全站搜索

Search the entire website

Search the entire website

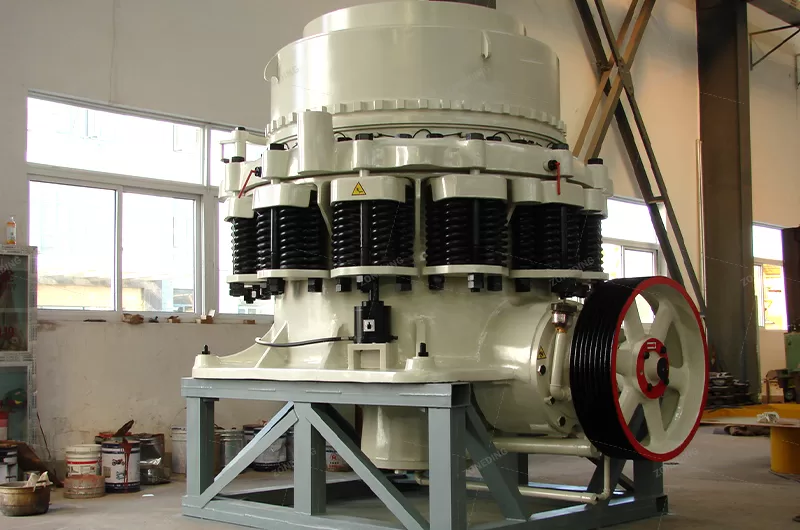

A medium and fine crushing equipment. The spring cone crusher is the insurance device that can also influence crushing force.

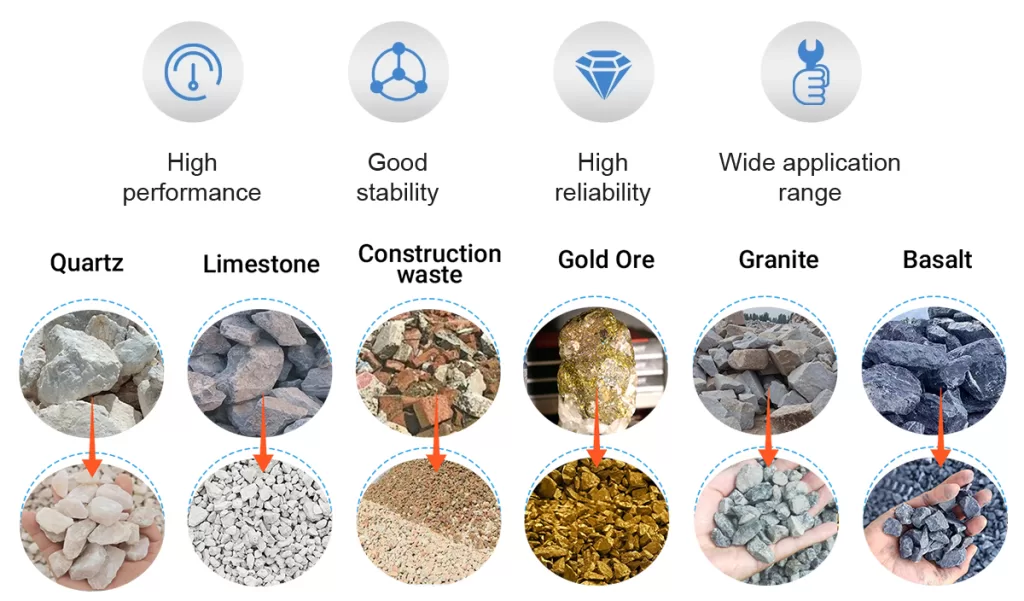

Spring cone crusher is a medium and fine crushing equipment, the spring is not only a safety device but also affects the crushing force. The crushing chamber type is determined by the ore use: the standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for ultrafine crushing. Spring cone crusher is suitable for crushing hard and medium hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase, etc., widely used in metallurgy, construction, road construction, chemistry and phosphate and other industries.

CS Spring Cone Crusher utilizes the lamination crushing principle, combining a high swing frequency, optimized cavity type, and rational stroke. This type of classic cone crusher is ideal for crushing hard materials such as granite, basalt, and river stones.CS Spring Cone Crusher utilizes the lamination crushing principle, combining a high swing frequency, optimized cavity type, and rational stroke. This type of classic cone crusher is ideal for crushing hard materials such as granite, basalt, and river stones.

Application: iron ore, granite, limestone, quartzite, sandstone, cobblestone and etc. CS Symons cone crusher is applied to cement mills, mining, building construction, road & bridge construction, railway construction and metallurgy, and some other industries. Materials like iron ore, granite, limestone, quartzite, sandstone, cobblestone, and some others are easily crushed by cone crusher.

A cone crusher is one of the most widely used mining equipment. Symons cone crusher as a medium or fine crusher used in the site where not require a high granularity standard. Since the Simmons cone crusher controls the product size by reducing the size of the discharge opening, it is not suitable for use for superfine crushing and sand-making operations.

Features

1. Easy maintenance and easy operation. The lamination crushing process makes the final material have a good particle shape.

2. The hydraulic overload protection device helps to remove iron and reduce downtime. The thin oil lubrication station is equipped with a cooling system for better cooling performance.

3. The standard or short head crushing chamber can be replaced by different sleeves and bowl liners to better meet the needs of users.

4. Heavy-duty design and use of high-quality components with optimized wear parts reduce operating costs.

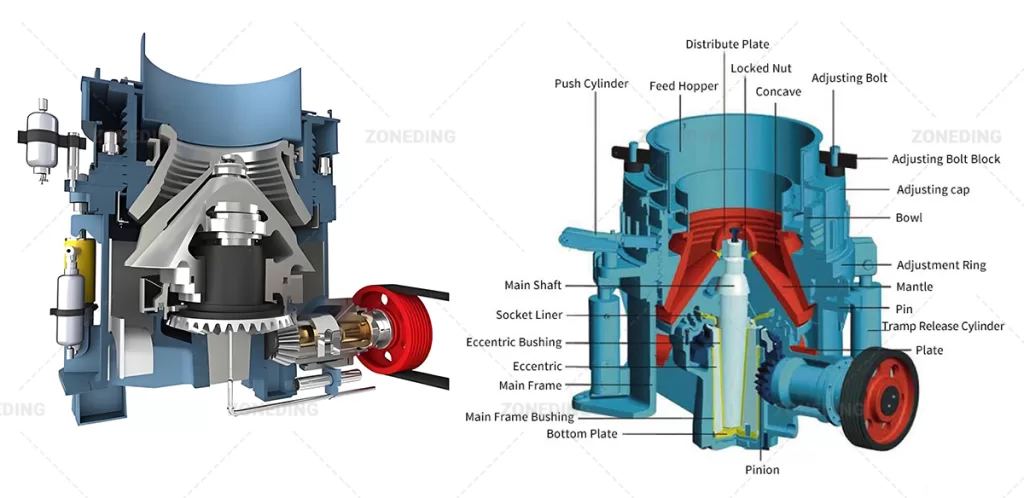

The structure of spring cone crusher is mainly composed of frame, fixed cone, moving cone assembly, spring mechanism, bowl shaft frame and transmission.

The working principle of the spring cone crusher commences when the electric motor is powered. This motor drives an intricate linkage of gears.The core action stems from the transmission gear driving the eccentric sleeve.

This rotation forces the moving cone (mantle) to execute a gyratory or eccentric pendulum-like motion , relative to the fixed cone (bowl liner). As the moving cone gyrates, the gap between it and the fixed cone constantly closes on one side while opening on the opposite. Material entering the crushing cavity is caught in this closing gap, where it undergoes intense compression, impacting, and crushing forces. As the gap widens on the other side, the crushed material falls lower into the chamber for further size reduction or discharge.

| Model | Moveable Cone Dia. (mm) | Cavity Type | Feeder Opening Size | Adjusting Range of Discharge Opening(mm) | Main Shaft Speed (r/min) | Motor Power (kw) | Capacity(t/h) | Overall Dimension L*W*H (mm) | |

| Shutting Size(mm) | Opening Size(mm) | ||||||||

| CS75B | 900 | Fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 2821×1880×2164 |

| Coarse | 159 | 175 | 13-38 | 59-163 | |||||

| CS110B | 1200 | Fine | 127 | 131 | 9-31 | 485 | 110 | 63-188 | 2821×1974×2651 |

| Medium | 156 | 156 | 13-38 | 100-200 | |||||

| Coarse | 178 | 191 | 19-51 | 141-308 | |||||

| CS160B | 1295 | Fine | 109 | 137 | 13-31 | 485 | 160 | 109-181 | 2800×2342×2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | |||||

| Coarse | 216 | 241 | 19-51 | 172-349 | |||||

| CS220B | 1650 | Fine | 188 | 209 | 16-38 | 485 | 220 | 181-327 | 3911×2870×3771 |

| Medium | 213 | 241 | 22-51 | 258-417 | |||||

| Coarse | 241 | 268 | 25-64 | 299-635 | |||||

| CS315B | 2134 | Fine | 253 | 278 | 19-38 | 435 | 315 | 381-726 | 4613×3251×4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | |||||

| Coarse | 334 | 369 | 31-64 | 789-1270 | |||||

A spring cone crusher is a compression-type crusher using a spring release system for overload protection. It’s commonly used for secondary and tertiary crushing of hard materials. Reliable crushing equipment.

Spring cone crushers are known for their robust design, reliable performance, and cost-effectiveness in crushing hard materials. Offers consistent crushing results.

Spring cone crushers are effective for crushing materials like granite, basalt, river stone, and other hard and abrasive rocks. Ideal for hard rock crushing.

The spring system allows the crushing chamber to open under overload conditions, preventing damage to the crusher components. Protects from overload damage.

Regular maintenance includes inspecting and replacing liners, checking the spring tension, and lubricating bearings. Ensure long-term crusher performance with proper upkeep.