全站搜索

Search the entire website

Search the entire website

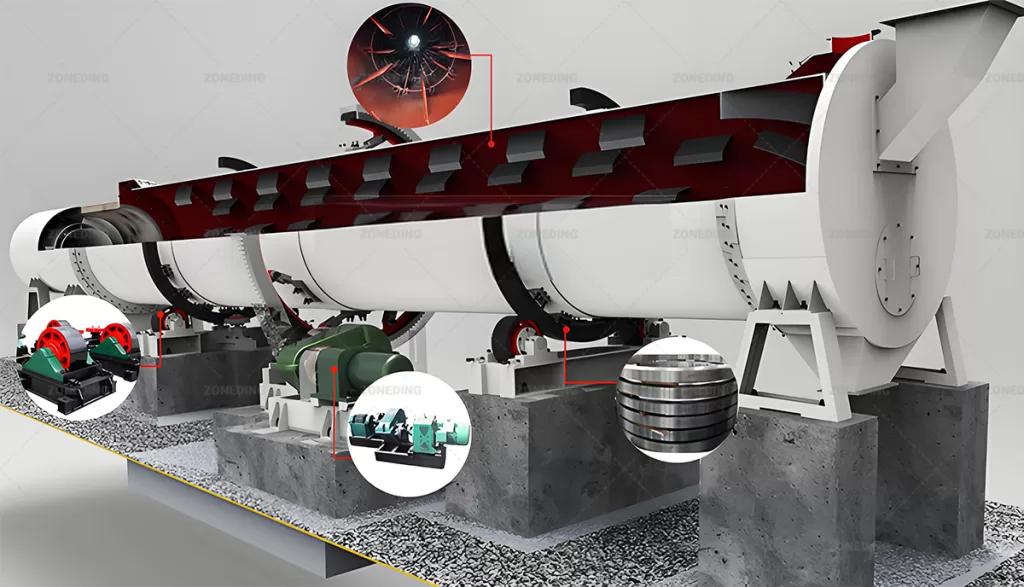

Desulfurization gypsum has high purity, large free water, fine particle size, and contains impurities such as unreacted calcium carbonate. The gypsum dryer adopts three-layer drum drying technology, which saves one-third of energy compared to traditional dryer and reduces production costs.

A gypsum dryer is a piece of industrial equipment specifically designed to reduce the moisture content (free water) of raw gypsum. It’s a crucial step in processing gypsum for various applications, most notably before it’s calcined to produce Plaster of Paris (stucco) used in wallboard manufacturing, or when preparing it as an additive for cement production.

Drying gypsum seems straightforward, but problems arise. Over-calcination ruins quality, and dust creates hazards. Selecting the correct dryer prevents these costly issues.Choosing a dryer designed specifically for gypsum is crucial. It ensures precise temperature control to prevent unwanted phase changes (calcination) and includes features to handle potential stickiness and manage fine dust effectively.

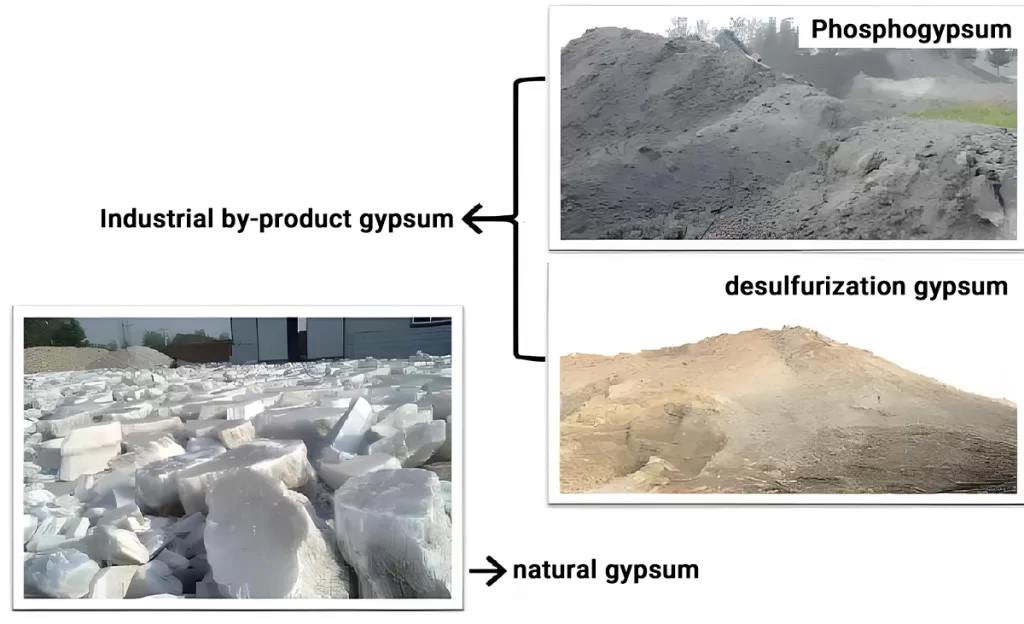

Handling gypsum involves more than just removing water. Different gypsum types have unique properties. Understanding these differences is key to selecting equipment that performs reliably and efficiently.

Gypsum (CaSO₄·2H₂O) loses crystal water at specific temperatures, changing into hemihydrate (CaSO₄·½H₂O) or anhydrite (CaSO₄). Drying aims to remove surface water only, while calcination requires precise temperature control to achieve the desired phase.

The primary goal of a gypsum dryer is to remove the free or surface moisture. This water is physically attached to the gypsum particles, often found in filter cake from processes like Flue Gas Desulfurization (FGD). Typically aim to reduce this moisture from maybe 10-20% down to less than 1%. This usually happens at temperatures below 120°C (248°F).

However, gypsum itself contains chemically bound water, called crystal water. Heating gypsum above certain temperatures (around 140-180°C or 284-356°F), it undergoes calcination. It loses 1.5 water molecules to become hemihydrate (Plaster of Paris), or all 2 water molecules to become anhydrite. If your goal is just drying (e.g., preparing gypsum for wallboard manufacturing where calcination happens later, or for cement production), exceeding these temperatures in the dryer is detrimental. It leads to unwanted calcination, creating a mix of dihydrate, hemihydrate, and possibly “dead-burned” anhydrite, which has poor setting properties. This results in inconsistent product quality and wasted energy. Therefore, precise temperature control in the dryer is essential to stay below calcination temperatures. Calcination requires different, specialized equipment like rotary kilns or kettle calciners.

| Water Type | Description | Removal Process | Target Temperature Range | Goal | Equipment Focus |

|---|---|---|---|---|---|

| Free Water | Surface moisture, mechanically held between particles. | Drying | < 120°C (248°F) | Remove moisture | Rotary Dryer |

| Crystal Water | Chemically bound within the CaSO₄·2H₂O structure. | Calcination | 140-180°C (284-356°F) for hemihydrate | Change phase | Rotary Kiln, Kettle |

Not all gypsum is the same. Natural rock gypsum behaves differently than synthetic gypsum from industrial processes. Knowing these differences helps select the right drying approach. Natural gypsum is often easier to handle. FGD gypsum is typically very fine, wet, and sticky. Phosphogypsum can contain impurities affecting drying and final product quality.

| Gypsum Type | Typical Feed State | Key Drying Challenges | Primary Considerations |

|---|---|---|---|

| Natural Gypsum | Crushed rock | Control temperature to avoid calcination. | Flowability generally good. |

| FGD Gypsum | Wet filter cake | High stickiness, high moisture, potential corrosivity (Cl⁻). | Anti-sticking design, material selection. |

| Phosphogypsum | Wet filter cake | High moisture, potential impurities (P₂O₅, others), acidity. | Impurity impact, potential corrosivity. |

Many dryer types exist, each with strengths and weaknesses. Choosing the wrong one means inefficiency or poor product. The best choice depends on specific gypsum and goals.

Rotary dryers are the most common and versatile for drying various gypsum types, especially for large capacities. Air stream (flash) dryers can work for fine materials if retention time is sufficient, but struggle with sticky FGD gypsum.

| Dryer Type | Suitability for Gypsum Drying | Advantages | Disadvantages |

|---|---|---|---|

| Rotary Dryer | High (especially with modifications) | Versatile, handles feed variations, robust. | Needs anti-sticking for FGD, larger footprint. |

| Air/Flash Dryer | Medium (for fine, non-sticky) | Fast drying, compact. | Struggles with sticky feed, short residence time, dust load. |

| Fluidized Bed | Medium (potential for good heat transfer) | Good mixing, efficient heat transfer. | Potential issues with stickiness, requires uniform feed. |

| Kettle/Calciner | Not for drying (for calcination) | Produces specific phases (hemihydrate). | Not designed for efficient free water removal. |

Heating gypsum too much or for too long changes its structure permanently. This “over-burning” ruins its ability to set properly. Precise control is needed for quality.

Control requires careful management of the heat source output (burner/furnace) and airflow, coupled with monitoring the material temperature, especially near the discharge. Maintaining outlet temperatures below the critical calcination point (around 120°C) is key.

Avoiding unwanted calcination (“over-burning” or “dead-burning”) during the drying stage is primarily about temperature and time control. In a direct-heat rotary dryer, the main control inputs are the temperature of the hot gas entering the dryer and the volume of that gas (airflow). The material’s residence time is controlled by the dryer’s rotation speed, slope, and internal dam rings or lifter design.

To prevent over-heating, ensure the material temperature is important, particularly as it nears the discharge end, stays below the point where significant crystal water loss begins (roughly 120-130°C for drying). This requires:

Modern control systems (PLCs) can use feedback from material temperature sensors to automatically adjust the heat input, ensuring the gypsum is dried effectively without exceeding the critical threshold for unwanted phase changes.

| Control Element | Method | Purpose | Key Point |

|---|---|---|---|

| Heat Source Output | Adjust burner firing rate / furnace output. | Control overall energy input to the dryer. | Match energy to evaporation load. |

| Airflow Rate | Adjust fan speed (VFD). | Control heat delivery and moisture removal rate. | Balance efficiency and temp. |

| Material Temp Sensors | Thermocouples placed within material bed. | Provide direct feedback on product temperature. | Crucial for preventing overshoot. |

| Retention Time | Adjust drum speed / slope. | Control how long material is exposed to heat. | Ensure sufficient drying time. |

| Feed Rate Control | Stable feeding system. | Maintain consistent load on the dryer for stable temps. | Avoid fluctuations. |

FGD Gypsum arrives very wet and clumps together easily. Standard dryers clog quickly with this material. Specific design features are essential for reliable operation.

Dryers for FGD gypsum require specialized internal lifting flights (e.g., combination or chain types), potentially back-mixing systems, optimized feed end design, and sometimes specific materials to combat stickiness and potential corrosion.

Handling the challenging properties of FGD gypsum requires specific adaptations in the rotary dryer design. As highlighted before, its high moisture content and fine particle size make it extremely sticky. To prevent severe buildup on the shell and lifters, which kills efficiency and causes blockages, we implement several strategies at ZONEDING:

| Feature | Description | Benefit |

|---|---|---|

| Specialized Lifters | Combination flights, channel flights, chain curtains/systems. | Prevent sticking, break clumps, enhance heat transfer. |

| Back-Mixing System | Controlled recycle of dry product to mix with wet feed. | Reduces feed stickiness, improves flowability. |

| Optimized Feed End | Smooth, non-restrictive entry design. | Minimizes initial buildup. |

| Material Selection | Use of stainless steel or alloys in critical areas. | Resists corrosion from chlorides or acidity. |

| Operational Tuning | Adjusting drum speed/slope for optimal material movement. | Helps move material quickly through sticky zones. |

Drying uses a lot of energy, mainly fuel for heating. High energy use means high operating costs. Smart choices in design and operation can save significant money.

Reduce costs by optimizing the heat source, ensuring good insulation and sealing, controlling airflow effectively, minimizing heat loss, and potentially utilizing waste heat if available. Proper maintenance also prevents efficiency drops.

Energy, primarily fuel for the heat source, is typically the largest operating expense for a gypsum dryer. Reducing this consumption directly improves profitability. Several strategies contribute to lower energy use and operating costs:

| Cost Reduction Strategy | Detail | Impact |

|---|---|---|

| Fuel Choice/Waste Heat | Select lowest cost fuel; utilize available waste heat sources. | Directly reduces primary energy cost. |

| Combustion Efficiency | Ensure complete fuel burning with proper air/fuel ratio. | Maximizes heat generated per unit of fuel. |

| Insulation | Proper insulation on dryer shell and ducts. | Minimizes radiative and convective heat loss. |

| Sealing | High-quality, well-maintained feed/discharge seals. | Prevents energy loss from air leaks. |

| Parameter Optimization | Run at optimal temperature, airflow, and retention time. | Avoids wasting energy on excessive heating or air movement. |

| Regular Maintenance | Keep internals clean, seals effective, components lubricated. | Maintains design efficiency, prevents gradual performance degradation. |

| Feed Dewatering | Reduce incoming moisture mechanically where possible. | Less water to evaporate means less thermal energy required. |

Drying gypsum creates fine dust that easily becomes airborne. This is not just messy; it’s a safety, environmental, and economic issue. Effective dust control is non-negotiable.

It is critically important. A high-efficiency dust collector, typically a baghouse, is essential to meet environmental regulations, prevent product loss, ensure worker safety, and maintain reliable dryer operation through proper system airflow.

Gypsum dust generated during drying is fine and pervasive. Letting it escape into the atmosphere is unacceptable due to environmental regulations and potential health concerns for workers. Furthermore, this dust is valuable product; losing it reduces your yield. Effective dust collection is therefore essential, not optional.

The standard solution for the fine dust from gypsum dryers is a baghouse (fabric filter). Cyclones alone are rarely sufficient for the fine particles involved. Key factors for selecting and operating a baghouse for gypsum dust include:

| Aspect | Importance | Common Solution / Consideration |

|---|---|---|

| Emission Control | Meet environmental regulations, avoid fines/shutdowns. | High-efficiency baghouse filter. |

| Product Recovery | Dust collected is valuable product. | Return collected dust to the product stream (if appropriate). |

| Worker Safety | Reduce airborne dust exposure. | Enclosed system, effective collection. |

| System Operation | Proper airflow is needed for drying efficiency. | Correctly sized fan and collector, maintain low pressure drop. |

| Equipment Choice | Needs high efficiency for fine particles. | Baghouse typically required; cyclone as pre-collector optional. |

| Filter Bag Selection | Must withstand temperature, potential corrosion, fine dust. | Appropriate material, possibly specialized coatings. |

| System Sealing | Prevent dust escaping from flanges, access doors, dryer ends. | Quality gaskets, well-maintained seals on dryer/ducts. |

Investing in a large industrial dryer requires careful specification. Focusing on the right technical details ensures you get a machine that meets your needs efficiently and reliably.

Key parameters include required throughput, feed and target moisture levels, gypsum type (natural/FGD/phospho) and its properties (stickiness, impurities), available heat source, required product temperature (avoiding calcination), and emission limits.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

When you are ready to purchase a gypsum dryer, providing detailed information to the manufacturer is crucial for getting the right equipment.

At ZONEDING, several key technical parameters is needed to design and quote accurately:

Providing this detailed information, ZONEDING can engineer a dryer (likely a customized rotary dryer) that meets your specific throughput, product quality, and operational requirements efficiently and reliably.

| Parameter | Importance | Information Needed |

|---|---|---|

| Capacity | Determines dryer size. | Tons per hour (wet feed or dry product basis). |

| Moisture Levels | Dictates energy needs and drying time. | Feed % (avg/max), Target final %. |

| Gypsum Type & Analysis | Influences design (stickiness, corrosion), material selection. | Natural/FGD/Phospho; Particle size, Stickiness index, Impurities (Cl⁻, P₂O₅). |

| Max Product Temp | Critical to prevent unwanted calcination. | Maximum allowable discharge material temperature (°C or °F). |

| Heat Source Details | Affects burner/furnace design, operating cost, potential contamination. | Fuel type, availability, cost, composition (if waste heat). |

| Emission Regulations | Dictates dust collection system requirements. | Required outlet dust concentration (e.g., mg/Nm³). |

| Operating Environment | Influences structural design, fan sizing. | Site layout, altitude, ambient conditions. |

Buying a dryer is just the start. Ongoing support from the supplier is vital for long-term success. Evaluate their experience with your specific gypsum type, engineering support during design/installation, availability of spare parts, responsiveness to issues, operator training programs, and warranty terms. Look for a partner, not just a seller.

Choosing the right supplier for your gypsum dryer involves more than just comparing technical specifications and price. The quality of their support and service is crucial for smooth installation, commissioning, and long-term reliable operation.

ZONEDING MACHINE, as a reliable long-term partner, with comprehensive product line, customization capabilities, factory-direct model, and global experience (exporting to 120+ countries) and full-service support, can ensure you receive not just equipment, but a complete drying solution.

A gypsum dryer removes excess moisture from gypsum, a mineral used in construction materials like drywall and plaster. Drying is a critical step to ensure the gypsum sets correctly and has the required strength. Ensures product quality.

Drying gypsum is essential to control its hydration, preventing premature setting, improving its workability, and ensuring the final product meets industry standards for strength and durability. Promotes material stability.

Common gypsum dryer types include rotary dryers, fluid bed dryers, and flash dryers, selected based on throughput needs, particle size, and energy efficiency considerations for the gypsum product. Supports efficient processing.

Gypsum dryers use heated air to evaporate moisture from the gypsum particles as they pass through the dryer. This process reduces the moisture content to the desired level for subsequent processing. Improves energy optimization.