全站搜索

Search the entire website

Search the entire website

A successful limestone grinding plant design transforms raw quarried limestone into fine powder with precise particle size distribution, tailored for applications like construction (cement, asphalt), agriculture (soil amendment), industrial fillers, and Flue Gas Desulfurization (FGD).

This is the foundational question for the entire design process. The intended end-use of the calcium carbonate powder dictates all subsequent engineering and equipment selection decisions.

The target market determines the necessary product fineness (mesh size), as well as requirements for purity, whiteness, and particle shape. This data forms the basis of the process flow and directs the selection of the core grinding technology.

The plant is not just producing powder; it is manufacturing a specific raw material for industrial applications.

After defining the product specifications, the next step is to select the central component of the plant: the grinding mill. These three technologies have distinct operating principles and are suited for different applications and scales.

The choice of mill is based on the required production capacity, final product fineness, and energy efficiency targets. For most modern, large-scale limestone projects, the vertical roller mill offers the highest energy efficiency. Raymond mills are suitable for smaller capacities, while ball mills are often used for ultra-fine grinding applications.

An analysis of each limestone grinding mill technology is necessary to make an informed decision.

| Mill Type | Optimal Application | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Raymond Mill | Small to medium capacity (1-20 TPH), producing powder from 80-400 mesh. | Lower initial investment cost, mechanically simple and reliable technology. | Higher energy consumption per ton produced, limited in achieving very fine products. |

| Vertical Roller Mill (VRM) | Medium to large capacity (10-100+ TPH), producing powder from 200-1250 mesh. | High energy efficiency (30-50% less than ball mills), integrates drying, grinding, and classifying functions in one unit, has a small footprint. | Higher initial investment cost, more complex machinery requiring specialized maintenance. |

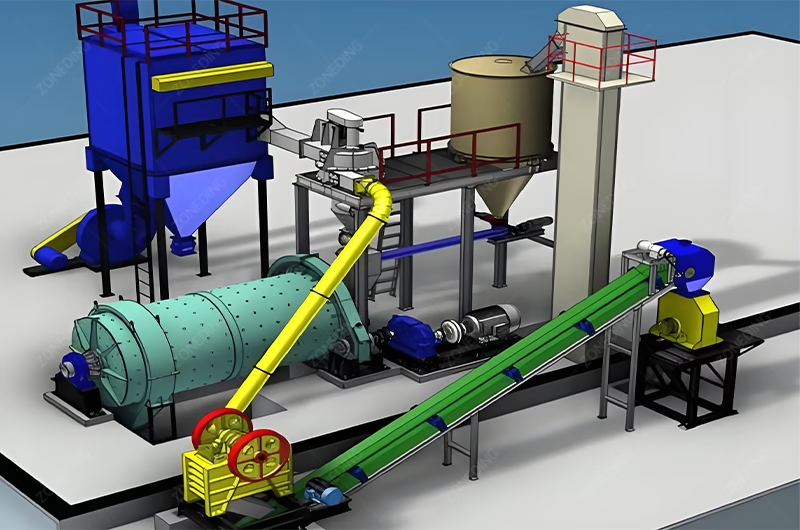

| Ball Mill | All capacity ranges, especially for ultra-fine (<10 microns) and high-whiteness applications. | Can produce a superior, more rounded particle shape, mechanically robust. | Very high energy consumption, requires a large footprint, needs separate classifier and often a pre-dryer. |

Budgeting for a limestone powder production line must account for the entire system, not just the main grinding mill. A complete plant is an integrated circuit of various machines.

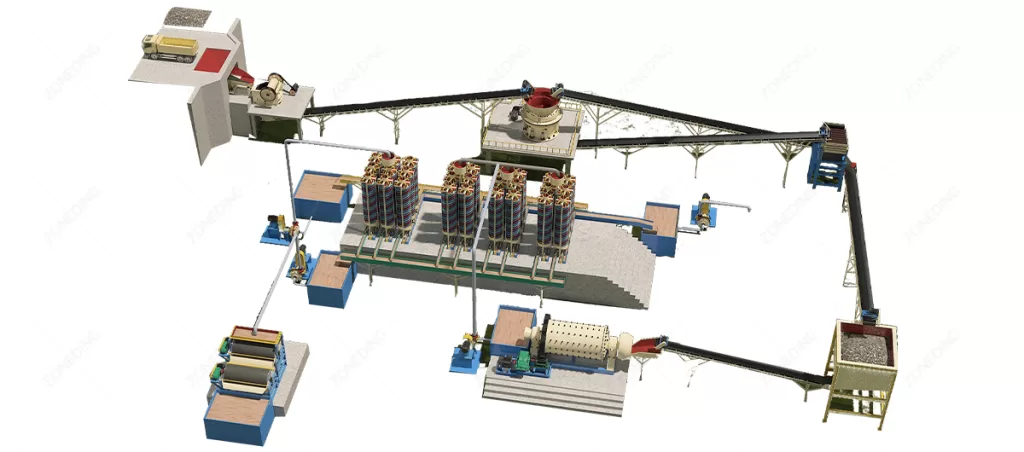

A complete grinding plant includes systems for primary crushing, material feeding, grinding, classification, dust collection, and product storage. Every component must be correctly sized and balanced with the others to ensure stable and efficient plant operation.

The following components are essential for a functional production line.

The two largest recurring operating costs in a grinding plant are electricity and the replacement of wear parts. The most significant operational risk is shutdown due to environmental non-compliance. A proper design must address these factors from the start.

Energy efficiency and environmental control are fundamental design criteria for a profitable plant. A modern design incorporates an energy-efficient mill, such as a VRM, and a fully integrated dust collection system, which serves as both an environmental control device and a product recovery unit.

The design objective should be the lowest total cost per ton, which includes both capital and operational expenditures.

The physical layout of the plant significantly impacts both the initial construction cost and long-term operational efficiency.

An optimized layout minimizes the plant’s overall footprint, reduces the required length of material transport systems like conveyors, and incorporates plans for future expansion. A compact, vertical layout, which is often achievable with a vertical roller mill, can lead to considerable savings in land use, concrete, and structural steel.

Efficient spatial planning is a key component of cost control.

Limestone properties vary significantly by source. The plant’s design must be tailored to the specific characteristics of the raw material feed.

The hardness (measured by the Bond Work Index) and the moisture content of the limestone are critical design parameters. Hardness dictates the necessary motor power and influences the wear rate of grinding components. Moisture content determines if integrated drying capability is required.

It is essential to test the raw material before finalizing the equipment selection and design.

To receive an accurate and comparable technical proposal from an equipment supplier, a detailed list of project requirements must be provided.

An effective request for quotation (RFQ) includes specific data on the raw material, detailed product specifications, site conditions, and the desired level of automation. This enables the supplier to perform proper engineering and provide a tailored solution.

Providing the following information will result in a more precise and relevant proposal.

The design of a limestone grinding plant is a complex engineering task. By beginning with a clear definition of the final product and methodically addressing these key design questions, project developers can ensure a more informed and strategic approach. This structured process is the most effective way to develop an efficient, profitable, and sustainable operation.