全站搜索

Search the entire website

Search the entire website

The Modular Impact Crusher Station combines tracked mobility with fixed-plant capacity. Its impact crushing ensures excellent particle shape. Perfect for Soft to Medium-Hard Rock or Construction Waste Recycling, it offers distinct flexibility and cost-efficiency based on superior engineering and metallurgy.

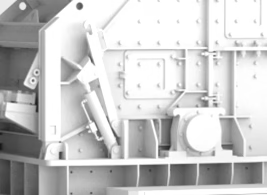

A Modular Impact Crusher Station is a pre-engineered, skid-mounted crushing unit designed for rapid deployment and foundation-free installation. Unlike a fixed plant that requires extensive concrete basements and anchor bolts, the modular station rests on a robust steel frame. This frame houses the Impact Crusher (Horizontal Shaft Impactor or HSI), the electric motor, drive guards, maintenance platforms, and the discharge chute.

The engineering behind a modular impact station differs significantly from compression-style crushers like Jaw Crushers. Jaw crushers generate vertical crushing forces that are easily absorbed by the ground. In contrast, an impact crusher generates massive horizontal kinetic forces. The rotor, spinning at high RPM, throws heavy rock against the impact aprons. This action creates a strong recoil effect.

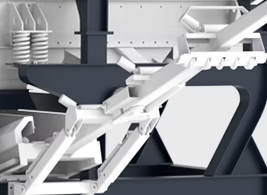

If the modular frame lacks sufficient rigidity, this horizontal energy causes the entire station to oscillate or “rack.” To counteract this, properly designed modular stations feature heavy-duty Diagonal Bracing within the steel skid. This triangulation distributes the horizontal shear forces, preventing fatigue cracking in the welds and shearing of the positioning bolts. Installation protocols often require embedding horizontal limiters or “stopper blocks” in the ground pad to physically lock the skid in place, ensuring stability during the processing of large feed materials.

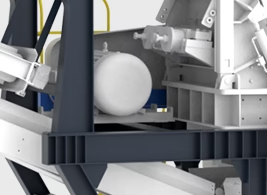

The heart of the station is the heavy-duty rotor. This component possesses immense rotational inertia. Even after the main motor power is cut, the rotor acts as a flywheel and can continue to spin for up to 20 minutes. This characteristic presents a critical safety challenge in remote modular operations.

Advanced modular stations integrate Zero-Speed Interlock systems. Sensors monitor the rotor shaft rotation. The electrical control panel interlocks the hydraulic access doors with these sensors. The hydraulic solenoids that open the crusher body for maintenance will not energize until the sensor confirms the rotor has come to a complete mechanical stop. This engineering feature eliminates the risk of operators accessing the crushing chamber while lethal kinetic energy remains in the system.

The compact nature of modular stations often imposes height restrictions for transport. This can lead to compromised discharge chute designs with shallow angles. For applications involving sticky materials, such as wet limestone or clay-contaminated feed, a standard steel chute will experience material buildup and blockage.

Optimized modular stations utilize UHMWPE (Ultra-High Molecular Weight Polyethylene) liners in the discharge zone. This material provides a low-friction surface that prevents wet fines from adhering to the chute walls, ensuring continuous flow. Furthermore, the design avoids “stone box” configurations (which trap material to form a wear layer) in sticky applications, as these promote clogging.

The selection of a modular impact station over compression crushers is driven by specific product requirements and operational efficiencies.

The primary advantage lies in the product shape. Compression crushers (cones and jaws) often produce elongated or flaky particles, especially when the reduction ratio is high. These particles create weak points in concrete and asphalt mixtures.

The impact crusher utilizes high-velocity impact energy. This force shatters the rock along its natural internal grain boundaries and eliminates internal stresses. The result is Cubical Aggregate with a low Flakiness Index. Cubical particles interlock better in concrete matrices, requiring less cement paste to fill voids and providing higher structural strength in the final construction project.

A modular impactor delivers a significantly higher reduction ratio than compression machines. A single unit can often reduce 500mm feed material down to 40mm in a single pass. This capability allows the impactor to function as both a primary and secondary crusher in soft rock applications. This simplifies the overall plant design by eliminating the need for multiple crushing stages and intermediate conveyors, thereby reducing the initial investment and maintenance complexity.

In Construction Waste Recycling, the modular impact station excels at material separation. Concrete and asphalt have a lower binding strength than the steel reinforcement bars (rebar) contained within them. Upon impact, the concrete shatters completely, liberating the rebar. The steel remains largely intact and does not break into small pieces. This difference allows for efficient downstream separation using magnetic separators suspended over the discharge conveyor. Compression crushers, by contrast, would merely flatten the concrete around the steel or become blocked by the metal.

Modern modular stations benefit greatly from Variable Frequency Drives (VFD). Impact crushers naturally produce a higher percentage of fines (0-5mm material). By equipping the main motor with a VFD, operators can precisely adjust the rotor tip speed.

The decision matrix for equipment deployment involves three factors: Capital Expenditure (CAPEX), Operational Expenditure (OPEX), and project duration.

| Feature | Tracked (Mobile) | Modular (Skid) | Fixed (Static) |

|---|---|---|---|

| Power Source | Diesel / Hydraulic | Grid Electric | Grid Electric |

| Mobility | High (Self-Propelled) | Medium (Crane/Truck) | None |

| Civil Works | None | Minimal (Compacted Base) | Extensive (Concrete) |

| Energy Cost | High | Low | Low |

| Resale Value | High | High | Low (Sunk Cost) |

Tracked Impact Crushers carry a premium price tag due to the inclusion of diesel engines, hydraulic drive systems, track frames, and onboard PLCs. A modular station removes these expensive components, relying instead on standard electric motors and a static steel frame. For the same crushing capacity, a modular station typically costs 30-40% less than its tracked counterpart.

The operational cost differential is substantial. Tracked units rely on diesel engines, which have high fuel consumption rates and require frequent maintenance (filters, oil changes, hydraulic services). Modular stations run on grid electricity or a single large generator. Electric motors are inherently more efficient, offer consistent torque, and require minimal maintenance. Over a 3-year project lifespan, the energy savings from using mains electricity can equal the initial cost of the crusher itself.

Fixed plants involve significant “sunk costs” in the form of concrete foundations, retaining walls, and permanent steel structures. Once the project concludes or the quarry reserve is depleted, these costs cannot be recovered. Modular stations utilize a “bolt-together” design. When the site is finished, the station is dismantled into shipping-container-sized modules and transported to the next location. This retains the asset value and provides flexibility for medium-term contracts (1-5 years) where a permanent plant is not financially viable.

The application range of a modular impact station is strictly defined by the geological properties of the feed material. Misapplication leads to excessive wear costs that can destroy project profitability.

The primary determinant for impact crusher suitability is the Silica (SiO2) content and the Abrasiveness Index of the rock.

Standard modular stations are often shipped with High Manganese (Mn13Cr2) blow bars. While tough, manganese steel has poor wear resistance against abrasion. For modular stations operating in a controlled secondary or tertiary role, upgrading the metallurgy is essential.

Modular impact stations are the industry standard for recycling. The feed material—concrete, brick, and asphalt—is relatively soft and abrasive but contains uncrushable contaminants like steel. The impactor’s ability to allow metal to pass through (with the help of a spring-loaded or hydraulic impact apron retraction system) without damaging the rotor makes it superior to cone crushers, which can suffer major mechanical damage from tramp metal.

A crusher rarely operates in isolation. To produce specification-grade aggregate, the modular impact station must be integrated into a closed-circuit system with a screening module.

In a closed-circuit configuration, the material discharged from the impact crusher is conveyed to a Vibrating Screen. The screen separates the material into finished products (e.g., 20mm, 10mm, 5mm) and oversize material (e.g., +20mm). The oversize material is directed onto a recirculation conveyor and returned to the impact crusher for another pass. This ensures 100% of the final product meets the required size specification.

Integrating two modular stations requires careful spatial planning.

The recirculated material increases the total throughput load on the crusher. If the crushing gap is set too tight, the volume of recirculated material increases, potentially overloading the main motor.

Modular stations can be easily encapsulated. Connecting the crusher module and the screen module with enclosed conveyors and installing a central dust collection system is straightforward due to the static nature of the frames. This allows the modular plant to meet strict urban environmental regulations, which is often difficult for open-air mobile equipment.

ZONEDING is a leading manufacturer of mineral processing equipment, dedicated to providing robust and efficient crushing solutions. From complete Stone Crushing Lines to individual modular stations, ZONEDING combines decades of engineering expertise with practical field experience. The company supports global clients with tailored equipment designs that prioritize durability, product quality, and cost-effectiveness in mining and recycling operations.

Using an impact crusher as the primary reduction method for river pebbles is economically unviable due to high silica content. The abrasive nature of the rock causes rapid wear of blow bars. It should only be used as a tertiary “shaping” crusher with a small reduction ratio to improve particle shape; a cone crusher is preferred for the main workload.

This depends entirely on the material properties. For soft limestone, blow bars may last 500+ hours. For abrasive concrete mixed with sand, they may last 150-200 hours. In high-silica applications, life can drop below 50 hours. Upgrading to Ceramic Matrix bars can extend this lifespan significantly.

Yes, a mobile crane is generally required to lift the skid off the transport truck and place it onto the prepared pad. However, unlike fixed plants, the assembly is rapid and does not require complex alignment, often completed within a few days.

Yes, modular stations are electric-drive and can run off a suitably sized diesel generator set (Gen-set) in remote locations. This setup is often more fuel-efficient and requires less maintenance than a diesel-hydraulic engine found on tracked mobile crushers.

The impact crusher produces superior cubical aggregate with a low flakiness index, which is highly valued for concrete and asphalt production. Cone crushers, operating on compression principles, tend to produce more elongated or flaky needles, often requiring a VSI crusher for final shaping.