全站搜索

Search the entire website

Search the entire website

The sand washer produced by our company is the bucket type sand washing machine. It is the high efficiency washing equipment which uses advanced technology and combines the actual situations of the domestic sand industry.

Sand washing machine is artificial sand wet processing of the necessary equipment, which can effectively improve the quality of the finished sand. Our development and production of bucket sand washer and spiral sand washing machine combined with the actual situation of domestic and gravel industry, both cleaning, dewatering, grading three functions, widely used in metallurgy, building materials, utilities and other industries washing, grading, cleaning and other operations.

A Sand Washing Machine is specialized equipment used to remove impurities like dust, clay, and soil from sand to improve its quality.

It is usually the final stop in a crushing line. After the rocks are crushed by a VSI Sand Maker and screened, the “sand” is often covered in stone powder. The washer uses water and agitation to scrub the particles clean.

Think of it as a washing machine for rocks. It separates the heavy, clean sand from the light, useless mud. The result is a clean, dewatered product that meets strict ISO and ASTM construction standards.

Why spend money on water and electricity to wash stones? The answer is simple: Profit Margin.

The common types of sand washing machines on the market include spiral sand washing machines and impeller sand washing machines.

Main Features of Sand Washing Machine :

Main Features of Spiral Sand Washing Machine :

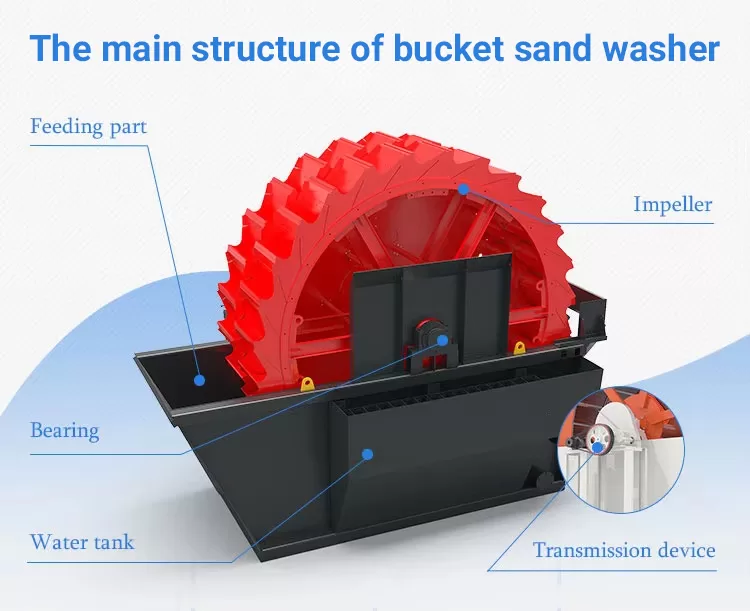

The sand washer adopts a wheel structure and consists of a feeding part, a transmission device, an impeller, a bearing, and a water tank.

Its power depends on models and how many impellers you use. Its types include single-wheel, double-wheel, and three-wheel, and there is no mobile type. The larger the impeller diameter, the higher the efficiency.

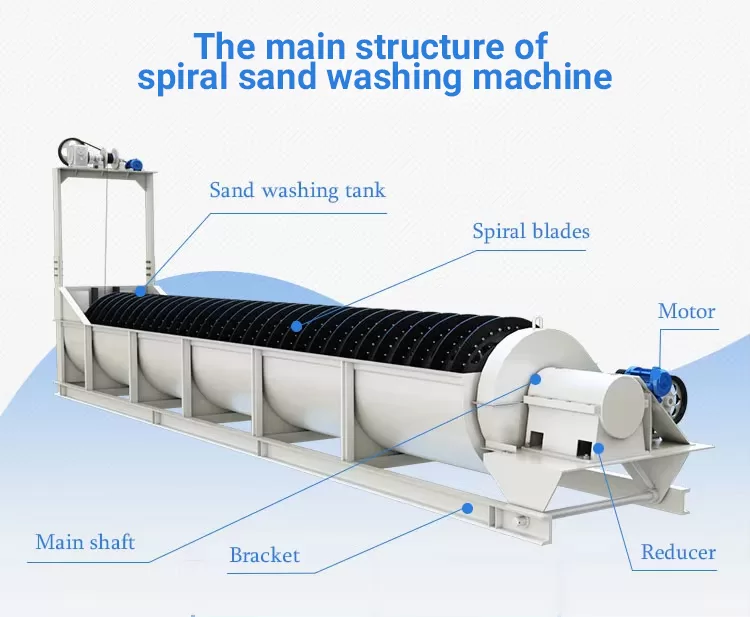

The rotor adopts a central structure. The spiral blade is installed on the main shaft and connected to the reducer to work. The impeller drives the bearing device to isolate the bearing from water and materials, ensuring that the finished product is not contaminated and effectively improving the cleaning effect.

Impeller sand washer is claso called wheel bucket sand washing machine. The sand and gravel are turned over under the drive of the wheel bucket, and grind each other to remove impurities on the surface. At the same time, add water to the inside of the machine to form a strong water flow, and take away the washed out impurities and other foreign objects with small specific gravity in time. The clean sand and gravel are taken away by the blades and poured into the discharge tank, thus completing the cleaning of the sand and gravel. It mainly includes single-row wheel bucket, double-row wheel bucket and three-row wheel bucket sand washing machine.

It often forms a high-quality sand production line together with a sand making machine, which is used in transportation, chemical industry, mining, and other fields.

The spiral sand washing machine mainly stirs the sand and gravel through the spiral device in the equipment, so that the sand and gravel are mixed with water. Then the sand and gravel are gradually screened under the action of the spiral, and discharged from the discharge port, thus realizing the cleaning and screening effect of the sand and gravel. In terms of type, it can be divided into two types: single-spiral sand washer and double-spiral sand washer.

It is mainly suitable for washing, grading and impurity removal in metallurgy, building materials, hydropower and other industries, especially suitable for construction sand and road construction sand.

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 2208 | 15-40 | 8p 4kw |

| 2611 | 20-65 | 8p 5.5kw |

| 2914 | 50-100 | 8p 7.5kw |

| 3020 | 80-200 | 8p 11kw |

| 3121 | 90-260 | 8p 11KW |

Wheel: better fines retention, gentler. Spiral: aggressive clay removal, higher fines loss risk.

Hydrocyclones, fine sand recovery units (dewatering screen + cyclone), thickeners & precise weir control.

Lower feed rate, optimize speed/weir, ensure adequate water. Test & adjust.

Buckets/spirals, liners, bearings. Use high-chrome iron, PU/rubber, & good seals.

Lower moisture, recovers ultra-fines, clarifies water for reuse, reduces pond load.