全站搜索

Search the entire website

Search the entire website

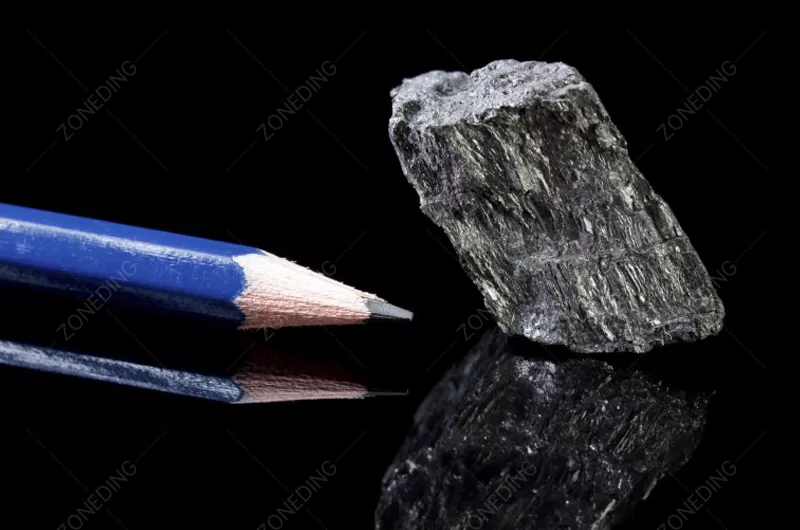

Graphite is one of the crystalline minerals of carbon element. It has excellent properties such as lubricity, chemical stability, high temperature resistance, electrical conductivity, special thermal conductivity, plasticity, and coatability. Its application fields are very wide.

Graphite, as a crystalline mineral of carbon, possesses excellent lubricity, chemical stability, high-temperature resistance, electrical conductivity, special thermal conductivity, plasticity, and coating properties, making its applications extremely wide-ranging.

Based on its crystal morphology, graphite ore is generally divided into two main categories:

Cryptocrystalline Graphite: Crystal diameters are less than 1 micron, and their crystal forms are difficult to distinguish under a microscope. Due to the greater difficulty in beneficiation, industrial applications typically require a higher raw ore grade, and it can usually be used directly after grinding. Its overall industrial performance is inferior to that of crystalline graphite.

Crystalline Graphite: Includes flake and lump graphite, with crystal diameters greater than 1 micron. The raw ore grade of this type of ore is usually low, requiring beneficiation and purification before it can be used in industrial production, but due to its excellent quality, its application range is extremely wide.

With the rapid development of the world industry, graphite materials and their composite materials, as emerging materials in the 21st century, have been regarded as one of the important industrial mineral raw materials at home and abroad.Graphite, with its unique and excellent properties—including outstanding lubricity, chemical stability, high-temperature resistance, good electrical conductivity, special thermal conductivity, and good plasticity and coating properties—has extremely broad application prospects in industrial and high-tech fields.

| Characteristic | Importance to You | Typical Use |

|---|---|---|

| Flake Size | Larger flakes mean higher market value and specific applications | Refractories, Lubricants, Battery Anodes |

| Fixed Carbon Content | Determines purity and suitability for high-tech uses | Batteries, Electrodes, Nuclear Reactors |

| Electrical Conductivity | Essential for battery and electrode applications | Batteries, Electrodes, Conductive Coatings |

| Heat Resistance | Allows use in high-temperature environments | Refractories, Foundries |

The beneficiation process of graphite ore aims to extract high-quality graphite from the raw ore and is adjusted according to the different forms of graphite crystals. This is a key step that transforms raw ore into a valuable industrial resource through a series of carefully controlled stages.

The main beneficiation process includes the following stages:

The graphite concentrate after flotation separation typically has a fixed carbon content of 90-97%. If higher purity graphite is required, further purification processes are needed, which include methods such as high-temperature treatment and thermal refining. It is worth noting that different types of graphite require different extraction processes.

Graphite ore often has a medium to soft hardness. Graphite flakes are naturally soft and break easily. This happens during crushing and grinding. Large flakes can break into small ones. This greatly lowers their market value. Large flakes are worth much more than small ones. Many plants grind too much to separate minerals. This wastes resources. It harms the value.

My experience says you need a “gentle philosophy” for grinding and flotation. This means multi-stage crushing. It means multi-stage grinding. It means stage grinding. It means stage flotation. In each step, you must “selectively break and separate.”

For crushing, you should use machines like a Jaw Crusher for primary breaking. Avoid impact crushers. They can damage the flake structure. For grinding, the main idea is “more crushing, less grinding.” Use a Rod Mill for rough grinding. It uses line contact for breaking. This causes less damage to flaky graphite. After this, you must have efficient screening equipment. Use a Vibrating Screen. It quickly removes large flakes. These flakes are already separated. This stops them from being over-ground in the next mill. This “letting go” strategy saves large flakes. It is very important for successful graphite processing.

Flotation is the core of graphite processing. But the real skill is in multi-stage flotation. This means roughing, cleaning, and scavenging. It also involves re-grinding and re-flotation of concentrates. Simple one-time flotation will not give high purity. It can also lose large flakes. Graphite floats naturally. We use chemicals like kerosene or diesel as collectors. Pine oil or alcohol works as a frother. You must control the pulp density. You must control the pH. You must control chemical amounts. You must control air flow. This stops unwanted minerals like pyrite and mica from floating. It also saves graphite. For low-grade ores, use “one roughing, multiple cleaning, multiple scavenging” steps. During cleaning, you can re-grind the concentrate. This separates any remaining impurities. Then you float again. This “re-grind and re-float” step is important. It raises the final concentrate to over 90% carbon. It can even reach over 99% for battery-grade graphite. But you must control grinding strength here too. This protects large flakes.

| Stage | Purpose | Impact on You |

|---|---|---|

| Roughing | Initial separation of most graphite | High recovery, lower purity |

| Cleaning | Repeated flotation for higher purity | Improves fixed carbon content, reduces impurities |

| Scavenging | Recovering graphite from tailings of roughing | Increases overall graphite recovery |

| Re-grinding | Further liberation of graphite from impurities | Essential for achieving very high purity |

Graphite ore rarely comes pure. It often has impurities like mica, sulfides (like pyrite), and other silicates (like quartz). These impurities must be removed. This ensures the final graphite concentrate meets purity standards. Different methods are used for different impurities.

Mica removal is important. Mica has a flaky shape, similar to graphite. This can make it float with graphite. To remove mica, you can use selective flotation. This requires specific chemicals. These chemicals make mica sink. They let graphite float. Also, careful control of grinding is key. It helps to separate mica from graphite without breaking graphite flakes. After flotation, you can use a Shaking Table. This can separate residual mica based on density differences.

Sulfide removal, especially pyrite, is critical. Pyrite contains sulfur. Sulfur is an undesirable element in many graphite applications. Pyrite also floats. You can remove pyrite through flotation. This uses different chemical conditions than graphite flotation. You can also use magnetic separation. Pyrite is often weakly magnetic. A Magnetic Separator can remove it. For higher efficiency, you can do this after roughing flotation. This removes most graphite. Then, the remaining material (middlings) goes through magnetic separation.

Silicate removal (like quartz) often happens through flotation or gravity separation. After grinding, fine quartz can float with graphite. To prevent this, you can use depressants in the flotation process. These chemicals stop quartz from floating. Gravity separation, like using a Spiral Classifier or Jigging Separator Machine, is effective for coarser silicates. It separates them based on density. By using a combination of these methods, you can precisely remove various impurities. This ensures a high-purity graphite concentrate.

To get “battery-grade” graphite with 99.99% fixed carbon, flotation is usually not enough. You need further purification. This involves advanced methods like acid leaching or chemical purification. These methods remove very fine or stubborn impurities. These impurities stay even after multiple flotation steps.

Acid leaching is the most common method for ultra-high purity. It uses strong acids to dissolve impurities. These impurities can be silicates, metals, or sulfates. Hydrofluoric acid (HF) is very effective. It removes silicon and aluminum. Hydrochloric acid (HCl) removes iron and calcium. Sulfuric acid (H2SO4) helps with some metal impurities. The choice of acid depends on the remaining impurities. The process involves mixing graphite with acid. Then heating it. Then washing it very well. This step is expensive. It also has environmental and safety risks. So, it should be done only when necessary.

Chemical purification can also involve high-temperature methods. For example, heating graphite to very high temperatures (over 2000°C) can vaporize impurities. This is called thermal purification. It creates very high-purity graphite. This method is even more costly than acid leaching. It uses a lot of energy.

Before using these advanced methods, make sure your flotation process is optimized. This is important. High-efficiency flotation can raise the carbon content to 90-97%. This reduces the burden on acid leaching. This saves costs. It also makes acid treatment more efficient. Remember, treating acid waste is also very important. You need proper systems for safe disposal or recycling.

| Method | Purpose | Considerations for You |

|---|---|---|

| Acid Leaching | Removes residual metal and silicate impurities | High cost, safety risks, environmental impact |

| Thermal Purification | Vaporizes impurities at high temperatures | Very high energy consumption, specialized equipment |

| Optimized Flotation | Pre-purification to reduce load on final steps | Reduces overall purification costs and complexity |

Building an efficient graphite beneficiation plant needs a complete set of reliable machines. These machines work together. They turn raw graphite ore into high-purity concentrate. Each piece of equipment plays a key role. It ensures smooth operation. It also ensures high product quality. It protects the valuable flakes.

For crushing, you will need a Jaw Crusher for primary breaking. This reduces large lumps. For grinding, a Rod Mill is often best. It helps avoid over-grinding of flakes. It protects their integrity. It is better than a Ball Mill for this. After grinding, you need screening to classify the graphite. A Vibrating Screen is common. For very fine particles or precise classification, a High-Frequency Screen works better.

For flotation, you need a Flotation Machine. You also need a Mixer for preparing the pulp. The flotation circuit should have multiple stages. For impurity removal, a Magnetic Separator is crucial for magnetic impurities. A Shaking Table or Spiral Classifier can handle specific gravity separation. Finally, for dewatering and drying, a High-Efficiency Concentrator thickens the slurry. Then a filter press removes more water. For final drying, a Drum Dryer is used. It is important to pick the right equipment for each step. This ensures an efficient and high-quality graphite production line. It also protects flake integrity.

Graphite beneficiation uses a lot of water. It also produces large amounts of tailings. These are the waste materials after graphite is removed. These are big environmental challenges. To build a truly green and sustainable graphite plant, you must focus on recycling. You must also turn waste into value. This is how you make an eco-friendly process.

Water resource management is very important. You should design a closed-loop water system. Water from thickeners and filter presses should be treated. Then it should be reused in the process. This greatly cuts down on fresh water use. It also minimizes wastewater discharge. Using a High-Efficiency Concentrator can help. It quickly separates solids. This allows more water to return for reuse. This approach lowers water bills. It reduces discharge fees. It ensures stable production.

Tailings treatment and utilization are also key. Tailings should not just be waste. They are a potential secondary resource. You can dewater tailings using filter presses. This creates a solid cake. This method reduces the land needed for tailings ponds. It lowers the risk of water pollution. You can also find ways to use these tailings. Some can be used as construction materials. They can be used for land reclamation. Or they can be backfilled into mines. Tailings might even contain valuable minerals. These include quartz or feldspar. They can be used as raw materials for ceramics or glass. Planning these solutions from the start is very important. It meets environmental rules. It also provides long-term cost savings. It makes your plant more sustainable and profitable.

Graphite ore often has a medium to soft hardness. Graphite flakes are naturally soft and break easily. This happens during crushing and grinding. Large flakes can break into small ones. This greatly lowers their market value. Large flakes are worth much more than small ones. Many plants grind too much to separate minerals. This wastes resources. It harms the value.

My experience says you need a “gentle philosophy” for grinding and flotation. This means multi-stage crushing. It means multi-stage grinding. It means stage grinding. It means stage flotation. In each step, you must “selectively break and separate.” For crushing, you should use machines like a Jaw Crusher for primary breaking. Avoid impact crushers. They can damage the flake structure. For grinding, the main idea is “more crushing, less grinding.” Use a Rod Mill for rough grinding. It uses line contact for breaking. This causes less damage to flaky graphite. After this, you must have efficient screening equipment. Use a Vibrating Screen. It quickly removes large flakes. These flakes are already separated. This stops them from being over-ground in the next mill. This “letting go” strategy saves large flakes. It is very important for successful graphite beneficiation.

Flotation is the core of graphite processing. But the real skill is in multi-stage flotation. This means roughing, cleaning, and scavenging. It also involves re-grinding and re-flotation of concentrates. Simple one-time flotation will not give high purity. It can also lose large flakes. Graphite floats naturally. We use chemicals like kerosene or diesel as collectors. Pine oil or alcohol works as a frother. You must control the pulp density. You must control the pH. You must control chemical amounts. You must control air flow. This stops unwanted minerals like pyrite and mica from floating. It also saves graphite. For low-grade ores, use “one roughing, multiple cleaning, multiple scavenging” steps. During cleaning, you can re-grind the concentrate. This separates any remaining impurities. Then you float again. This “re-grind and re-float” step is important. It raises the final concentrate to over 90% carbon. It can even reach over 99% for battery-grade graphite. But you must control grinding strength here too. This protects large flakes.

| Stage | Purpose | Impact on You |

|---|---|---|

| Roughing | Initial separation of most graphite | High recovery, lower purity |

| Cleaning | Repeated flotation for higher purity | Improves fixed carbon content, reduces impurities |

| Scavenging | Recovering graphite from tailings of roughing | Increases overall graphite recovery |

| Re-grinding | Further liberation of graphite from impurities | Essential for achieving very high purity |

You now know that graphite beneficiation is complex. It needs careful planning. It needs tailored solutions for each ore type. So, choosing the right supplier is very important. You need a partner who truly understands your specific graphite ore. They must offer full-process solutions. This partnership is vital for your project’s success.

Here is what to look for when choosing a professional supplier:

Q 1: Why is flake integrity important in graphite beneficiation?

A: Flake integrity is crucial because larger graphite flakes command higher market prices. Damaging them during processing lowers the overall value of your product.

Q 2: What is the main method for separating graphite from impurities?

A: Flotation is the primary method for separating graphite. Graphite naturally floats, and specific chemicals enhance this separation from other minerals.

Q 3: Can I achieve battery-grade graphite with just flotation?

A: No, typically flotation alone cannot achieve battery-grade graphite purity. Further purification steps like acid leaching or thermal treatment are usually required.

Q 4: Why should I use a rod mill instead of a ball mill for grinding graphite?

A: A Rod Mill grinds graphite more gently. It helps maintain the flake integrity. This is unlike a Ball Mill, which can break the flakes into smaller, less valuable pieces.

Q 5: How can I reduce environmental impact in a graphite plant?

A: You can reduce environmental impact by implementing a closed-loop water recycling system. You should also focus on efficient tailings dewatering and finding ways to utilize tailings as a resource.