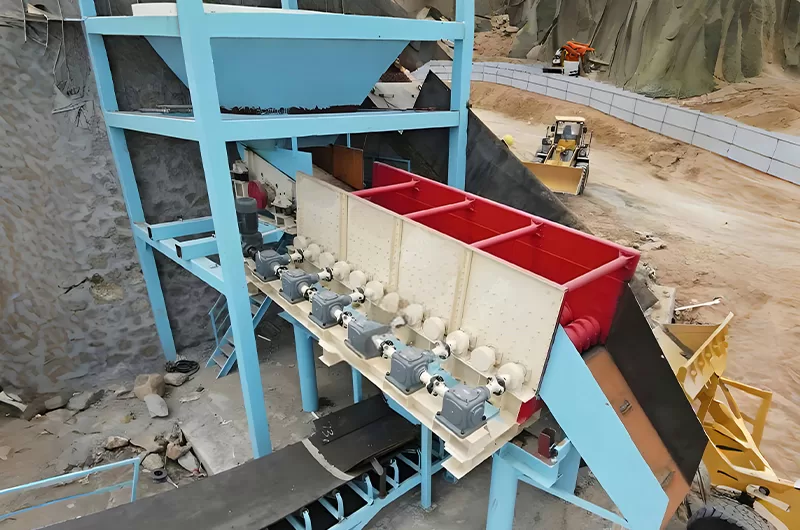

Upstream: Usually needs a feeder (e.g., apron feeder, vibrating feeder), sometimes a crusher for pre-treating large pieces. Downstream: Separated stones need conveyor belts for transport; the separated slurry needs to go to settling ponds, fine sand recovery units, filter presses, etc., for mud-water separation and wastewater treatment.

Common wear parts include: screen mesh/plates, bearings, nozzles, liners (if present), transmission parts (belts, chains, etc.). Replacement frequency depends on material abrasiveness, operating intensity, and equipment quality, varying from weeks to months. Key maintenance focuses on: regular inspection and tightening, bearing lubrication, screen tension and damage check, clearing blockages, ensuring waterways are clear