全站搜索

Search the entire website

Search the entire website

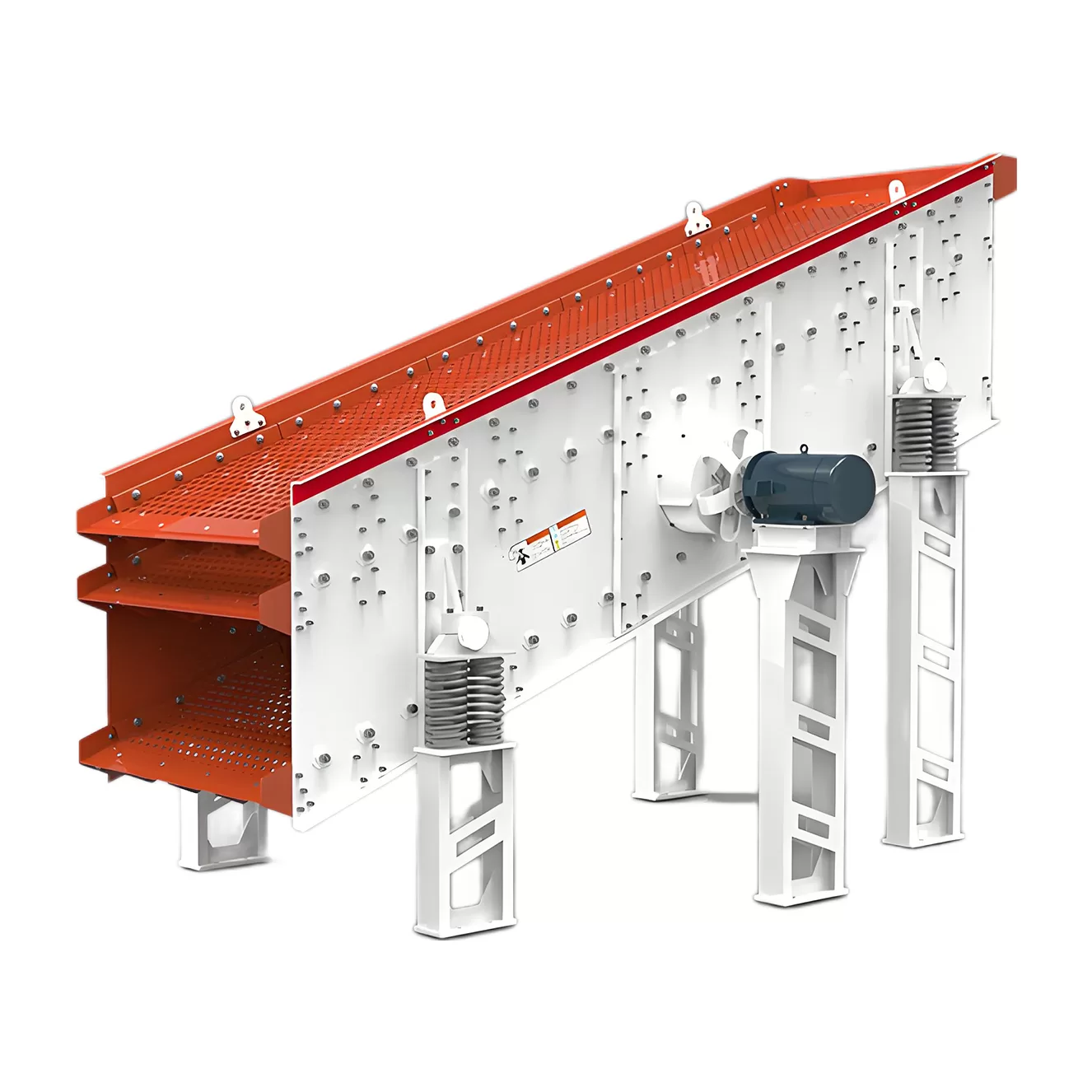

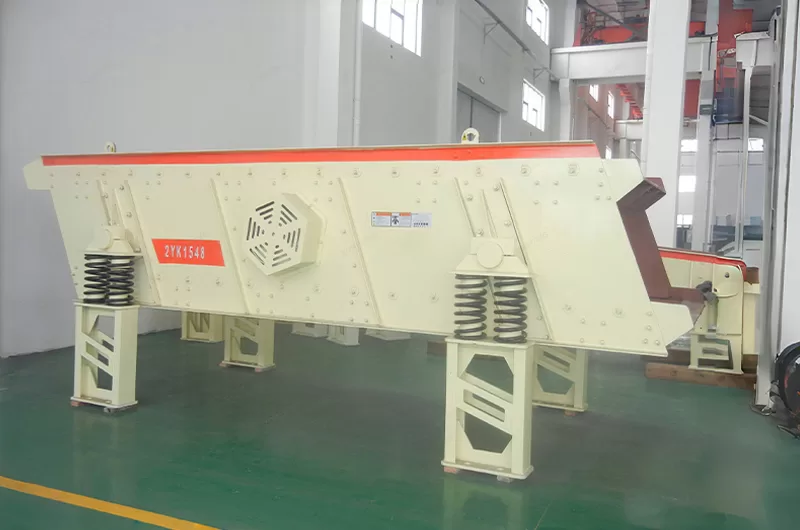

When the vibrating screen is screening material, the materials will do circular motion on the box, so it is also called circular vibrating screen.

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. which is main equipment to separate soild materials, it is widely used in mineral, building material, coal dressing,energy, chemical industry,etc.

A Vibrating Screen is a heavy-duty screening equipment used to separate raw materials into different sizes using vibration and gravity.

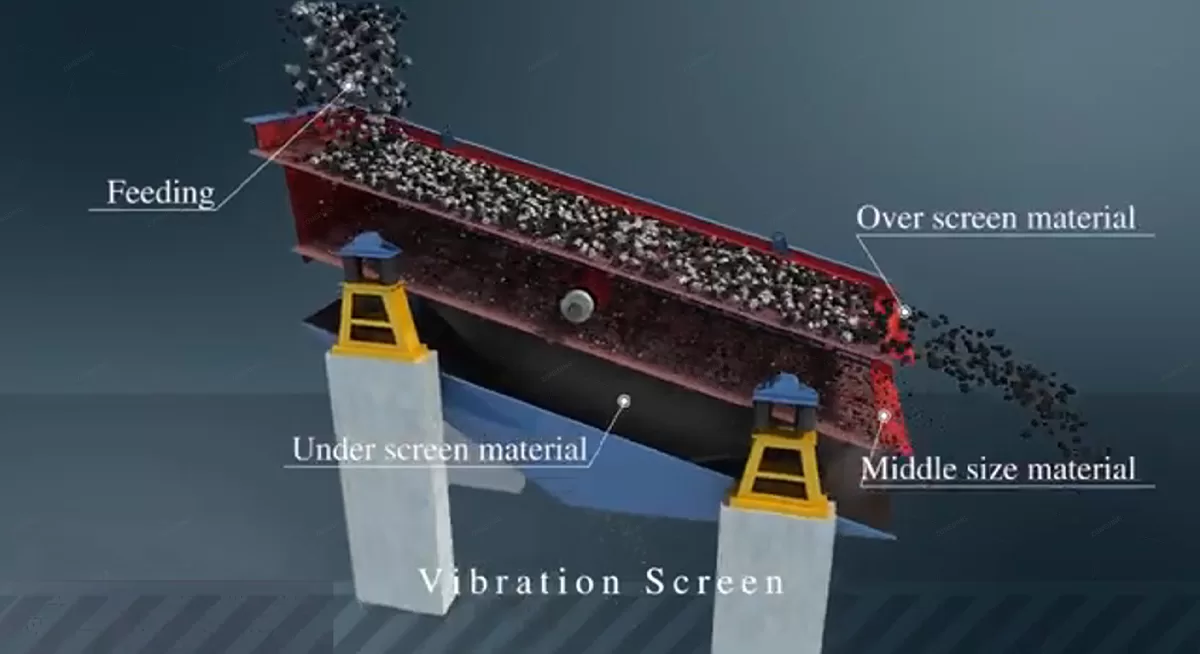

It sits after the primary or secondary crusher. The machine consists of a screen box that vibrates on a suspension system. As the material hits the vibrating deck, smaller particles fall through the holes (mesh), while larger particles travel across the top to the end of the machine.

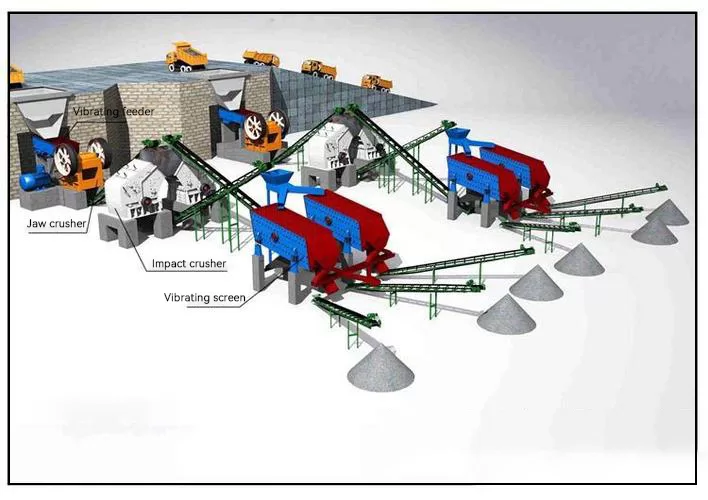

Think of it as a giant, automated sieve. Whether you need road base, railway ballast, or concrete sand, this machine ensures that every truck leaving your site carries exactly the size of stone the customer ordered.

Why do we use these specific machines instead of other separation methods?

While you mostly see them in quarries, their application is broad.

Not all screens shake the same way. The motion defines the application.

The vibrating sieve can be divided into mining vibrating screen, light fine vibrating screen, experimental vibrating screen, also can be divided into linear vibrating screen, circular vibrating screen, high frequency vibrating screen, double deck vibrating screen, single deck vibrating screen, and so on.

A vibrating screen is a necessary machine for mining and quarrying industries. In the quarrying field, the screening process always follows the primary and secondary crushing stages to divide rock material into more than three sizes from coarse to fine.

The working principle of a vibratring screen is quite simple. The crucial parts of the machine include vibrating screens, exciter, motor, screen decks, liners, and side plates.

Vibrating source comes from the exciter. During the process, the large material will stay on the top while the small and fine material can go throughout the screen mesh to the bottom, then you’ll get different sizes of materials.

| Model | Sieve layer | Sieve area (㎡) | Mesh size (mm) | Max. feeding size (mm) | Processing capacity (m³/h) | Vibrating Frequency (r/min) | Double amplitude (mm) | Motor power (kw) | Sieve obliquity (°) | Sieve specification (mm) | Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4270×1860×1210 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6230×2210×2060 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7600×3140×2380 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 750 | 6 | 6P 37 | 20 | 2800×6440 | 7600×4320×1620 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 750 | 6 | 6P 45 | 20 | 2800×6440 | 7800×4320×2120 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 750 | 6 | 6P 55 | 20 | 2800×6440 | 7800×4320×2120 |

Adjust amplitude/frequency for material type. Higher moisture/fines may need more aggressive action or specific screen media (e.g., self-cleaning). Ensure proper screen tension and regularly clean screen surfaces.

Higher open area in screen media boosts efficiency but often reduces wear life. Thicker wires/polyurethane extend life but may lower throughput. Select based on material abrasiveness, particle size, and desired capacity.

Amplitude (stroke) primarily affects particle lift, stratification, and dislodging near-size particles. Frequency (RPM) mainly controls material transport speed and the number of screening opportunities. Optimal performance requires balancing both.

Common causes include: overloading, incorrect screen deck angle or speed, screen blinding/pegging (causes fines in oversize), or damaged/worn screen media and insufficient bed depth (causes coarse in undersize).

Ensure even feed distribution to avoid imbalanced loads. Operate away from resonant frequencies. Regularly check and maintain tight fasteners (especially exciter and screen media bolts). Verify structural stiffness is adequate.