全站搜索

Search the entire website

Search the entire website

A successful bauxite grinding plant design is a bespoke engineering solution that balances ore characteristics (mineralogy and hardness) with a target particle size distribution (PSD). The goal is to optimize the subsequent chemical digestion process. For the Bayer process, this is almost universally achieved through a wet grinding circuit, typically employing a ball mill for bauxite in a closed loop with hydrocyclones.

The primary goal of grinding is to liberate the alumina-bearing minerals and create sufficient surface area for the hot caustic liquor to react with them efficiently.

A finer grind increases the rate and overall percentage of alumina dissolution in the digesters. However, this comes at an exponentially higher cost in terms of electrical energy and grinding media consumption. The optimal bauxite grinding plant design targets a specific particle size distribution (PSD) that represents the most economic balance between these competing factors.

This balance is the single most important parameter in the plant’s design.

This is the most fundamental process decision. The nature of the downstream Bayer process heavily influences the choice.

Wet grinding is the standard and overwhelmingly preferred method for bauxite processing. Since the Bayer process is an aqueous chemical process, wet grinding delivers the product directly as a pumpable slurry. A dry grinding circuit would require a complex, energy-intensive drying stage followed by a re-slurrying stage, adding unnecessary capital and operational costs.

The choice is almost always clear.

| Feature | Wet Grinding Circuit | Dry Grinding Circuit |

|---|---|---|

| Process Logic | Aligns directly with the wet Bayer process. | Adds unnecessary drying and re-pulping steps. |

| Capital Cost | Lower. No large dryers or complex powder handling systems needed. | Higher. Requires large rotary dryers, extensive dust collection, and powder silos. |

| Energy Consumption | Lower. Avoids the high thermal energy demand of drying. | Significantly higher due to fuel for drying. |

| Dust Control | Inherently dust-free operation. | A major design challenge requiring extensive baghouse systems. |

| Product | A precisely controlled slurry, ready for pumping. | A dry powder that must be carefully mixed back into a slurry. |

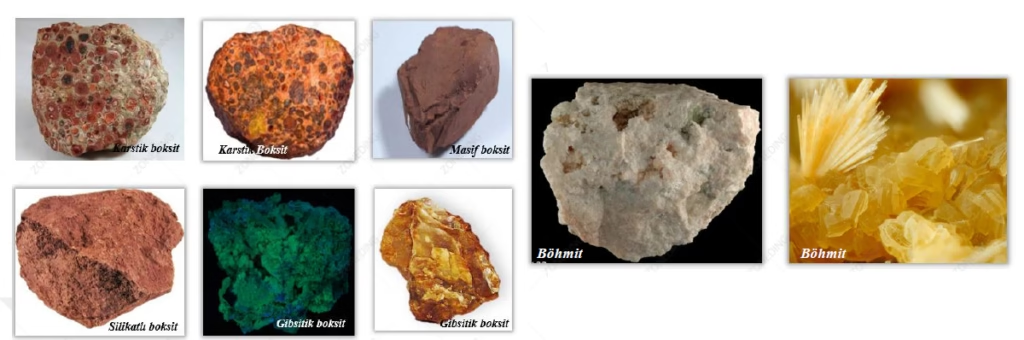

Bauxite is not a single mineral. Its composition dictates the required grinding energy and, therefore, the size and power of the grinding mill.

Hard, monohydrate bauxites (primarily Diaspore and Böhmite) require significantly more grinding energy than soft, trihydrate bauxites (Gibbsite). A plant designed for soft gibbsitic ore will fail to achieve the required throughput and fineness if fed hard diaspore. The mill selection must be based on the hardest ore type expected during the life of the mine.

This requires detailed ore characterization.

While other mills exist, the overflow ball mill has remained the industry standard for bauxite wet grinding for decades.

The ball mill for bauxite is the preferred technology due to its robustness, reliability, and high efficiency in handling abrasive slurries. Its simple design and proven performance in continuous, heavy-duty operation make it the most cost-effective solution for the large-scale grinding required by alumina refineries.

Its simplicity is its greatest strength. A ball mill is a large rotating cylinder partially filled with steel balls. As the mill rotates, the balls are lifted and then cascade down, creating a powerful grinding action through impact and attrition that crushes and grinds the ore particles. It is perfectly suited for producing the fine slurries needed for the Bayer process.

Producing a slurry with a consistent particle size is impossible with a mill alone. A classification system is essential.

A closed grinding circuit combines a ball mill with a hydrocyclone. The hydrocyclone separates the mill discharge into fine and coarse particles. The fine product (overflow) proceeds to the Bayer process, while the coarse particles (underflow) are recycled back to the mill for further grinding. This ensures that all particles reach the target fineness without over-grinding, maximizing efficiency.

This loop is the heart of process control. The performance of the hydrocyclone—controlled by its geometry, apex and vortex finder size, and feed pressure—directly determines the final particle size of the product sent to the refinery.

The long-term profitability of the plant is often determined by the details of its consumable components.

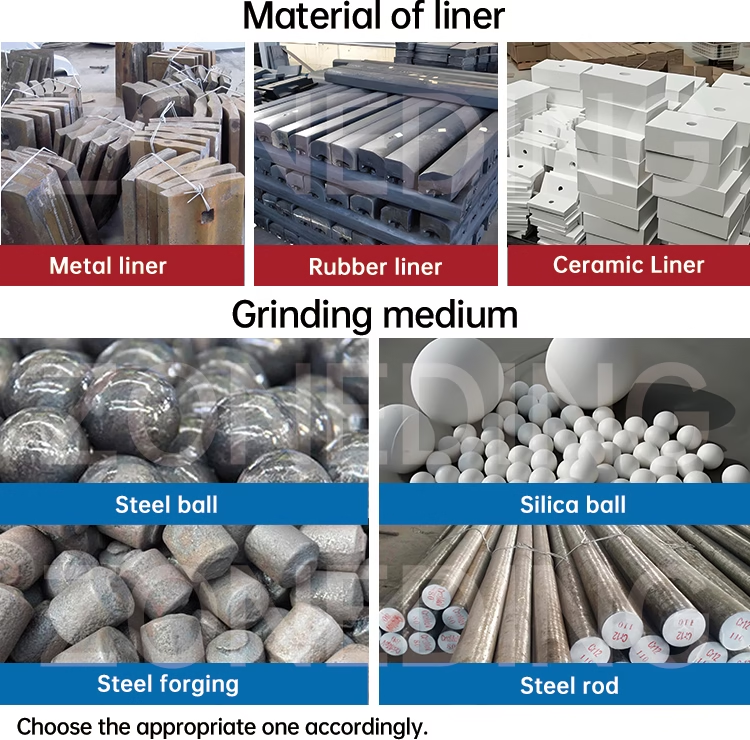

The selection of mill liners and grinding media (steel balls) has a major impact on operating cost. High-quality, wear-resistant materials reduce the consumption rate of these components, leading to lower costs and less downtime for replacement. The liner profile is also engineered to optimize the grinding action, improving energy efficiency.

These are not commodities; they are engineered components.

A successful design integrates the process requirements with practical operational needs.

Designing a bauxite grinding plant requires a comprehensive approach, starting with a detailed process flowsheet. The plant layout must then consider material handling of sticky ore, robust slurry pumping systems, safe access for maintenance, and automated process control loops for slurry density and particle size.

A holistic view is essential. The equipment itself is part of a larger system. An initial feasibility study will model the mass and water balance, determine equipment sizes, and estimate the capital and operating costs. A typical grinding plant equipment package can represent an investment from $1 million to over $10 million, depending on capacity and ore complexity.

The design of a bauxite grinding plant is the foundational engineering step for any successful alumina production facility. It is a highly specialized task that demands a deep understanding of the ore’s mineralogy and a clear focus on the economic objectives of the downstream Bayer process. A well-designed plant is a robust, efficient, and profitable asset; a poorly designed one is a permanent liability for the entire refinery.