全站搜索

Search the entire website

Search the entire website

A successful talc grinding plant design is a manufacturing strategy dictated by your target market. The design must scale in complexity and investment—from simple ball mills for basic fillers to advanced jet mills for high-purity, micronized products.

Before designing a plant, you must understand what you are producing. Talc is not just “soft rock”; it is a hydrous magnesium silicate with a unique combination of properties.

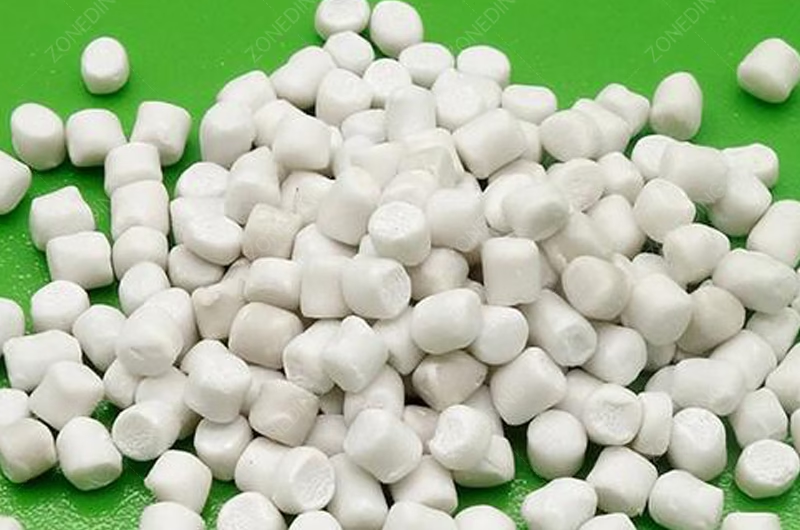

Talc is an industrial mineral prized for its softness, lamellar (platy) structure, chemical inertness, and whiteness. Its main applications are in plastics, paints, paper, ceramics, rubber, and cosmetics, where it acts as a functional filler and additive.

Each industry leverages a different property of talc, and your plant design must be able to deliver that specific property consistently.

Understanding the “why” behind each application is crucial for your design choices.

| Application | Key Property Leveraged | Why It’s Important for the Customer |

|---|---|---|

| Plastics (Automotive) | Lamellar (platy) structure | Provides stiffness, dimensional stability, and impact resistance. |

| Paints & Coatings | Particle size & whiteness | Acts as an extender, controls gloss, improves paint durability. |

| Paper Manufacturing | Softness & whiteness | Reduces friction on paper-making machinery, improves printability. |

| Ceramics | Chemical composition | Acts as a flux, lowering firing temperatures and improving thermal shock resistance. |

| Cosmetics & Pharma | Purity & softness | Serves as a safe, soft, and absorbent base for powders and tablets. |

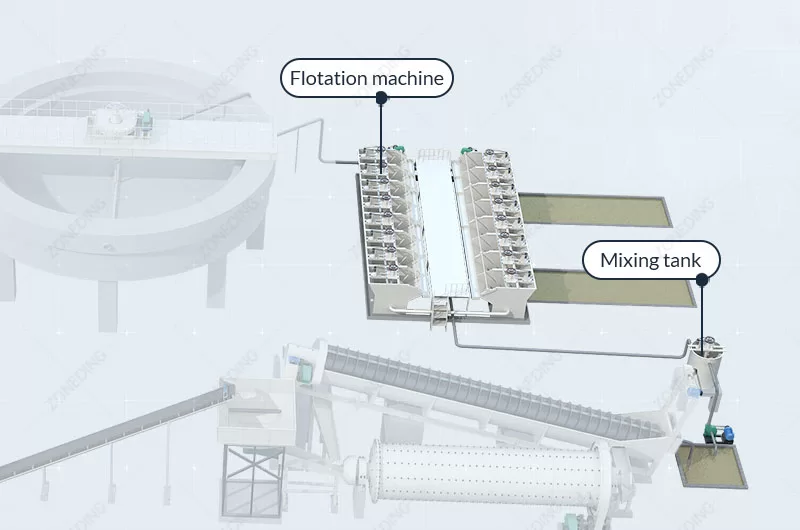

Your raw talc ore is never 100% pure. It contains impurities like magnesite, dolomite, and carbon that reduce its whiteness and value. A flotation circuit is not a cost; it is an investment in quality.

A talc flotation process leverages the mineral’s natural hydrophobicity (water-repelling nature). In a flotation machine, talc particles attach to air bubbles and float to the surface, separating them from water-attracting impurities, thus achieving significant whiteness improvement.

This is the first and most critical step in producing high-grade talc. Without it, you are locked out of the plastics, paint, and cosmetics markets.

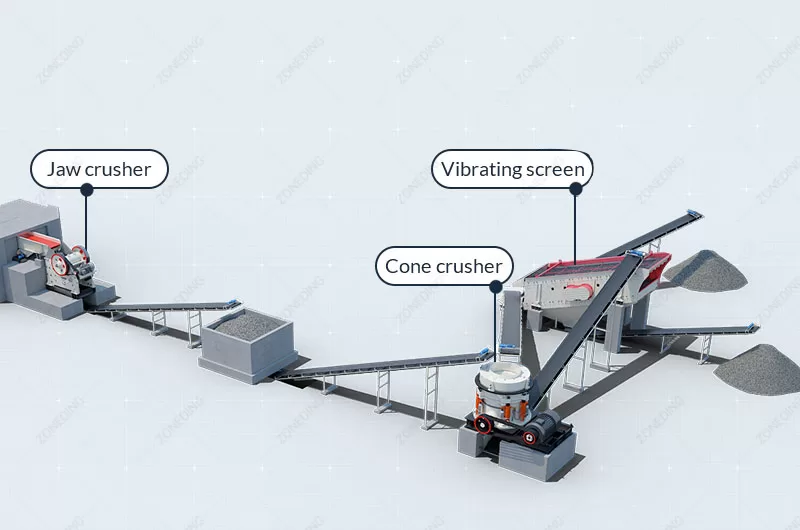

The design is a multi-step process:

This is the entry-level market for talc powder, often used in ceramics, roofing materials, and lower-grade fillers. The key design goal here is minimizing capital investment.

For a low-cost talc powder production line producing 325 mesh talc powder, the classic combination of a ball mill and classifier in a closed circuit is the most reliable and budget-friendly design. It is a proven, robust technology for coarse grinding.

While not the most energy-efficient, its simplicity and low upfront cost make it an attractive starting point.

The system works in a continuous loop:

This is the largest market segment, including high-quality paint grade talc and plastic grade talc. Here, efficiency and precise particle size control are more important than the lowest possible capital cost.

For ultrafine talc grinding in the 800-2500 mesh range, a vertical roller mill is often the preferred choice due to its high energy efficiency and integrated drying and classifying capabilities. An advanced ball mill with a high-performance turbo classifier is also a strong competitor.

This is a key investment cost analysis decision.

Your choice depends on your specific needs for efficiency, space, and maintenance.

| Feature | Vertical Roller Mill (VRM) | Advanced Ball Mill + Turbo Classifier |

|---|---|---|

| Energy Efficiency | Excellent. Grinds, dries, and classifies in one machine. | Good, but generally less efficient than a VRM. |

| Footprint | Smaller, as it is a vertical unit. | Larger, as it requires two separate machines. |

| Fineness Control | Very good, with an integrated high-efficiency classifier. | Excellent, a high-performance turbo classifier gives precise cuts. |

| Maintenance | More complex, requires specialized technicians. | Simpler, more familiar technology for most maintenance teams. |

| Capital Cost | Higher initial investment. | Lower initial investment for the same capacity. |

| Capital Cost | Higher initial investment. | Lower initial investment for the same capacity. |

This is the premium market. We are talking about high-performance plastics, high-end cosmetics, and specialty applications where particle size is measured in single-digit microns.

When your target market demands extreme fineness (>2500 mesh or <5 microns) and absolute purity with zero metal contamination, you must invest in a jet mill. This technology uses particle-on-particle attrition, preserving the talc’s valuable platy structure.

A jet mill is not just a grinder; it is a tool for manufacturing high-performance materials.

Producing a pure, fine powder is only half the battle. To unlock the highest profit margins, you must make your product perform better in your customer’s application. That requires surface modification.

A surface coating machine is integrated after the grinding circuit. It coats individual talc particles with a chemical (like stearic acid or silane), transforming them from hydrophilic (water-loving) to hydrophobic (water-repelling), dramatically improving dispersion in polymers and plastics.

This process adds significant value and turns your talc from a simple filler into a high-performance additive. It is a direct route to higher profitability.

A complete talc micronizing plant is more than just a mill. It is an integrated system where every component must work together seamlessly. A poor plant layout design will create bottlenecks and reduce efficiency.

A complete talc processing technology process flowsheet includes a multi-stage crushing unit, raw material silos, the chosen grinding/classifying system (ball, vertical, or jet mill), a product collection system (cyclone + baghouse), finished product silos with fluidization, and an automated bagging machine.

Each stage must be carefully planned.

Your talc plant’s design is a direct reflection of your business strategy. By starting with a clear market target and selecting the appropriate purification, grinding, and surface modification technologies, you can build a facility that is not just a factory, but a source of high-value, engineered materials.