全站搜索

Search the entire website

Search the entire website

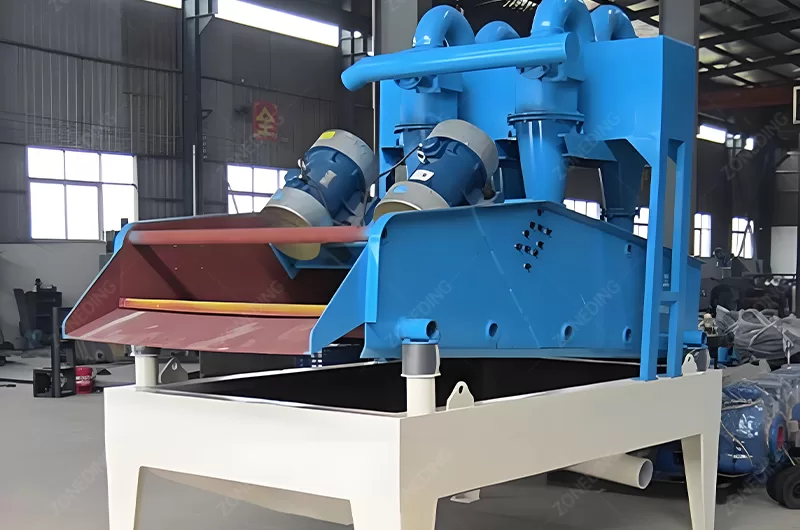

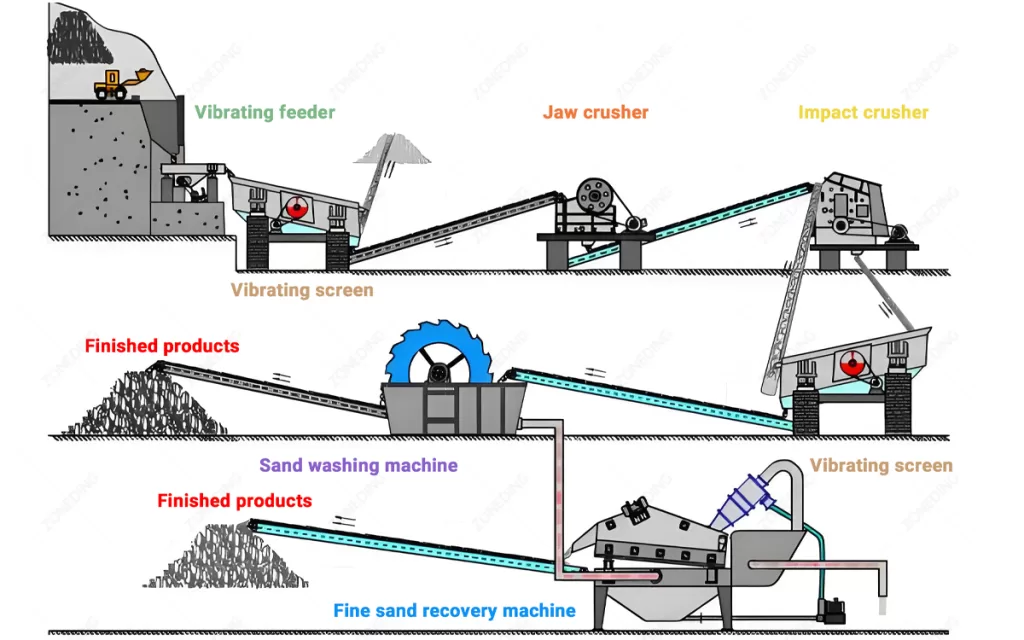

ZONEDING MACHINE manufactures mineral and material processing equipment. When washing sand or processing minerals, some valuable fine particles are often lost. These lost fine sands are carried away with wastewater. This is a problem, as it leads to product loss, incurs costs, and creates waste that is difficult to handle. ZONEDING MACHINE’s fine sand recycling machine is a specialized system. It captures these lost fine sands and converts waste into usable products. This helps increase output and save money. It is also better for the environment.

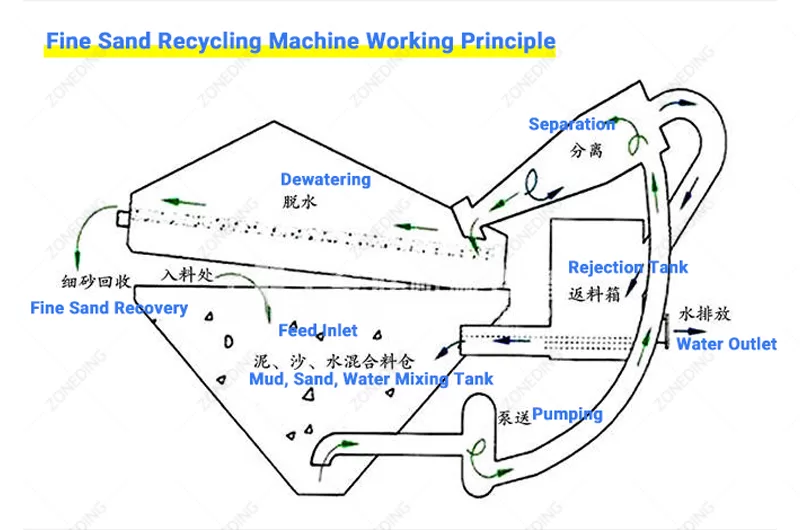

A Fine Sand Recycling Machine is a system designed to capture the fine sand particles that are lost in the overflow water from washing and processing equipment. It is like a filter and dryer for your wastewater. It takes the slurry, which is water mixed with these fine solids, and separates the valuable sand from the water. Its main goal is to “recycle” these fines. It brings them back into your main product stream.

The system works by concentrating the solids in the slurry. It uses clever technology to separate the heavier sand particles from the lighter water and very fine silt or clay. It then dewaters the sand. Dewatering means removing the water from the solid particles.

You end up with sand that is much drier and ready to be added back to your main product pile. This recovered fine sand has value. You can sell it. You can use it in your own concrete or asphalt mixes. By recovering this material, you increase your overall production yield. You get more sellable product from the same amount of raw material you start with. This directly improves your profitability. It makes your operation more efficient. It makes your operation produce less waste.

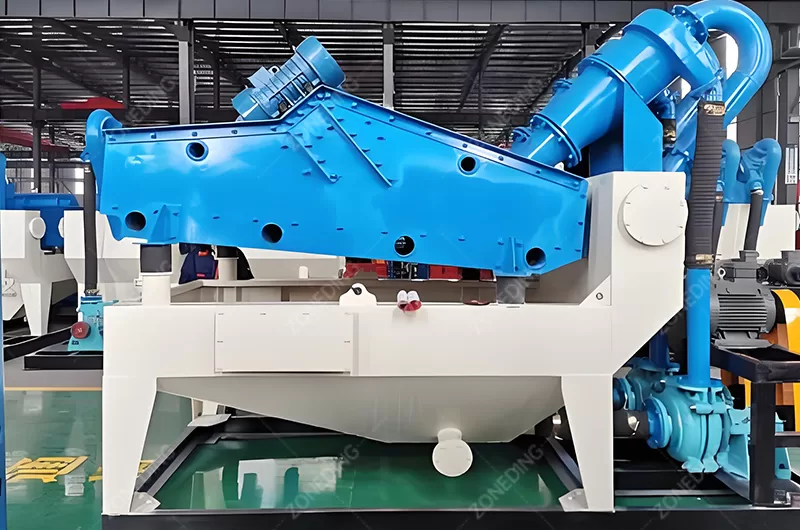

The Fine Sand Recycling Machine is not just one piece of equipment. It is usually a system made of a few key parts working together.

These parts form a chain that processes the slurry step-by-step. The main parts are typically a slurry pump or vacuum pump, a hydrocyclone or group of cyclones, and a dewatering screen. There is also a tank or sump to hold the slurry before processing.

First, the slurry pump or vacuum pump sucks the wastewater from your washing plant’s overflow or a collection tank. This pump needs to be strong enough to move the slurry, which can be thick and contains abrasive particles.

It sends the slurry under pressure to the next part. This next part is the hydrocyclone.

The hydrocyclone is like a cone turned upside down. The slurry enters the top part of the cone from the side. It spins around inside the cone very fast.

This spinning creates centrifugal force. Heavier particles, like fine sand, are pushed to the outside wall and move down the cone. They exit through a small opening at the bottom called the apex. The lighter water and very fine silt or clay particles stay in the center.

They flow upwards and out through a pipe at the top called the overflow. The cyclone separates the sand from most of the water and very fine waste. The sand coming out the bottom is still wet. The water coming out the top (overflow) is much cleaner and can often be reused.

The wet sand from the bottom of the cyclone goes to the dewatering screen. This is a special type of Vibrating Screen. It has fine mesh openings. The screen shakes very fast. The wet sand spreads out on the vibrating screen. The water passes through the mesh openings. The sand stays on top of the mesh. The vibration helps move the sand along the screen. It also helps the water drain away from the sand particles.

By the time the sand reaches the end of the screen, most of the water is gone. You get a pile of dewatered fine sand. The water that goes through the screen can be collected. This water usually contains some very fine particles that the cyclone did not catch. It can also be reused for washing, or sent for further treatment if needed. This combination of pump, cyclone, and screen efficiently captures and dewaters the fine sand.

Washing sand and gravel requires a large amount of water, leading to costs for purchasing fresh water and treating wastewater. In traditional methods, fine sand is lost to settling ponds with the water flow, and a large amount of water is trapped and difficult to recover, resulting in the continuous need to replenish fresh water, leading to high water costs, i.e., “washing turns into water bills”.

Fine sand recovery machines can effectively solve this problem by efficiently separating water and sand. The clean water overflowed from the hydrocyclone can be directly reused in the washing process, significantly reducing fresh water usage and lowering water bills.

Its main benefits include: significantly saving water costs; reducing wastewater discharge, shrinking the size of settling ponds and lowering maintenance costs; being more environmentally friendly, easily meeting regulatory requirements, and improving operational sustainability.

Water discharged from the dewatering screen can also be reused as appropriate (or after slight treatment). The entire system achieves closed-loop utilization of water resources by recovering sand and recycling water, which is both efficient and economical.

First, product output increases. By recovering sand that would otherwise be lost, the total amount of marketable sand is increased. If 10% of fine sand was previously lost, recovering 90% of it means the overall product yield is significantly improved. This is equivalent to adding extra capacity to the plant without increasing crushers or washing equipment. More product means more sales, directly increasing revenue. Many customers have seen a significant increase in final product output, sometimes boosting overall profitability by over 15% just through fine sand recycling.

Second, costs are reduced. Costs are reduced because more product is sold from the same raw materials, eliminating the need for additional raw material processing to compensate for lost fine sand. Water costs are also saved because washing water is recycled and fresh water usage is greatly reduced. Significant savings are also made on managing waste sedimentation ponds. As less sand and water enter the sedimentation pond, the pond fills up slower and requires less frequent cleaning. The total amount of waste requiring disposal is also greatly reduced. Less cleaning work means less labor, less excavator fuel, and less downtime. These cost savings accumulate significantly.

Third, it is more environmentally friendly. Reducing waste flowing to the sedimentation pond and recycling water are important environmental measures. They help obtain and maintain necessary operating permits and enhance the company’s image as a responsible enterprise. This is becoming increasingly important for acquiring business. Compared to the value of the recovered material, these machines are energy-efficient, making the entire production process more sustainable. Therefore, this investment pays off through higher sales, lower operating costs, and improved environmental compliance. These are the “visible” benefits that impact profitability.

Not all slurries are the same. The wastewater from washing granite aggregate is different from the slurry in a coal processing plant or a process dealing with very fine industrial sand. They have different particle sizes, different amounts of solids, and different material properties. To get the best results, you need a Fine Sand Recycling Machine that is right for your specific slurry.

Choosing the wrong model can mean poor recovery, sand that is too wet, or frequent clogging.

You need to look at a few key things about your slurry. What is the particle size distribution? This is very important. How much sand is in the target fine size range you want to recover? What is the cutoff size you need (the size above which particles are kept, and below which they are sent away)?

The cyclone part of the system is designed to separate particles at a specific size. If your target size is different, you need a different cyclone setup. What is the concentration of solids in your slurry? Is it thick or thin? The pump and the number and size of cyclones needed depend on the flow rate and the amount of solids you need to process per hour.

You also need to consider the required output. How much dewatered fine sand do you need to produce per hour? This affects the size of the dewatering screen and the capacity of the pump and cyclones.

What final moisture content do you need? While most dewatering screens get sand down to 10-20% moisture, some materials or downstream needs might require slightly different performance. The type of dewatering screen (like screen area, vibration strength, screen mesh type) can be adjusted.

We always recommend analyzing your slurry sample. We look at the particle sizes, the amount of solids, and other properties. Based on this analysis and your required capacity, we can choose the right combination of pump size, cyclone size and number, and dewatering screen size. We can customize the system components to match your specific slurry characteristics and production goals.

For example, if your slurry has a very high concentration of solids or a very high flow rate, you might need multiple cyclones working in parallel. If your material is particularly abrasive, we might recommend certain materials for the pump or cyclone parts to make them last longer. Picking the right model is key to high efficiency and reliable operation.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| ZD250 | ≤10 | 20-50 | 900*1800 | 250 | 12.5 | 3100*1300*2700 |

| ZD300 | ≤10 | 40-80 | 900*1800 | 300 | 16.5 | 3100*1300*2700 |

| ZD350 | ≤10 | 60-100 | 900*1800 | 350 | 20 | 3100*1300*2700 |

| ZD550 | ≤10 | 40-100 | 1200*2400 | 250*2 | 26.4 | 3600*1600*2800 |

| ZD650 | ≤10 | 80-160 | 1200*2400 | 300*2 | 34.4 | 3600*1600*2800 |

| ZD750 | ≤10 | 120-200 | 1200*2400 | 350*2 | 41.4 | 3600*1600*2800 |

| ZD900 | ≤10 | 120-250 | 1500*3000 | 300*3 | 51 | 4600*1900*2600 |

| ZD1050 | ≤10 | 150-300 | 1500*3000 | 350*3 | 61.5 | 4600*1900*2600 |

Like any industrial equipment, a Fine Sand Recycling Machine can have issues. But most common problems can be avoided or fixed with simple care and maintenance. Knowing what problems can happen helps you keep your machine running smoothly.

One common issue is the hydrocyclone getting blocked. This can happen if there are particles in the slurry that are too large for the cyclone’s inlet or apex (the bottom opening). It can also happen if the feed pressure from the pump is not steady or strong enough. Or, if the inner lining of the cyclone wears out unevenly, it can change the flow path and cause blockages. To prevent this, make sure your feed slurry does not have oversized particles.

You might need a simple sieve or screen before the pump. Keep the pump running at the correct pressure. Check the cyclone’s inner lining and apex regularly for wear and blockages. Replace worn parts quickly.

Another issue is the screen mesh on the dewatering screen breaking. This screen handles heavy, wet sand and vibrates strongly. The mesh is fine and can wear out, especially with abrasive sand. Improper tensioning of the mesh can also cause it to break faster. Vibration problems in the screen can put extra stress on the mesh and the frame.

To prevent this, use high-quality, durable screen mesh. Make sure the mesh is installed and tensioned correctly according to the manufacturer’s instructions. Regularly inspect the mesh for signs of wear or small tears. Replace it before it completely fails. Check the screen’s vibration system (motors, springs) to ensure it is working correctly and not causing uneven shaking.

The slurry pump can also wear out because it handles abrasive sand particles. The pump’s impeller and lining are exposed to constant wear. Regularly inspect the pump for wear. Have spare parts like impellers ready. Replacing worn pump parts on time maintains the correct pressure and flow rate to the cyclone, which is important for good separation.

General maintenance includes regular lubrication of moving parts (like the screen’s vibrator bearings), checking bolts and connections for tightness, and generally keeping the area clean. A simple daily check and a more detailed weekly or monthly inspection go a long way in preventing small issues from becoming big breakdowns.

Choosing the right supplier for your Fine Sand Recycling Machine is a very important decision. It is not just about getting a machine. It is about getting the right solution and getting good support over time.

A cheap machine that does not work well or breaks down often will cost you more in the long run. You need a supplier you can trust.

Look beyond the price tag. Consider their experience. Have they built and installed these systems for materials like yours before? Experience means they understand the challenges and know how to design a system that works. We have been making mineral processing equipment since 2004.

We have worked with many different materials and applications. Ask about their engineering team. Do they have skilled engineers who can customize the system for your specific slurry and site? A good supplier will analyze your material and design the best system size and configuration for you. Our engineers are experts in this.

Check the quality of the equipment they build. What materials do they use for the key parts? For the pump, cyclone lining, and screen mesh, you need materials that can handle abrasive sand. High-quality parts last longer. This means less maintenance and less downtime for you.

Visit their factory if possible, or ask for detailed photos and videos of their manufacturing process. Our factory is equipped to build robust, heavy-duty machines. Ask about their service package. Do they just sell you a machine, or do they help you install it? Do they train your workers on how to run and maintain it? What happens if something breaks? Do they have spare parts available? Do they provide troubleshooting support? A good supplier offers a full service, from helping you choose the machine to supporting you years after it is running. This support is very valuable. It helps you get the best performance from your machine and solve problems quickly.

A good Fine Sand Recycling Machine can typically recover 80% to 95% of the fine sand that enters the system. The exact percentage depends on the material and the system setup.

The sand from the dewatering screen is usually 10% to 20% moisture. This is dry enough for many uses, like conveyor transport or adding to concrete mixes.

The system is designed to separate sand from clay and silt. The very fine clay and silt usually stay in the cyclone’s overflow water and are sent away. The machine targets the fine sand particles, not the superfine clay and silt.

The main power use is for the slurry pump and the dewatering screen’s vibrator motors. Compared to the value of the recovered sand and the savings on water and waste management, the electricity cost is usually quite low. It is an energy-efficient way to recover product.