全站搜索

Search the entire website

Search the entire website

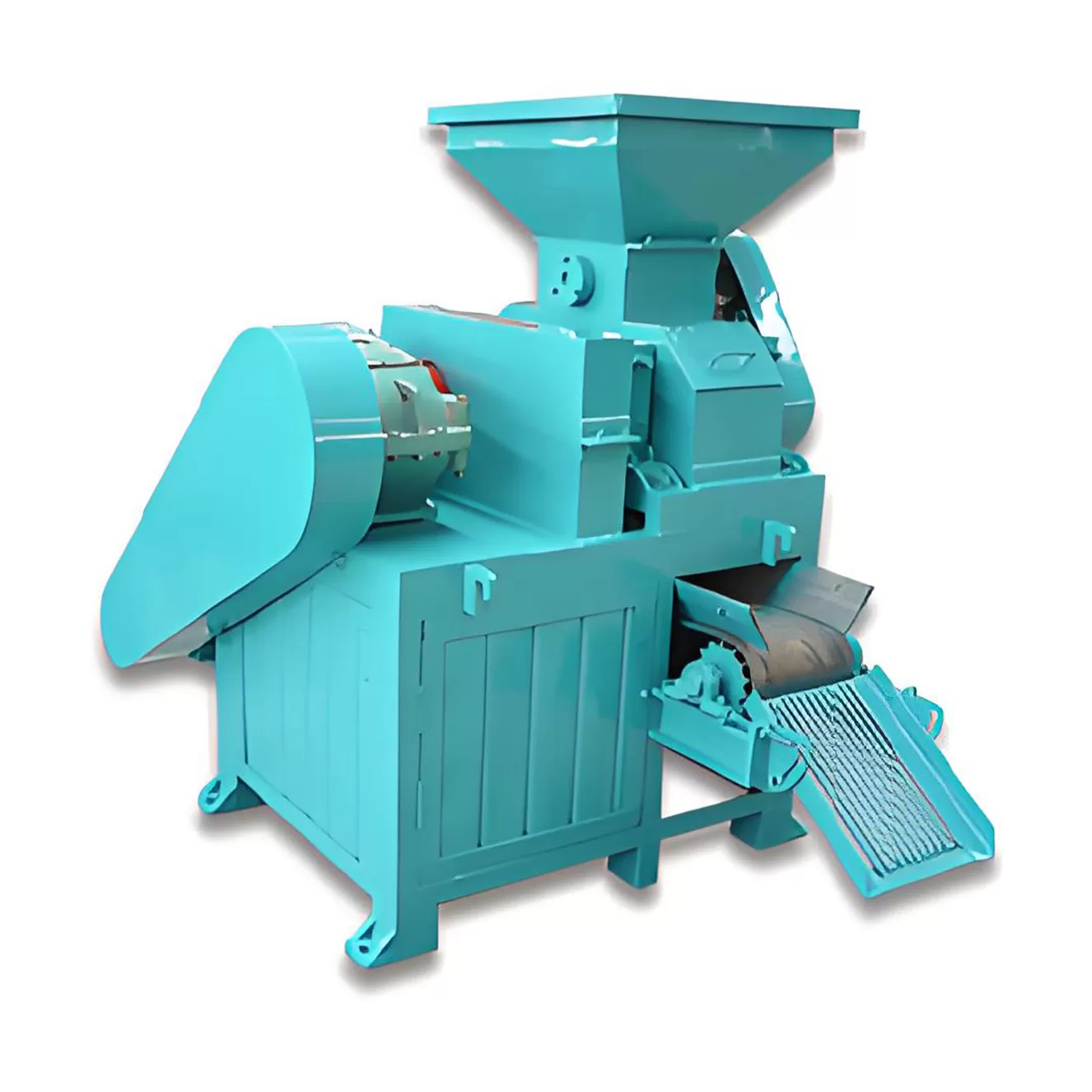

The coal briquette machine also known as coal dust briquette machine, can press fly ash or particle coal slime, raw coal and lignite into spherical, oval, flat shape, referred to as briquettes. The finished coal briquetting can be used in power generation, furnace calcination, daily life and other fields.

A coal briquette machine is a piece of equipment designed specifically to compress fine coal powder into solid blocks, called briquettes, using mechanical force. The most common type employs two counter-rotating rollers with matching pockets or molds.

Its main job is densification. It takes dusty, low-density fines and turns them into compact shapes (like pillow, oval, square) that are much easier to store, transport, and burn in a controlled way.

These machines primarily process coal fines (anthracite, bituminous, lignite, coal sludge), but also effectively briquette charcoal powder, coke fines, various mineral powders (iron, manganese, magnesium, chrome), flue gas desulfurization (FGD) gypsum, and even some chemical powders.

The coal briquette machine is mainly used for pressing materials with low moisture content, such as various coal briquettes, mineral powder and refractory materials. Pulverized coal briquetting machine and charred coal briquetting machine are suitable for refractory industry, power plant, metallurgy, chemical industry, energy, transportation, heating and other industries.

| Material Type | Common Application Sector | Primary Purpose |

|---|---|---|

| Coal Fines/Sludge | Fuel (Domestic & Industrial) | Heating, Steam Generation |

| Charcoal Powder | Fuel (Consumer) | Barbecue (BBQ) |

| Coke Fines | Metallurgy, Foundry | Fuel, Reducing Agent |

| Iron Ore Fines | Steelmaking | Furnace Feed |

| Manganese Ore Fines | Metallurgy | Alloying Agent Feed |

| FGD Gypsum | Construction Materials / Handling | Cement Additive, Disposal |

Essentially, anywhere fine powders need to be consolidated for easier handling, transport, or use, a briquette machine can be a solution.

Two rollers with matching pockets machined into their surfaces rotate towards each other. Powder fed from a hopper above is drawn into the gap (nip) between them. The intense pressure forces the powder into the pockets, compacting it into briquettes that are released as the pockets separate after the nip point.

Achieving strong, durable (high strength, good water resistance) briquettes requires optimizing several factors together: proper raw material preparation (particle size), correct binder selection and dosage, thorough mixing, precise moisture control, sufficient roller pressure, and critically, proper drying or curing after pressing.

Neglecting any of these steps, especially the drying process, will likely result in subpar briquettes that don’t meet handling or usage requirements.

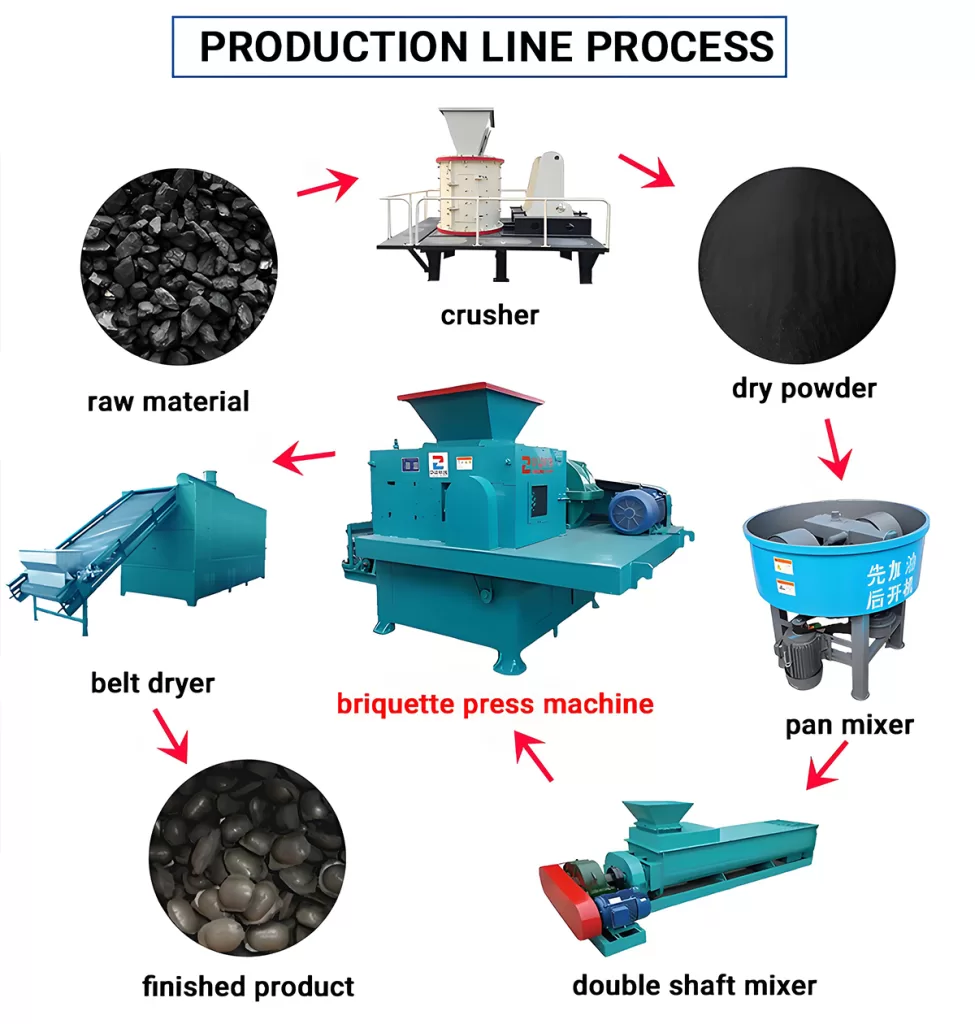

A single briquette machine is just one part of a larger system. A typical complete production line includes equipment for raw material crushing, screening, storage, binder preparation and mixing, the briquette machine itself, conveying systems, and usually a crucial drying system for the finished briquettes.

Based on the lines we design and build at ZONEDING, a standard setup involves:

Designing an efficient line requires considering the specific material, required capacity, and interactions between each piece of equipment.

Partnering with ZONEDING, a manufacturer with over 20 years of experience in briquetting technology, you get solid, well-engineered briquetting machines and complete production line solutions, backed by deep process knowledge, customization capabilities, strong manufacturing capabilities, and comprehensive support from initial design to long-term operation.

Choosing ZONEDING means choosing a partner committed to providing not just equipment, but a complete, reliable, and efficient briquetting solution tailored to your success.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

A normal roller briquette machine compacts loose materials into dense, uniform briquettes using rollers. It’s used for dust suppression, recycling, and making materials easier to handle. Improves briquette production.

This roller briquetter processes coal fines, charcoal powder, minerals, chemical powders, and other industrial wastes. It enables efficient material compaction and resource recovery from byproducts.

The machine uses two counter-rotating rollers with specially designed pockets. As the rollers turn, material is compressed into these pockets, forming the desired briquette shape. Simple, effective briquetting press.

A normal roller briquette machine is a standard design, known for its simplicity and cost-effectiveness. It’s a reliable choice for basic briquette making applications. It focuses on efficient compaction.