全站搜索

Search the entire website

Search the entire website

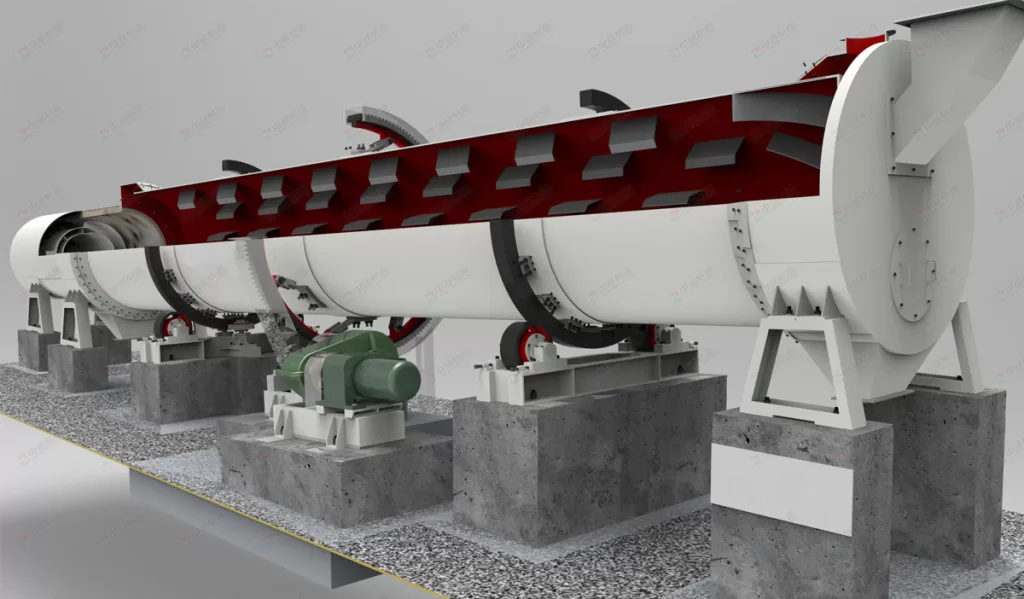

The Slurry & Sludge Dryer is a rotary dryer that specializes in drying various slurries, including slime, which can be called a slime dryer. In addition, it is used for the drying of sludge, metallic and non-metallic ores, clays in the cement industry, etc. The slurry dryer uses a unique scattering device that disperses the bonded slurry and enters the drying process.

A slurry dryer is industrial equipment specifically designed to remove liquid (usually water) from a pumpable mixture of fine solid particles suspended in that liquid. It transforms the wet slurry into a dried solid product like powder, granules, or cake.

Slurries come in many forms across industries – mineral concentrates, coal fines, tailings, clays, chemical precipitates, wastewater sludge. Drying them is often essential for further use or disposal. As ZONEDING, we build dryers to handle these challenging materials.

Slurry drying is vital to reduce transport costs, meet downstream process requirements, improve handling and storage, recover valuable solids, meet product specifications, or enable safe disposal.

There are compelling reasons across various industries to remove water from slurries:

At ZONEDING, we understand these drivers and help industries select the right drying solution for their specific slurry and objectives.

A rotary slurry (sludge) dryer tumbles the sludge inside a gently inclined, rotating drum while hot gas flows through. Internal lifters continuously lift and shower the sludge through the hot gas stream, promoting heat transfer and water evaporation. Special designs combat stickiness.

Rotary dryers are a common choice for municipal and industrial sludges due to their robustness and capacity. The process involves several key actions:

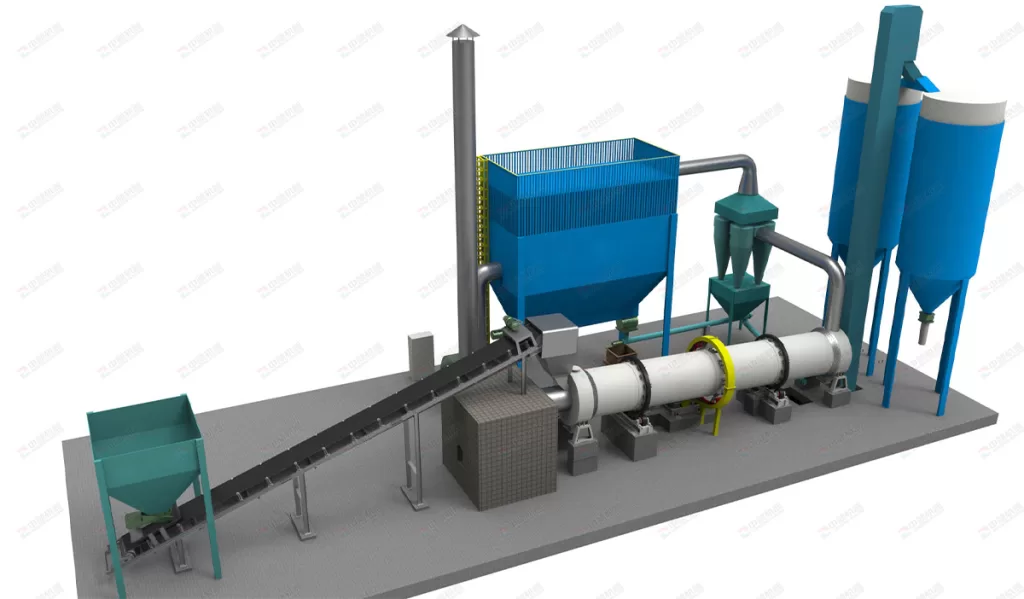

A slurry dryer doesn’t operate in isolation. It needs supporting equipment to feed it, heat it, handle the exhaust, and control the process. Understanding the full system is vital.

A complete system typically requires: a slurry feed pump (appropriate type for slurry ), possibly a feed tank/mixer , the heat source (burner/steam), the dryer itself, ducting, dust collector, exhaust fan, product discharge system, and controls.

A functional slurry drying plant involves several critical pieces of auxiliary equipment working together:

ZONEDING provides complete, engineered slurry drying systems, ensuring all necessary auxiliary components are correctly selected, sized, and integrated for reliable and efficient operation.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

A slurry & sludge dryer removes moisture from slurries and sludges, which are semi-solid mixtures containing high water content. This reduces volume, making the material easier to handle and dispose of, and potentially enabling reuse. Facilitates waste reduction.

Drying slurry & sludge reduces landfill volume, lowers transportation costs, and can create valuable byproducts like fertilizer or biofuel. It supports sustainable waste management practices and resource recovery. Supports circular economy.

Slurry & sludge dryer options include rotary dryers, belt dryers, disc dryers, and solar dryers, each suited to different sludge characteristics, throughput rates, and energy source availability. Offers flexible solutions.

Slurry & sludge dryers utilize heat transfer mechanisms (conduction, convection, or radiation) to evaporate the water content, resulting in a drier, more manageable solid. The specific method varies by dryer type. Ensures effective dehydration.