全站搜索

Search the entire website

Search the entire website

A successful kaolin plant design is a value creation strategy. It starts by defining your target market—be it fillers, ceramics, or high-end coatings—and then engineering a specific kaolin processing technology to achieve the required quality specifications.

This is the first and most important question. Your answer will determine every subsequent design decision. Each end market has a completely different set of non-negotiable quality requirements.

Your target market dictates your process design. Paper coating grade kaolin requires ultra-fine particles and the highest possible whiteness. Ceramic grade kaolin prioritizes chemical purity and controlled particle size. Filler grade kaolin is the least demanding.

You must design your plant backwards from your customer’s specification sheet.

Your plant is a factory for producing specific physical and chemical properties.

This is the highest value market. The kaolin is used as a pigment to make paper glossy and opaque. This requires:

In ceramics, kaolin provides the white-firing body for porcelain and sanitaryware. The key requirements are:

Kaolin is used as a functional filler in products like rubber, plastics, and adhesives to add bulk and improve properties.

| Target Market | Primary Requirement | Implied Plant Design |

|---|---|---|

| Paper & Coatings | Whiteness & Fineness | Wet Process, Purification, Ultra-fine Grinding |

| Ceramics | Chemical Purity | Purification (Magnetic), Controlled Grinding |

| Fillers | Cost-Effectiveness | Dry Process, Standard Grinding |

This is the fundamental design choice that will define your plant’s capability, cost, and complexity. It’s a strategic decision between producing a lower-value product with lower investment, or a high-value product with a higher investment.

The dry process is a simpler, lower-cost option for producing filler-grade kaolin. The wet process is a more complex, higher-investment route that is essential for producing high-purity, high-whiteness kaolin for paper and coatings.

You cannot make a premium product with a basic process.

The choice between dry and wet processing is a commitment to a specific market segment.

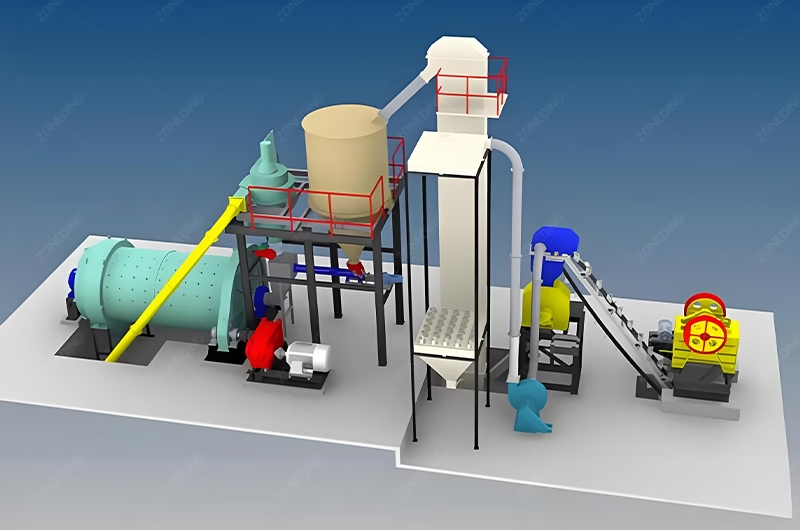

In the dry process, raw kaolin is crushed, dried in a rotary dryer, ground in a mill (like a Raymond mill), and then classified by air to separate the fine product. The process is straightforward, has lower capital and operating costs, and uses no water. However, it is very difficult to remove impurities like iron and titanium oxides. Therefore, the final product’s whiteness is limited by the quality of the raw material. This design is perfect for the filler market.

The wet process is the only way to achieve the highest levels of quality. Raw kaolin is mixed with water and a dispersing agent to form a slurry. This slurry then undergoes a series of purification steps that are impossible in a dry system. This includes screening, magnetic separation to remove iron, and sometimes chemical bleaching. The purified slurry is then ground to ultra-fine sizes in a media mill. Finally, the water is removed using filter presses and a spray dryer. The result is a product with exceptional whiteness and fineness, but the plant is much more complex and expensive to build and operate.

| Feature | Dry Process | Wet Process |

|---|---|---|

| Capital Cost | Lower | Higher |

| Operating Cost | Lower | Higher (water, chemicals, dewatering) |

| Product Quality | Lower (limited by raw material) | Highest (impurities are removed) |

| Key Advantage | Cost-Effective | Maximum Value Creation |

| Typical Market | Fillers, Low-grade ceramics | Paper, Coatings, High-grade ceramics |

The grinding mill is the central piece of equipment in your plant. However, in kaolin processing, its job is not to crush, but to gently separate the clay’s microscopic platelets. The wrong choice of mill can destroy the very properties that make kaolin valuable.

The ideal mill depends on the process. For dry grinding, a Raymond mill is a good choice for gentle grinding. For kaolin wet grinding, a media mill (ball mill) using ceramic media is essential for ultra-fine grinding without contamination.

I advise clients to think of this as “delamination,” not grinding. We want to peel the layers apart, not shatter them.

The choice of mill must align with your process (wet or dry) and quality goals.

This is a workhorse for dry process kaolin plants. Its rolling and plowing action is gentler than high-impact mills, which helps preserve the platelet structure of the kaolin. It is an air-swept mill, meaning it integrates well with a high-efficiency air classifier, which is critical for controlling the fineness of the final product in a dry circuit.

A standard VRM must be used with caution for kaolin. The high-compression grinding action can be too aggressive and may break the delicate platelets, reducing the product’s performance as a coating pigment. However, they can be considered for specific applications where particle shape is less critical.

In wet processing, a ceramic ball mill or a stirred media mill is the undisputed champion. These mills are filled with small, hard ceramic beads. As the kaolin slurry passes through, the intense shearing action created by the moving beads effectively delaminates the kaolin stacks into individual platelets. Critically, using ceramic lining and ceramic media prevents iron contamination, which is essential for maintaining high whiteness.

| Mill Type | Best Process | Grinding Action | Key Benefit |

|---|---|---|---|

| Raymond Mill | Dry | Attrition / Shearing | Preserves platelet shape in dry grinding |

| Vertical Roller Mill | Dry (with caution) | Compression / Shearing | High capacity, but risk of particle damage |

| Ball / Media Mill | Wet | Attrition / Shearing | Ultra-fine delamination with no contamination |

Simple grinding only gets you so far. To create a truly premium kaolin product, your plant design must include value-adding steps like purification and calcination. These processes transform good kaolin into great kaolin.

A world-class design incorporates kaolin purification using high-gradient magnetic separators to remove staining impurities. For the highest value, a calcined kaolin production line using a rotary kiln creates a product with superior brightness and opacity.

These are not just extra steps; they are strategic investments that can increase your product’s selling price by several times.

Adding these modules to your plant design is how you move into the high-margin segment of the market.

The primary enemy of whiteness is iron oxide (rust) and titanium oxide impurities in the raw clay. The most effective way to remove them is in a wet process. The kaolin slurry is passed through a High-Gradient Magnetic Separator. This machine uses powerful electromagnets to capture the weakly magnetic iron and titanium particles, physically removing them from the product. This single step can dramatically increase the ISO brightness of the final product.

Calcination is a thermal process where purified kaolin is heated in a rotary kiln to temperatures between 600°C and 1000°C. This process does two things:

| Process | Goal | Key Equipment | Result |

|---|---|---|---|

| Purification | Remove staining minerals | High-Gradient Magnetic Separator | Increased Whiteness |

| Calcination | Create a new crystal structure | Rotary Kiln | Superior Whiteness, Opacity, and Performance |

A kaolin plant is an intricate system. Focusing only on the main processing units while neglecting the supporting subsystems is a recipe for operational failure.

A complete turnkey solution must integrate all critical subsystems: slurry preparation (blunging), dewatering (filter presses), drying (spray dryers for wet process), and specialized material handling and packaging systems designed for fine powders.

I have seen plants with a fantastic mill that are constantly shut down because their dewatering system can’t keep up. The entire system must be balanced.

Every part of the process must be engineered to work in harmony.

For customers in the paper and coatings industry, the average particle size is not enough. They need to know the exact particle size distribution (PSD). Your plant must be designed to control this with precision.

PSD is controlled by the classification system. In a dry process, a high-efficiency air classifier is used. In a wet process, a series of hydrocyclones or a centrifugal classifier separates the slurry into different size fractions, allowing for the creation of tailored products.

Controlling the PSD is how you create products with specific performance characteristics, such as high gloss or good barrier properties.

Classification is the brain of the operation.

In a dry grinding circuit, the air classifier is the key. By adjusting the rotor speed and airflow, you can change the “cut point” – the size at which particles are either accepted as product or rejected back to the mill. A high-quality classifier can produce a very sharp cut, resulting in a product with a narrow and consistent PSD.

Wet processing offers even more precise control. A series of hydrocyclones can be used to split the kaolin slurry into coarse and fine streams. For the most demanding applications, a centrifugal classifier can be used. This allows a producer to create multiple products with different PSDs from a single feed stream, targeting different high-value applications.

Your choice of plant design is the single biggest factor that will determine your project’s financial outcome. It dictates your initial investment, your operating costs, and the price your product can command in the market.

A simple dry process plant represents a lower initial investment but limits you to the competitive, low-margin filler market. A complex wet process plant with purification and calcination requires a much higher investment but allows you to produce high-value products with strong competitive advantages.

The right design is the one that aligns with your business strategy and market opportunity.

This is a classic business decision presented through an engineering lens.

This model focuses on minimizing production costs to compete on price in the filler market. The initial investment estimation is lower. The key to success here is operational efficiency and scale. Your plant must be designed to be a reliable, low-cost producer. Your competitiveness comes from your low price point.

This model focuses on creating a superior product that can be sold at a premium price. The project feasibility depends on achieving specific quality targets for brightness, fineness, and purity. The initial investment is substantial, but the potential profit margins are much higher. Your competitiveness comes from your product’s unique performance characteristics, which commodity producers cannot match. The ROI analysis often shows a very attractive return, despite the higher upfront cost.

Designing a kaolin plant is a journey in value creation. The process begins with a strategic choice about your target market and product value. This decision then guides every technical choice, from the core process—wet or dry—to the selection of grinding, purification, and calcination technologies. A well-engineered plant is not just a collection of machines; it is a finely tuned system designed to transform a raw mineral into a high-performance product, securing your competitive advantage in the market.