全站搜索

Search the entire website

Search the entire website

Hammer crusher relies on the impact force to crush materials, which can crush various sized materials into uniform particles and then move to the next working step.

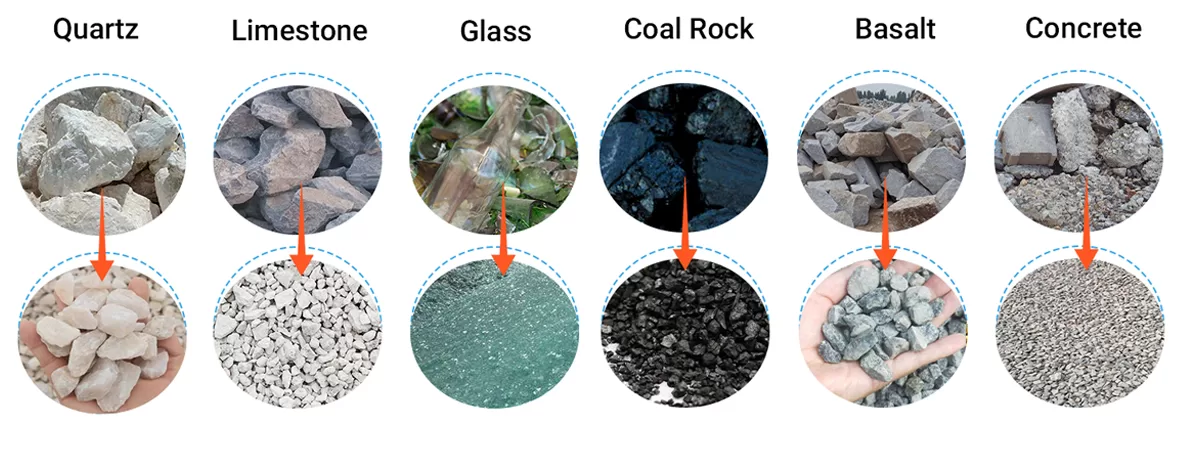

Hammer crusher is suitable for crushing various medium hardness and brittle materials, such as limestone, coal, salt, white ore, gypsum, alum, brick, tile, coal gangue, etc. The compressive strength of the crushed materials does not exceed 150MPa, and the water content is less than 15%. It is widely used in cement, coal preparation, power generation, building materials and compound fertilizer industries. It can crush raw materials of different sizes into uniform particles to facilitate the next process. It has reliable mechanical structure, high production efficiency and good applicability.

A Hammer Crusher, also known as a Hammer Mill, is a type of rock crusher that uses high-speed rotating hammers to shatter material. It is a very simple and efficient impact-style crusher. The main purpose of this machine is to achieve a large reduction ratio in one single stage. It excels at breaking soft and medium-hard materials.

The machine has a straightforward design. Inside a heavy steel box, a large rotor spins at high velocity. Heavy metal hammers are attached to this rotor. When you drop rocks into the machine, the spinning hammers strike them with extreme force. The rocks shatter instantly. A metal screen called a grate bar at the bottom controls the final size of the product. This simple mechanism makes the hammer crusher a low-cost and reliable choice for many operations.

Hammer crusher is suitable for crushing various medium hardness and brittle materials, such as limestone, coal, salt, white ore, gypsum, alum, brick, tile, coal gangue, etc. The compressive strength of the crushed materials does not exceed 150MPa, and the water content is less than 15%. It is widely used in cement, coal preparation, power generation, building materials and compound fertilizer industries. It can crush raw materials of different sizes into uniform particles to facilitate the next process. It has reliable mechanical structure, high production efficiency and good applicability.

Hammer crusher whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. The basic principle is straightforward. A hammer crusher is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size. The hammer crusher can be used as a primary, secondary, or tertiary crusher.

hammer crusher

Heavy type hammer crusher

Mobile Hammer Crusher

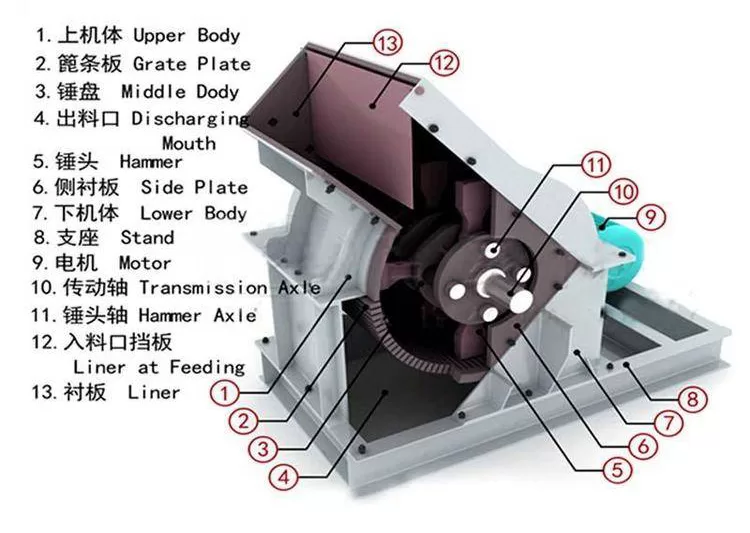

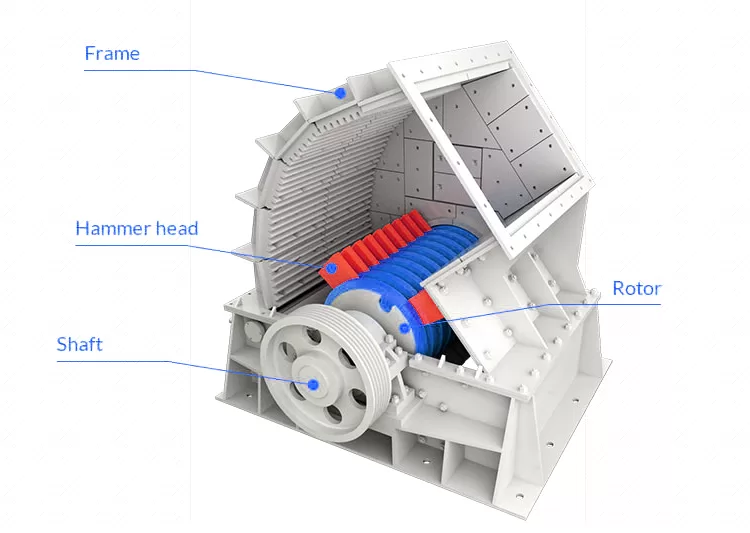

A hammer mill crusher is mainly composed of the frame, rotor, hammer head, main shaft, and other components.

In the hammer crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed products meeting the required size can be discharged by the outlet and become the final products; the large size products are brought back to the crushing area by the hammers for being re-crushed until they reach the required size.

A hammer crusher uses rotating hammers to impact and crush materials. Commonly used for crushing brittle materials like limestone, coal, and gypsum. Offers efficient material crushing.

Hammer crushers provide a high reduction ratio, simple structure, and are relatively inexpensive. They are efficient for crushing medium-hard and brittle materials. Cost-effective crushing solutions.

Hammer crushers effectively process materials like limestone, coal, gypsum, shale, and various other friable minerals. Versatile for different crushing needs.

Material is fed into the crusher and impacted by high-speed rotating hammers, then crushed against breaker plates. Achieve consistent particle reduction with impact crushing.

Regularly inspect and replace worn hammers, check the liners, and lubricate bearings. Proper maintenance ensures optimal performance and extends the crusher lifespan.