全站搜索

Search the entire website

Search the entire website

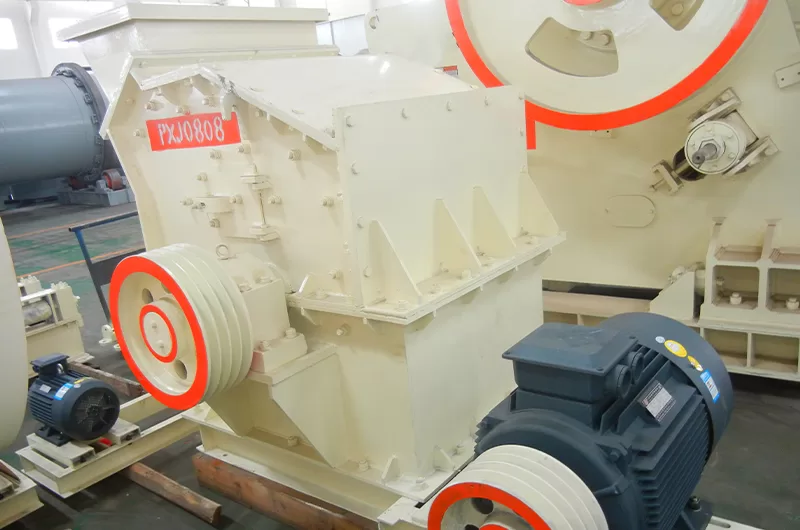

Fine crusher is also called tertiary crusher, which adopts the principle of “stone hit stone” to crush materials. It upgrades the traditional three crushing stages to the two crushing stages.

Fine jaw crusher is a robust and precise solution for pre-crushing a wide range of materials from middle hard to hard and brittle substances. Ideal for laboratories and processing companies, this stone crusher plant ensures fast and accurate sample processing. Its innovative design allows for easy maintenance with replaceable wear parts, minimizing downtime.

The fine crusher is mainly suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. The jaw crusher plant is used before the ball mill to increase the production efficiency of the ball mill by 50%.

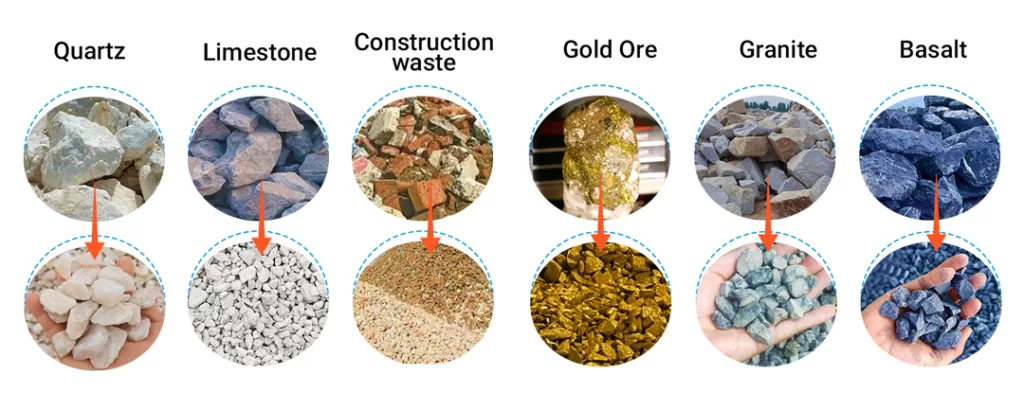

Fine jaw crusher is especially suitable for fine and medium crushing of materials with hardness below 9 such as quartz, feldspar, calcite, marble, ceramics, iron ore, copper ore, gangue, phosphate rock, granite, basalt, silicon carbide, corundum, insulation materials and other brittle materials.

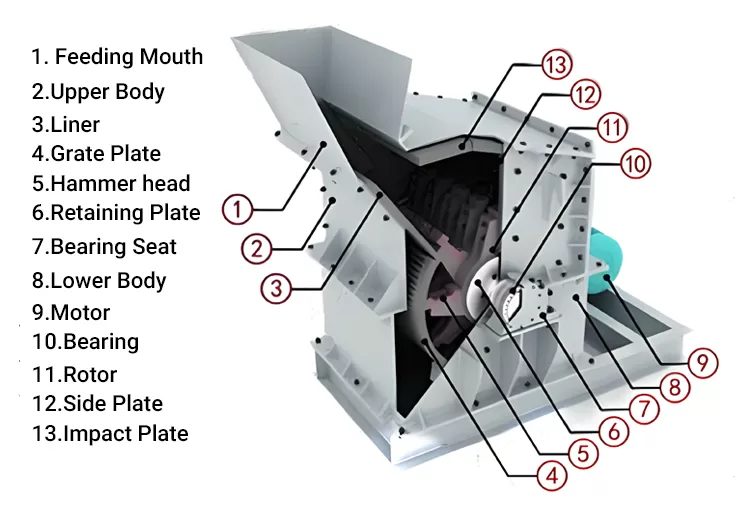

The fine jaw crusher is mainly composed of the rotary part, guard plate and box part.

Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part. The hammer head, whose width is larger than the hammer carrier and the wheel hub, is fixed on the hammer carrier. The wheel core is composed of several wheel hubs, which are fixed on the main shaft. The two ends of the main shaft are supported on the frame with rolling bearing seats.

The material is sent to the cavity from the inlet and falls on the high-speed rotating hammer head. The material is initially crushed between the hammer and the impact plate.

After the material is repeatedly hammered and impacted with high frequency, it forms a pile on the median septum, then falls on the material plate of the high-speed rotating lower rotor. Finally, it is thrown to the impact plate at high speed to be impacted, crushed and ground by the mobile plate hammer.

Therefore, the material undergoes multiple compound pulverization, scouring and grinding in the process of falling by its own weight to achieve an ultra-fine effect, and then is discharged through the discharging port.

| PXJ tertiary impact crusher | Rotorø×Width (mm) | |||||||

| Specification | 800×400 | 800×600 | 800×800 | 1010×1010 | 1200×1200 | 1400×1400 | 1600×1600 | 1800×1800 |

| Feed opening size(mm) | 400×185 | 500×250 | 550×300 | 1000×350 | 1200×450 | 1500 | 1600×550 | 1800×800 |

| Feeding size (mm) | <120 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

| Discharging size (mm) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Adjustable range of discharge opening (mm) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Cement Clinker(t/h) | 10-30 | 1040 | 20-45 | 25-55 | 35-90 | 50-150 | 85-210 | 125-270 |

| Limestone(t/h) | 18-45 | 23-55 | 28-65 | 35-75 | 45-110 | 50-150 | 95-260 | 140-310 |

| Power(kw) | 4P 37KW | 4P 45KW | 4P 45KW | 4P 55KW | 6P 110KW | 6P 160KW | 4P 250KW | 4P 315KW |

| Theoretical weight | 3.9 | 4.5 | 6 | 10.5 | 14.4 | 22 | 35 | 49.7 |

A fine crusher is a machine designed to reduce materials into very small sizes, often powders or fine granules. Suitable for minerals, aggregates, and chemical materials. Essential for particle size reduction.

Fine crushers produce a consistently fine output, require less maintenance than some other crushers, and are energy-efficient for fine crushing applications. High crushing efficiency assured.

Output particle sizes vary, but typically range from 0-5mm, depending on the crusher model and material. Achieve precise particle size control with adjustable settings.

Consider the material’s hardness, desired output size, and required production capacity. Consult with a crusher supplier to determine the best model for your needs. Optimise your crushing process.

Regular maintenance includes checking wear parts (hammers, liners), lubrication, and clearing any blockages. Consistent maintenance ensures reliable crusher performance and longevity.