全站搜索

Search the entire website

Search the entire website

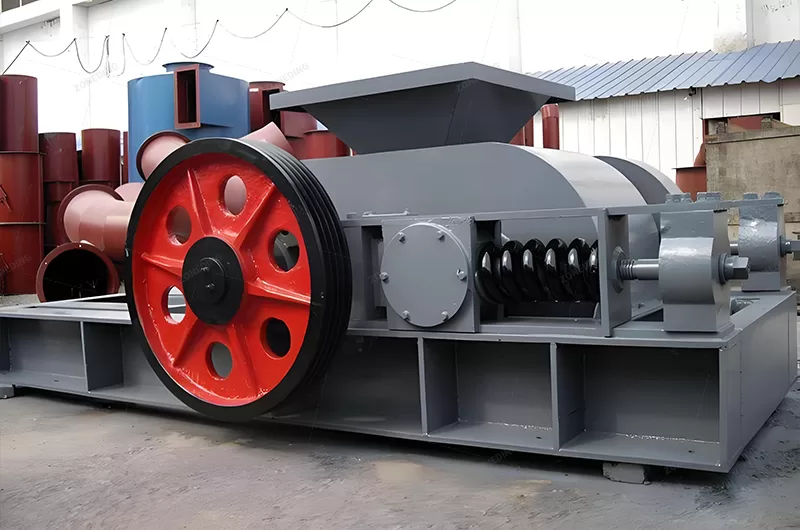

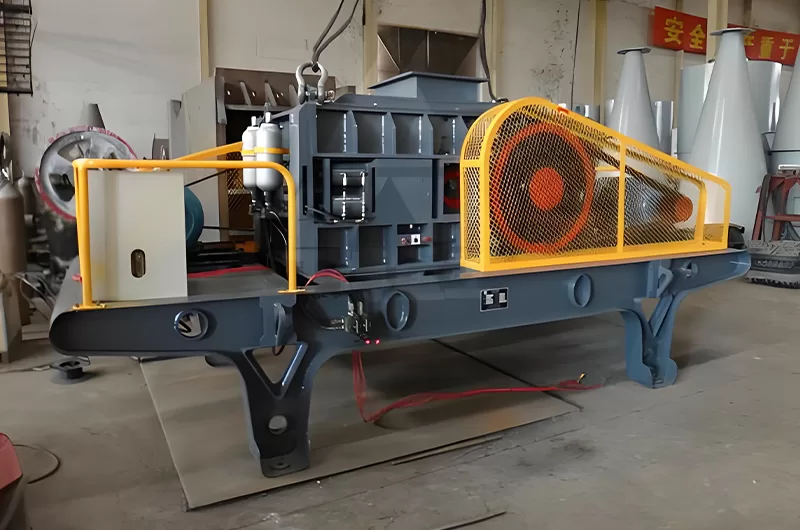

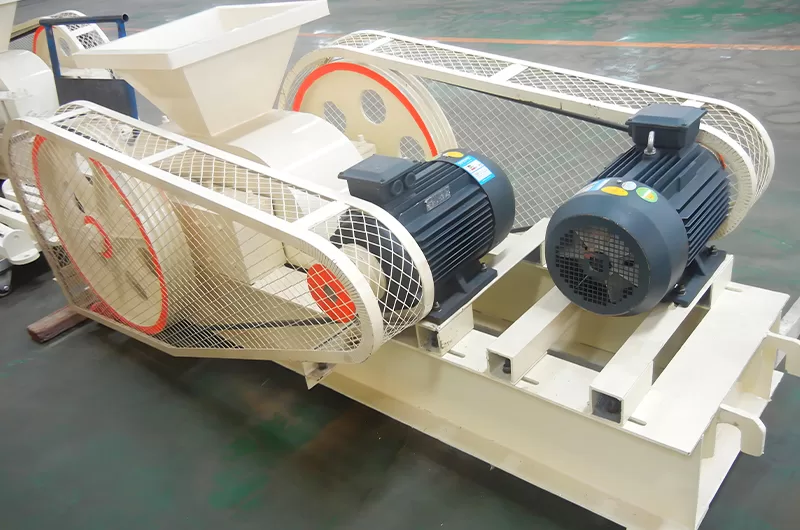

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc.

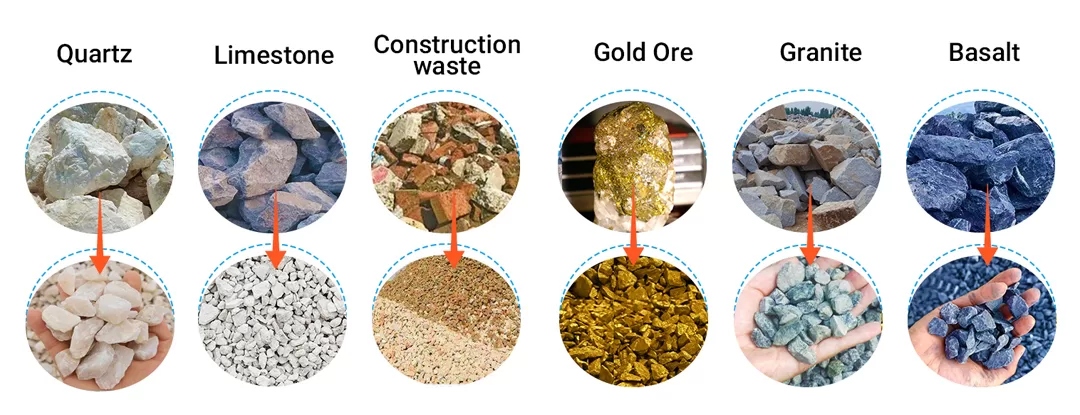

Roll crusher, as one of the most economical and practical crushers, is designed to handle the first and second crushing of friable minerals and stones such as coal, clay, coal gangue, limestone, slag, cement clinkers, and shale, etc.

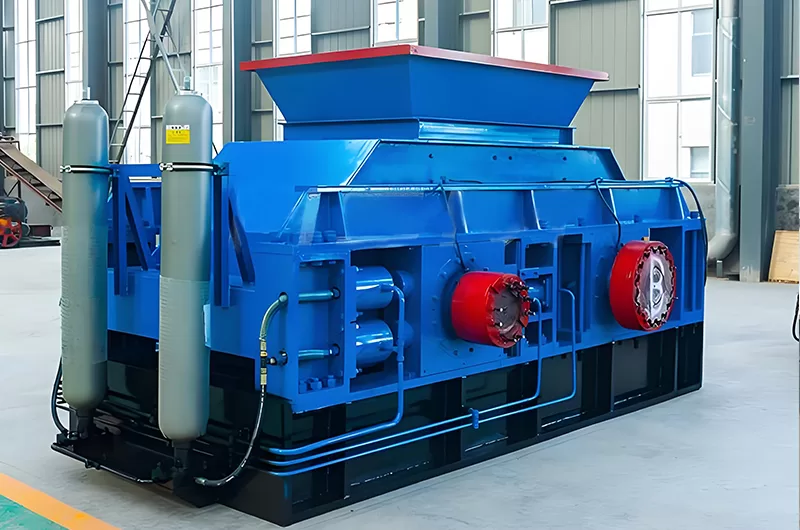

A Roll Crusher is a standard crushing machine that uses high compression to break rocks. Two heavy metal cylinders spin in opposite directions to crush the fed material.

Plant operators usually put this machine at the end of a crushing line. It works perfectly for secondary or tertiary crushing stages. The standard machine goes by the name 2PG Roll Crusher. Engineers designed it to handle materials with medium or low hardness. The design is very simple and easy to understand. You will find very few complex electronic parts inside.

The main purpose of this equipment is controlling the product shape and reducing dust. High-speed crushers shatter rocks into tiny dust particles. The dual cylinders only squeeze the rock once. The rock breaks into a neat shape and immediately drops out of the machine. This action makes it the ultimate low fines crusher. Plants that process glass, coal, or fertilizers rely entirely on this simple squeezing action to protect their product value. You protect your profit margins by creating less waste dust.

Roll Crusher is suitable forRiver gravel, iron ore, limestone, basalt, quartz, granite and other medium or hard ores and rocks in metallurgy industry, cement industry, power department, construction, phosphate, refractory industry, etc.

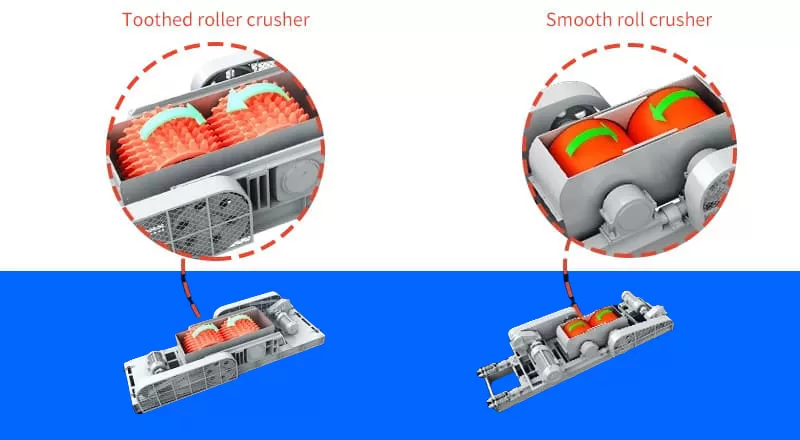

The counter-roller crusher pulls the material on the roller surface into the crushing cavity, so that the material is crushed by the stress mainly caused by squeezing, and is taken out of the crushing cavity by the rotating roller and discharged as the crushed product.

According to the surface of rolls, it can be divided into smooth roll crusher and toothed roll crusher. (The following roll crusher refers to “smooth roll crusher”.)

Our company produces 3 types of roll breakers: Roller crushers,Toothed rollers and hydraulic rollers.

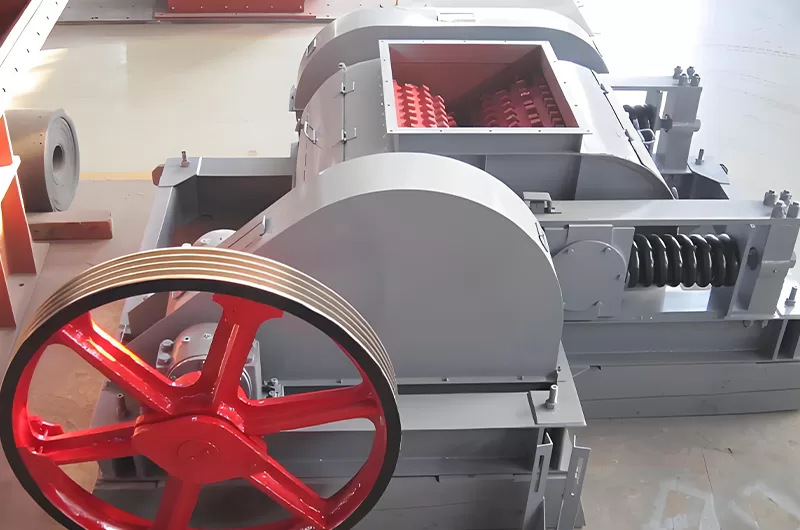

The main working parts of the roller crusher is the cylindrical rollers. The rollers are supported by the fixed and movable bearings, and they are relatively rotating which are driven by the motor. The materials are crushed by the friction of the rotating rollers, and the finished products are discharged from the gap of the rollers.

The spring is used to balance the pressure generated between the rolls. If there are non-crushed materials falling between the two rollers, the compression spring of bearings can be pushed to make a large gap so that non-crushed materials can be discharged immediately.

After the non-crushed materials are discharged, the spring can help recover the gap between the rollers to the original condition and the roll crusher continues to work.

| Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

| Roller Diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

| Roller Width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

| Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

| Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

| Processing Capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

| Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

| Motor Power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

A roll crusher uses compression to crush materials between rotating rolls. Often used for soft to medium-hard materials like coal, limestone, and aggregates. Excellent for size reduction.

Roll crushers provide a consistent product size, generate minimal fines, and are relatively simple to operate and maintain. Achieve a uniform crushed product.

Feed size depends on the model, but typically roll crushers handle materials up to several inches in diameter, reducing them to smaller sizes. Ideal for secondary crushing applications.

Output size is adjusted by changing the gap between the rolls. Smaller gaps result in finer output. Control your crushing output by managing roll spacing.

Regular maintenance includes inspecting and replacing worn rolls, lubricating bearings, and checking the drive system. Prolong the life of your roll crusher with regular upkeep.