全站搜索

Search the entire website

Search the entire website

The Raymond Mill, or Pendulum Grinder, remains a highly relevant and profitable investment for a specific range of applications. Its value lies in its unbeatable combination of low initial cost, operational simplicity, and robustness, especially for producing powders in the 100-400 mesh range.

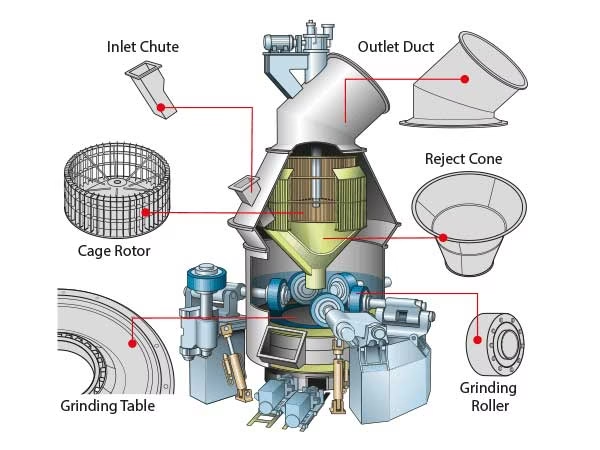

Many people see a Raymond Mill as a simple grinder. That is a critical misunderstanding. It is an air-swept classification system that uses a grinding zone to produce particles. Its genius is in its simplicity and the synergy of its components.

The Raymond Mill’s working principle uses centrifugal force. As a central spider rotates, rollers swing outwards, pressing against a stationary grinding ring. Plows scoop material into the path of the rollers, and a constant airflow lifts the pulverized powder up to an internal classifier, which separates the fine product from the coarse rejects.

Its enduring popularity comes down to a few core truths:

This is the most common decision a modern investor faces. Both are excellent machines, but they are designed for different economic and operational priorities. Choosing the wrong one can permanently handicap your plant’s profitability.

A Raymond Mill is the ideal choice for projects with limited initial capital, producing powders up to 400 mesh. A Vertical Roller Mill is a better investment for large-scale operations requiring higher energy efficiency, a smaller footprint, and production of finer powders.

I have helped many clients make this choice. Here is the decision matrix I use:

| Feature | Raymond Mill | Vertical Roller Mill (VRM) |

|---|---|---|

| Initial Investment | Lower. The primary advantage. | Higher. Can be 1.5x to 2.5x the cost. |

| Energy Efficiency | Good. | Excellent. Can save 20-30% in power consumption. |

| Fineness Range | Good (100 – 400 mesh). | Excellent. Can efficiently produce finer powders (up to 800+ mesh). |

| Footprint | Larger, horizontal layout. | Smaller, vertical design saves space. |

| Maintenance | Simpler. Easier to access and replace wear parts. | More complex, requires more specialized skills. |

| Single Unit Capacity | Moderate (up to ~50 tph). | Very High. Can exceed 100 tph in a single unit. |

Choosing the right size is critical. An undersized mill will never meet your production targets, while an oversized mill is a waste of capital and energy. The model numbers seem cryptic, but they are actually quite simple.

The Raymond Mill model (e.g., 3R, 4R, 5R) indicates the number of rollers. The full Raymond Mill specifications, like 5R 4119, further define the ring diameter. More rollers and a larger ring diameter directly translate to higher capacity.

Here is a general guide to help you match a model to your needs for a standard material like limestone, ground to 325 mesh:

| Model Series | Number of Rollers | Typical Capacity (tph) | Common Applications |

|---|---|---|---|

| 3R Series | 3 Rollers | 1 – 5 | Small-scale production, laboratories, specialized products. |

| 4R Series | 4 Rollers | 3 – 12 | Medium-sized plants, common for barite grinding. |

| 5R Series | 5 Rollers | 8 – 25 | High-volume industrial mineral powder processing. |

| 6R Series | 6 Rollers | 15 – 45+ | Large-scale limestone grinding, power plant desulfurization. |

A smart investor looks beyond the purchase price to the Total Cost of Ownership (TCO). For a Raymond Mill, this means understanding your spending on power and wear parts.

The two main operational costs for a Raymond Mill are electricity (power consumption** for the main motor and fan) and the regular replacement of wear parts, primarily the grinding roller and ring . The cost of these parts is directly related to the abrasiveness of the material you are grinding.

Let’s break it down:

This is a common question driven by the demand for higher-value products. It is crucial to understand the mill’s technical limits to avoid disappointment.

The practical fineness limit for a standard Raymond Mill is around 400-500 mesh (about 25-30 microns). While it can produce small amounts of finer particles, it is not an efficient machine for producing true ultrafine powder (over 800 mesh). The limitation is in its air classification system.

The classifier (or separator) at the top of the mill spins to create a centrifugal field. Air flowing inwards carries the fine particles, while the centrifugal force throws coarser particles back into the grinding zone.

Many operators struggle with performance issues. In my experience, 90% of these problems are not due to the mill itself but to incorrect operation, especially a misunderstanding of the airflow.

The most common causes for low output or inconsistent fineness in a Raymond Mill are improper airflow settings, worn-out wear parts (especially plows), inconsistent feed size, or excessive moisture in the raw material.

Here are the solutions I provide most often:

| Problem | Likely Cause | Solution |

|---|---|---|

| Low Production | Incorrect airflow (too low or too high); Worn plows. | Calibrate the main fan damper to achieve the correct air velocity. Check and replace worn plow tips. |

| Coarse/Uneven Powder | Classifier speed is too high; Worn classifier blades. | Reduce the classifier speed (requires a VFD for best control). Inspect blades for wear or blockages. |

| High Vibration | Oversized feed material; Worn rollers/ring causing bouncing. | Ensure the feed is consistently below 25mm. Check wear parts for flat spots or chunking. |

| System Clogging | High moisture in feed condensing in the system. | Pre-heat the entire mill system with hot air before introducing feed. Ensure raw material is as dry as possible. |

The Raymond Mill is not a universal solution, but for its target materials, it is often the most cost-effective one.

The Raymond Mill excels at grinding non-flammable, non-explosive, brittle materials with a Mohs hardness below 7. It is the dominant grinding equipment in industries producing powders for construction, chemicals, and fillers.

Main application materials:

This is often the first question an investor asks. While the price varies by size and manufacturer, it is important to understand what is included.

The Raymond mill price for a complete system, including the main mill, motor, fan, cyclone, baghouse, and electrical controls, can range from $30,000 for a small 3R model to over $200,000 for a large 6R or 7R model. The final price depends on the model, configuration, and level of automation.

As a factory-direct manufacturer, we provide a complete, engineered solution.

The Raymond Mill is a fantastic investment when applied correctly. It offers a reliable, cost-effective solution for producing mineral powders in the most common fineness ranges. Understanding its capabilities, limitations, and operational nuances is the key to turning this classic machine into a modern, profitable production asset.

A Centrifugal Concentrator / Mining Centrifuge is a machine that uses centrifugal force to separate materials of different densities, commonly used in mineral processing.

Mining Centrifuges effectively process gold, silver, platinum, tantalum, and other valuable heavy minerals from ore and tailings.

Centrifugal Concentrators provide high recovery rates, low operating costs, and environmentally friendly mineral processing compared to traditional methods.

A Mining Centrifuge uses a rotating bowl or cone to create centrifugal force, separating heavier minerals from lighter materials based on density.

Consider feed rate, particle size, recovery rate, capacity, and maintenance requirements when selecting a Mining Centrifuge for your operation.