全站搜索

Search the entire website

Search the entire website

Based on their oxidation rates, copper ores are categorized as sulfide ore (less than 10%), oxidized ore (greater than 30%), or mixed ore (10%-30%). The primary beneficiation method for copper ore is flotation, with gravity separation also used in some cases. Generally, copper sulfide ores and easily beneficiated mixed copper ores are treated by flotation, while for difficult-to-beneficiate mixed copper ores and difficult-to-beneficiate oxidized copper ores, hydrometallurgy or a combined method of flotation and hydrometallurgy is employed.

Imagine you have a big pile of rock. Only a tiny part of this rock is valuable copper. The rest is just common stone. If you try to extract copper directly from this rock, you will spend a lot of money. You will ship a lot of waste rock. You will use huge amounts of energy to process it. The cost would be too high. You would lose money instead of making it. This is why beneficiation is so important. It is the first step that turns a low-value rock into a high-value product. It is like an “alchemist’s stone.”

Beneficiation means taking the raw copper ore and separating the valuable copper minerals from the unwanted waste rock. This process happens before smelting. Smelting is melting the copper minerals to get pure metal. After beneficiation, the copper content in the material is much higher. We call this high-copper material “copper concentrate.” This concentrate is easier to transport. It is also much cheaper to smelt.

For example, if your raw copper ore has only 0.5% copper, a beneficiation plant can turn it into a concentrate with 25-30% copper. This concentrate is 50 to 60 times richer than the original ore. This means you only need to transport and smelt 1/50th or 1/60th of the original rock volume to get the same amount of copper. This saves a lot of money on transport. It saves a lot of money on smelting. It also makes mining more profitable. So, beneficiation is a key step. It makes the whole copper production chain work. Without it, most copper mines would not be able to make money.

Most copper in the world comes from sulfide copper ores. These are minerals where copper is chemically bonded with sulfur, like chalcopyrite. To get copper from these ores, we use a process called flotation. Flotation is the most common method for sulfide copper ores. It is a very effective way to separate fine particles.

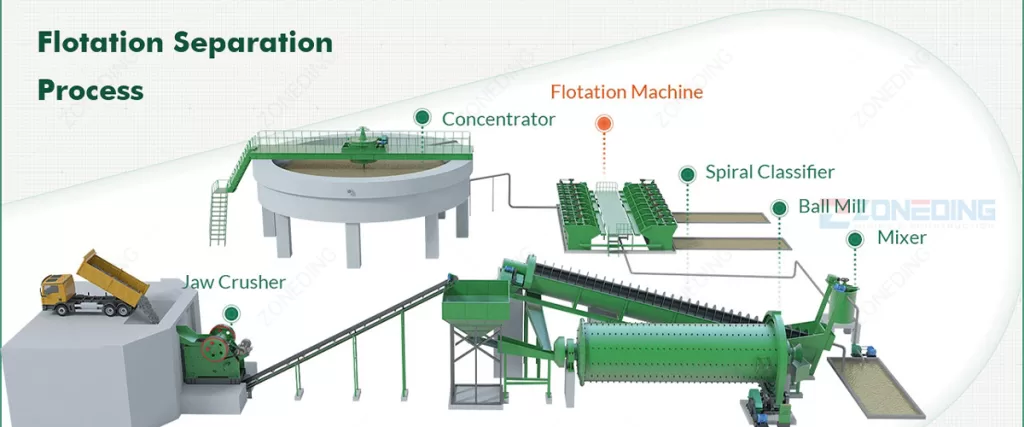

The flotation process starts by getting the ore ready. First, you need to crush the large pieces of ore. This breaks them down into smaller sizes. Then you need to grind these smaller pieces into a very fine powder. Grinding machines, like a Ball Mill or a Rod Mill, do this. Grinding is important. It frees the tiny copper mineral particles from the surrounding waste rock. Imagine the copper minerals as tiny jewels inside a big rock. You need to break the rock into pieces small enough to expose these jewels.

After grinding, you mix this fine ore powder with water. This forms a slurry. Then you add special chemicals to this slurry. These chemicals are called reagents. Some reagents make the copper mineral surfaces “water-repellent.” This means they do not like water. Other reagents create small air bubbles in the mixture. When you pump air into the mixture, these air bubbles attach to the water-repellent copper mineral particles. The particles then float to the surface, carried by the bubbles. The waste rock particles, which still like water, sink to the bottom.

The copper-rich foam that forms on the surface is skimmed off. This foam is the “copper concentrate.” The liquid and waste rock left behind is called “tailings.” The copper concentrate then goes through more steps. It might be ground again and floated a few more times. This removes more waste and increases the copper content further. This is called cleaning flotation. Finally, the copper concentrate is thickened to remove most of the water. Then it is filtered to make it even drier. The final product is a high-grade copper concentrate ready for smelting. Flotation makes it possible to get a lot of copper from low-grade sulfide ores.

Sulfide copper ores are very common. But you can also find copper in oxide ores. In oxide ores, copper is chemically bonded with oxygen, not sulfur. There are also “mixed ores” that contain both sulfide and oxide copper minerals. These ores need different ways to extract copper. Flotation alone might not work well for them.

For pure oxide copper ores, flotation is often not effective. This is because oxide copper minerals do not float well with the same reagents used for sulfides. They are generally more difficult to make water-repellent. For these ores, hydrometallurgy is a common choice. Hydrometallurgy involves using a liquid solution to dissolve the copper directly from the ore. This process is called leaching. Usually, you use an acid solution, like sulfuric acid. The acid dissolves the copper. The copper then goes into the liquid. After leaching, you collect the copper-rich liquid. Then you use methods like solvent extraction and electrowinning to get pure copper metal. This is a very clean way to get copper. It produces high-purity copper cathodes. It often avoids the need for smelting.

For mixed ores, it becomes more complex. You have both types of copper. You might use a combined approach. You could use flotation first to recover the sulfide copper minerals. Then, you might take the remaining ore (which is now richer in oxide copper) and leach it. This means you use two different methods to get the most copper out. Sometimes, you might even try to “sulfidize” the oxide minerals. This means you treat them with chemicals to make their surface behave more like a sulfide. Then you can try to float them. But this can be complicated and costly.

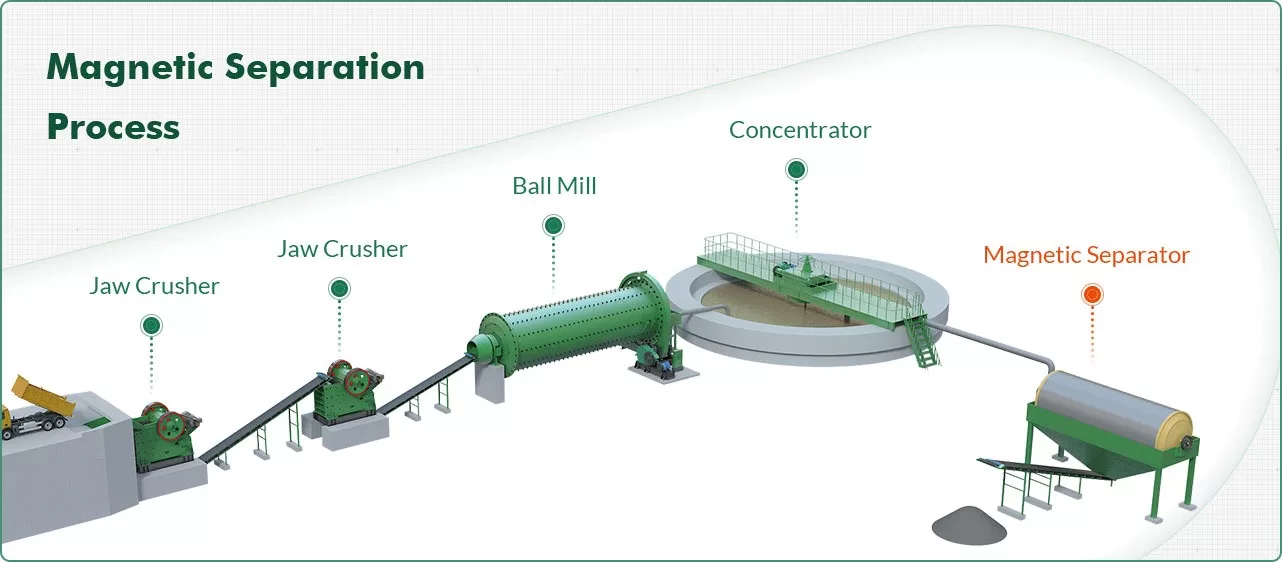

So, while leaching is a very strong option for oxide ores, it is not always the only option. The best way to process oxide or mixed copper ores is to do a professional beneficiation test. This test will tell you exactly what minerals are in your ore. It will show how they behave. Then, based on the test results, you can choose the best process flow. This might be flotation, leaching, a combination, or even other methods like gravity separation (Spiral Chute or Shaking Table) or magnetic separation (Magnetic Separator) for specific ore types. Each ore is unique. A custom solution is always best.

Crushing and grinding machines are essential for copper beneficiation. They break down the ore. This releases the valuable copper minerals. But these machines use a lot of power. They can easily account for 30% to 50% of the total energy cost in a copper plant. This is a huge expense. You want to make this step as energy-efficient as possible.

The key to cutting energy use is optimizing particle size control. You need to break the ore just enough. Do not break it more than needed. If you grind the ore too fine, it wastes energy. It also creates too many “fines” (very tiny particles). These fines can cause problems in later stages like flotation. They can make the concentrate difficult to filter. So, finding the optimal particle size is critical.

We use a multi-stage crushing approach. This means using several crushers in sequence. First, a Jaw Crusher takes the large rocks from the mine. It breaks them into smaller pieces. Then, a Cone Crusher or Impact Crusher breaks these pieces even smaller. Using multiple stages lets each crusher work at its most efficient size range. This saves energy compared to trying to do too much size reduction in one machine. After crushing, you use screens (Vibrating Screen) to separate the ore by size. Any pieces that are still too big go back to the crusher. This “closed circuit” system ensures you only grind what is necessary.

For grinding, a common approach is stage grinding. This means grinding the ore in steps. You might use a Rod Mill first for coarse grinding. Then a Ball Mill for finer grinding. This also helps save energy. Modern grinding mills also use energy-efficient motors and smart control systems. These systems adjust grinding settings automatically. They help maintain the correct particle size. This reduces power waste. By focusing on smart crushing and grinding, you can significantly cut down on your electricity bill. This makes your copper operation much more profitable.

A low copper recovery rate is a big problem. It means you are leaving valuable copper in the waste. You are losing money. Many factors can affect how much copper you get out. If your recovery rate is low, you need to check several things. It could be a broken link in your process chain.

One key area is flotation reagents. These are the chemicals you add to the slurry. They make the copper minerals float. If you use the wrong type, the wrong amount, or add them at the wrong time, your recovery will drop. Some reagents are collectors. They attach to copper minerals. Some are frothers. They make stable bubbles. Some are modifiers. They control how other minerals react. If these are not balanced, your copper might not float, or too much waste might float with it. Always ensure fresh, good quality reagents.

Water quality is another important factor. The water you use in flotation is not just a carrier. It can affect how the reagents work. If your process water has too many dissolved salts, or certain ions, it can interfere with flotation. For example, some ions can activate unwanted minerals. They make them float. Other ions can depress copper minerals. They stop them from floating. Using clean water or treating your process water can make a big difference. Sometimes, even the temperature of the water can affect recovery.

Finally, process parameters are critical. These are the settings of your machines and the conditions in the flotation cells (Flotation Machine). Things like:

Some copper ores are truly “stubborn.” They are low-grade, meaning very little copper. They are hard-to-process, perhaps because the copper minerals are very fine or mixed tightly with other minerals. They might also have many other minerals that you do not want. These are called “associated minerals.” They can be metals like iron or zinc, or gangue minerals like talc. These stubborn ores need special treatment.

The first step for stubborn ore is always detailed mineralogical analysis. You need to know exactly what minerals are in your ore. You need to know how big they are. You need to know how they are connected. This helps identify the challenge. Is the copper very fine? Are there too many impurities that float with copper? This information is like a map for your ore.

Based on this map, you might need a complex or combined beneficiation flow sheet. For example:

Copper ore beneficiation plants handle large amounts of material. They use chemicals and water. This means they produce waste: tailings (solid waste), wastewater (liquid waste), and sometimes exhaust gas (air waste). Governments around the world have very strict rules for environmental protection. You must meet these rules. Achieving “green and eco-friendly production” is not just good for the planet. It is required for your license to operate.

Tailings management is a major concern. Tailings are the finely ground waste rock left after beneficiation. They often contain residual chemicals and sometimes trace amounts of heavy metals. You cannot just dump them anywhere. Modern plants use tailings dams that are carefully designed and built to be stable and prevent leaks. They often use dry stacking methods. This means removing as much water as possible from the tailings. This creates a more stable pile. It also reduces the need for large, wet tailings ponds. The recovered water can be recycled. This saves fresh water.

Wastewater treatment is also very important. Water from the plant contains chemicals and fine particles. You cannot release it directly into rivers or groundwater. You need to treat it first. This involves processes like flocculation (making small particles clump together so they settle). It includes pH adjustment and heavy metal removal. The goal is to make the water clean enough for discharge or, even better, to recycle it back into the plant. Water recycling saves fresh water. It also reduces the volume of wastewater that needs treatment and discharge.

Exhaust gas control might be needed, especially if your ore contains sulfide minerals that produce sulfur dioxide during drying or calcining. You might use scrubbers or filters to clean the air. The goal is to minimize air pollution.

Overall, achieving green production involves several steps:

Building a copper ore beneficiation plant is a big investment. The cost can vary a lot. It depends on many things: the size of the plant, the complexity of your ore, the technology you choose, and local conditions. You need to plan carefully to control costs and choose the right machines.

The total cost includes:

The copper mining industry is always looking for new ways to improve. People are asking about “black technologies.” This means advanced, cutting-edge solutions. Smart control and automation are definitely major trends for the future of copper ore beneficiation. They are not magic, but they make things work better.

Traditional beneficiation plants rely on human operators. They watch meters and adjust valves. This can be prone to human error. It can be slow to react to changes in the ore. Modern plants use smart control systems. These systems use sensors. They collect data on everything: slurry density, pH, reagent flow, air flow, and more. Computers then analyze this data in real-time. They make automatic adjustments. This keeps the process running at its optimal point. For example, if the ore coming in changes (its grade, or mineralogy), the system can adjust reagent dosages automatically. This keeps the recovery rate high. It avoids wasting expensive chemicals.

Automation takes this a step further. It means machines do tasks without human involvement. This can include automatic sampling systems. These take samples of the ore and concentrate. They analyze them instantly. It can also include robotic systems for maintenance or material handling. Automation reduces the need for human operators in dangerous areas. It improves safety. It also makes the process more consistent.

Other advanced technologies include:

Q 1: Why is copper beneficiation necessary for low-grade ore?

A: Copper beneficiation is necessary because raw low-grade copper ore has very little copper. It is too expensive to transport and smelt it directly. Beneficiation increases the copper content, making later processing steps much more economical.

Q 2: What is the main method for processing sulfide copper ore?

A: The main method for processing sulfide copper ore is flotation. This process separates copper minerals from waste rock by making copper particles float to the surface using air bubbles and chemicals.

Q 3: Can I process oxide copper ore with flotation?

A: Flotation is generally less effective for oxide copper ores compared to sulfide ores. Hydrometallurgy (leaching) is often preferred for oxide ores, or a combination of methods for mixed ores.

Q 4: What is the biggest cost in copper beneficiation?

A:Energy consumption, especially from crushing and grinding, is often the biggest operating cost in copper beneficiation. Optimizing particle size control and using efficient machines can greatly reduce this cost.