全站搜索

Search the entire website

Search the entire website

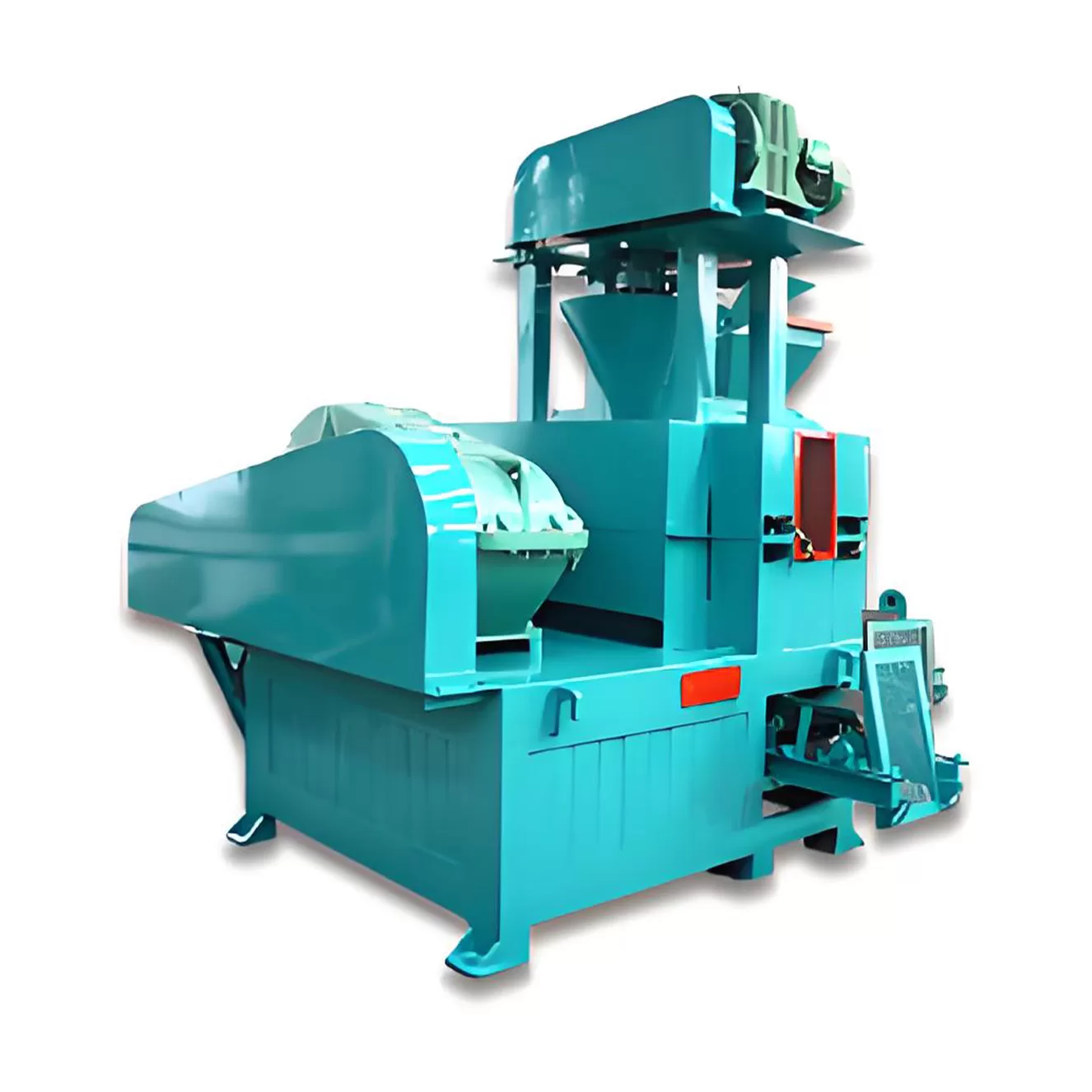

Use the hydraulic system to press a variety of powder materials that are difficult to form into balls.

A hydraulic dry powder briquette machine uses immense, controlled hydraulic pressure to compact fine, dry materials like mineral powders or metal fines into dense blocks (briquettes) without needing binders, improving handling and value.

Briquetting dry powders drastically reduces dust, cuts handling/transport volume and costs, minimizes material loss, improves storage, and optimizes downstream processes like furnace feeding by creating dense, uniform blocks.

Turning loose powder into solid briquettes offers substantial operational advantages, especially for industrial materials.

Choose hydraulic when extremely high, controllable pressure and potential dwell time are essential to compact difficult, binderless dry powders that cannot be formed effectively by standard mechanical roller presses.

The driving mechanism fundamentally changes the pressure characteristics and applications.

| Feature | Hydraulic Briquette Machine | Mechanical Roller Briquette Machine |

|---|---|---|

| Pressure Source | Hydraulic Cylinder (Piston/Ram) | Rotating Rolls driven by Motor/Reducer |

| Pressure Type | High Static Pressure (Area Pressure) | High Line Pressure (at Nip Point) |

| Pressure Level | Very High & Controllable (up to 200+ MPa) | Lower to Moderate (Pressure limited by roll gap) |

| Binder Needed | Typically No (Binderless Dry Pressing) | Often Yes (Water or binder usually required) |

| Dwell Time | Yes (Can hold pressure for set time) | Minimal (Instantaneous pressure at nip) |

| Output Rate | Lower (Cyclic Operation) | Higher (Continuous Operation) |

| Ideal For | Difficult-to-press, binderless powders needing extreme pressure, high density, precise shape; Lower volumes (Insight #3) | Materials needing less pressure, often with binder; High volume production |

Hydraulic isn’t always the default for dry powder. For very high volumes where achievable pressure is sufficient, specialized high-pressure roller presses might be more economical. Hydraulics excel where extreme unit pressure and dwell time are non-negotiable for achieving density in tough materials, or when precise shapes are paramount.

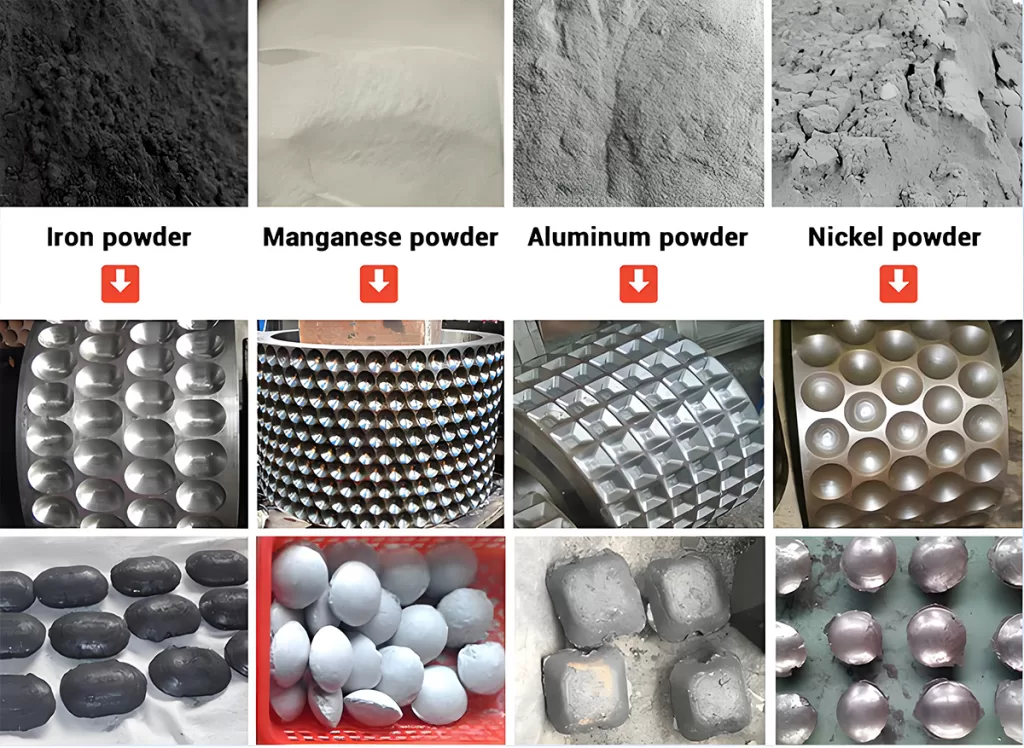

Hydraulic systems can deliver immense pressures, often exceeding 100-200 MPa (megapascals) or specific forces like >1000 tons, essential for compacting hard metal powders (iron, manganese, chrome), refractory oxides (magnesia, alumina), certain minerals (fluorite), and metal shavings without binders.

Almost all the powdery materials can be briquetted, here are some common materials:

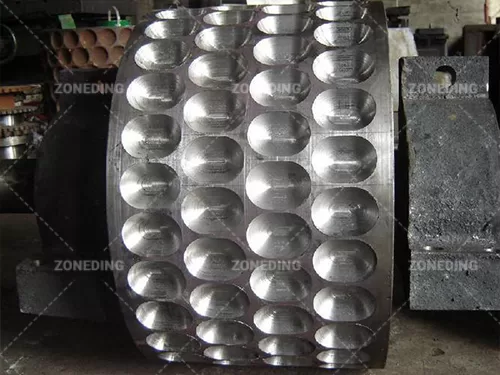

briquette shapes (pillow, square, round, oval, custom geometries) and sizes are highly customizable through the design of the press mold. Shape and size significantly impact stress distribution during pressing and ejection, influencing final density, strength, and the potential for defects like cracking.

When selecting shape and size, consider the downstream application, handling requirements, and the potential impact on pressing feasibility and briquette integrity. ZONEDING can work with you on mold designs optimized for your material and needs.

A hydraulic briquette machine uses a pump to pressurize oil, driving a main cylinder/ram. This ram forces a mold punch into a die filled with powder, applying immense, controlled pressure to compact the material binderlessly into a dense briquette.

| Model | Roller Diameter(mm) | Capacity(t/h) | Power(kw) | Reducer |

| ZDMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| ZDMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy ZDMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| ZDMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy ZDMQ430 | 430 | 5-8 | 15 | 500 |

| ZDMQ500 | 500 | 8-11 | 30 | 650 |

| ZDMQ650 | 650 | 10-15 | 37-45 | 750 |

| ZDMQ750 | 750 | 20-25 | 45 | 750 |

| ZDMQ850 | 850 | 20-28 | 55 | 850 |

| ZDMQ1000 | 1000 | 25-35 | 90 | 1000 |

This hydraulic briquette machine compacts dry powders into dense briquettes using hydraulic pressure. It eliminates the need for binders in many applications. Enables efficient dry powder briquetting.

The hydraulic press handles mineral powders, chemical powders, metal powders, and pharmaceutical ingredients. Achieve consistent briquette production from diverse dry materials.

Benefits include high briquette density, binderless briquetting, precise control over pressure, and reduced dust. Improved material densification & easy handling. Offers efficient material transformation.

The hydraulic system allows for precise pressure adjustments. Increasing hydraulic pressure leads to higher density briquettes. This enables control over briquette properties.