全站搜索

Search the entire website

Search the entire website

The crusher functions as the processing center of a mining operation. The Modular Screening Plant functions as the revenue center. Crushers reduce rock size. Screening plants determine product specifications and marketability. Inefficient screening causes recirculation of sellable stone or production of oversized material. This text analyzes structural dynamics, media selection, and operational economics.

A Modular Screening Plant constitutes a pre-engineered aggregate classification system. The unit consists of a high-performance Vibrating Screen mounted on a galvanized steel skid structure. The assembly includes walkways, handrails, feed boxes, discharge chutes, and under-screen conveyors. The design eliminates the requirement for permanent concrete foundations found in static plants. The design removes the tracks and engines found in mobile plants. The module arrives in containerized sections. Installation involves bolting sections together on a compacted surface or concrete pad.

The system targets medium to large-scale mining projects. These projects require higher production volumes than mobile units provide. The projects require faster installation times than static plants offer. The modular approach standardizes the engineering. Standardized engineering reduces lead times for manufacturing. The structure supports various screen types. Options include inclined circular motion screens and horizontal linear motion screens. The primary function involves the separation of crushed material into distinct particle size fractions.

The skid structure supports dynamic loads. The vibrating screen generates G-force. This force transfers to the steel frame. The design utilizes finite element analysis (FEA). FEA identifies stress concentration points. The structure distributes these loads to the ground. Proper leveling prevents twisting. Twisting causes uneven stress on the screen body. Uneven stress leads to premature side plate failure. The modular design incorporates lifting points. Cranes position the modules. The assembly process takes days rather than weeks.

The advantages extend beyond portability. The benefits involve specific engineering solutions to structural fatigue and operational costs.

Vibrating screens operate at specific frequencies. A common operating speed is 900 RPM. The steel support structure possesses a “Natural Frequency.” Resonance occurs when the operating frequency matches the natural frequency. The amplitude of vibration increases drastically. This destroys steel welds.

The danger zone exists during start-up and shut-down. The screen speed ramps up from 0 to 900 RPM. The frequency sweeps through the natural frequency of the structure. The structure experiences a “transient shock.” This happens twice per shift. Repeated shock leads to fatigue failure. Steel beams crack. Welds separate.

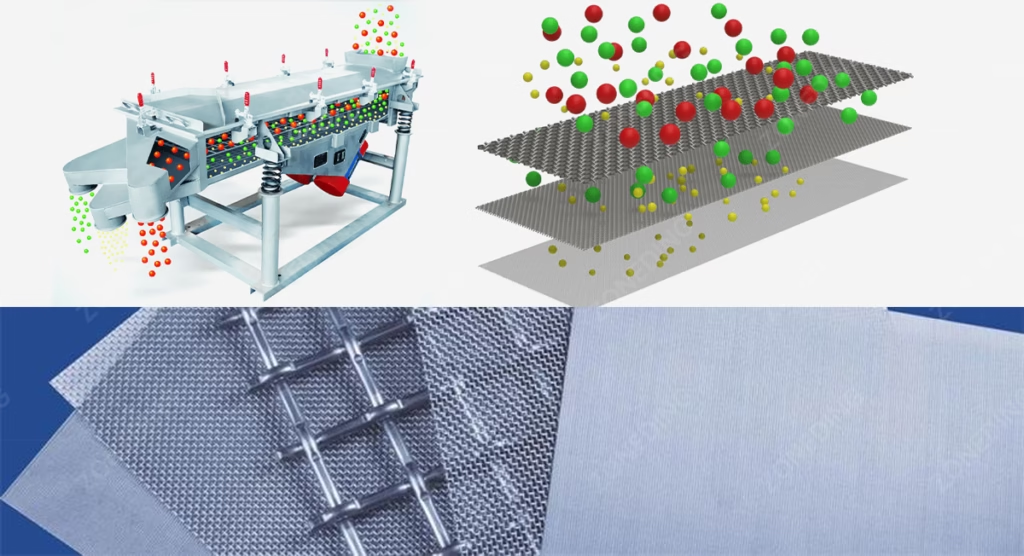

High-quality modular plants utilize Isolation Frames. The screen sits on a sub-frame. The sub-frame sits on the main structure. Rubber Isolation Springs or composite springs separate the layers. These springs provide higher damping than steel coil springs. The isolation frame absorbs 95% of the dynamic stress. The main static structure remains stable. This design extends the structural lifespan by years.

Chute maintenance represents a significant downtime factor. Abrasive stone wears through steel liners. Replacement requires cutting and welding in confined spaces.

The “Rock Box” or “Dead Bed” design solves this. The chute geometry includes ledges or steps. Material accumulates on these ledges. Incoming rock impacts the accumulated stone layer. Rock impacts rock. Rock does not impact steel. The stone layer acts as a renewable wear liner. The steel structure remains untouched. This design approaches zero maintenance.

Flat steel chutes require frequent liner changes. Lined chutes incur high parts costs. Rock box chutes utilize the processed material for protection. This reduces the total cost of ownership. The design requires precise calculation of flow angles. Material must build up but not block the flow.

Modular plants offer greater discharge height than tracked mobile units. Tracked units have height restrictions for transport. Modular units stand on legs.

Increased discharge height results in larger stockpile capacity. The volume of a conical stockpile increases with the cube of the height. A 2-meter increase in height doubles the storage volume. Larger stockpiles reduce the frequency of material removal. Wheel loaders operate less frequently. Less loader operation reduces diesel consumption. Reduced loader traffic lowers labor costs. The initial steel cost for height yields long-term operational savings.

Mining operations often face a choice between flexibility and performance. Tracked mobile screens offer flexibility. Fixed screens offer performance. The modular plant occupies the middle ground. It addresses specific limitations of both alternatives.

Tracked mobile screens prioritize compactness. Manufacturers cram components into a transport envelope. This creates maintenance nightmares. The space between screen decks often measures 300mm to 400mm. Technicians cannot access the bottom deck. Changing bottom deck media requires removing the top deck media. This doubles the labor time.

The Modular Screening Plant follows the “500mm Rule.” The design ensures a minimum clearance of 500mm to 600mm between decks. Technicians access the bottom deck freely. Safety increases. Downtime decreases. The modular design removes the constraints of road transport dimensions. The plant allows for wider walkways. Wider walkways improve site safety compliance.

Traditional fixed plants require heavy concrete foundations. Civil works consume time. Concrete curing takes weeks. Site remediation requires demolition. This represents a sunk cost.

Modular plants utilize steel skids or concrete blocks. The skid spreads the load. Ground preparation involves compaction. Concrete pouring is minimal or unnecessary. This suits short-term mining rights. The operator moves the plant to a new site. The asset retains value. Fixed foundations retain no value. The modular station functions as a movable asset.

Mobile screens utilize smaller screen boxes. A standard mobile screen measures 5′ x 16′. A standard modular screen measures 6′ x 20′ or 8′ x 24′. The larger surface area increases capacity. Screening Efficiency improves with length. Material has more time to stratify. Near-size particles have more opportunities to pass through the mesh. The modular unit handles surges in feed rate better than compact mobile units.

Screen media selection dictates production rates. The choice involves a trade-off between wear life, open area, and plugging resistance. Operators often default to one type. This limits performance.

Polyurethane (PU) panels offer extreme durability. PU lasts ten times longer than steel wire. The limitation is Open Area. PU panels have wide borders for structural strength. The actual hole area is 30-40%. Woven wire mesh provides 60-70% open area.

Using PU on the entire deck reduces capacity. The screen becomes a bottleneck. The solution involves a “Hybrid Configuration.”

The material bed depth varies along the screen length. The feed end receives the impact. The bed depth is high. Stratification has not occurred. Screening efficiency is low. The discharge end has a thin bed depth.

Wet, sticky material blinds standard mesh. Mud bridges the square openings. The effective screen area drops to zero.

The crushing plant operates as a system. The modular screening plant acts as the traffic controller. It directs material flow based on size. It connects the Cone Crusher, the vertical shaft impactor, and the washing circuit.

The screen defines the closed circuit. Material passes through the crusher. The screen separates the product. Material larger than the specification is “Oversize.”

The modular plant directs oversize material to a return conveyor. This conveyor feeds the Secondary Cone Crusher. The load on this return belt is the “Circulating Load.” Control of this load is critical. A circulating load above 30-40% chokes the crusher. The screen efficiency determines this load. High screen efficiency reduces unnecessary crushing. This saves energy.

Material leaves the crusher conveyor at high speed. Direct impact on the screen mesh causes rapid wear. It forces material to the center. The sides of the screen remain empty.

The modular station includes an engineered Feed Box. The design features a vertical Backplate. Material impacts the backplate. Horizontal velocity drops to zero. Material falls vertically onto the start of the mesh. The material spreads across the full width. This utilizes 100% of the screening area. Uniform wear leads to longer media life.

A single modular station produces up to four products.

ZONEDING manufactures heavy-duty mineral processing equipment. The product line includes the Jaw Crusher, Vibrating Screen, and complete modular solutions. The engineering focuses on durability and operational efficiency. Manufacturing takes place in an 8000 square meter facility. Engineers provide customized plant designs for global mining projects.

Uneven feeding causes twisting. Loose tension bolts cause vibration. Resonance during start-up causes fatigue. Proper isolation springs prevent this.

Inspect annually. Replace if height compresses by more than 10%. Replace all springs simultaneously to maintain level operation.

Yes. Spray bars mount on the deck. The structure must support the additional weight of water and piping. Verify static load limits.

A stroke amplitude of 8mm to 10mm works best. Larger separation requires larger stroke. Finer separation requires smaller stroke.

Modular plants typically require 7 to 10 days for mechanical assembly. Static plants often require 4 to 6 weeks for foundation curing and erection.