全站搜索

Search the entire website

Search the entire website

Lithium, often dubbed “white petroleum,” is undeniably a cornerstone of the modern technological landscape. Its unparalleled electrochemical properties make it the material of choice for the anodes of high-energy-density batteries, powering everything from smartphones and laptops to the rapidly expanding fleet of electric vehicles (EVs). As global efforts to decarbonize intensify, the demand for lithium is set to skyrocket, making efficient and sustainable lithium ore concentration techniques more critical than ever.

This comprehensive guide delves into the essential processes, techniques, and crucial considerations involved in optimizing lithium ore concentration, paving the way for maximized extraction and responsible production.

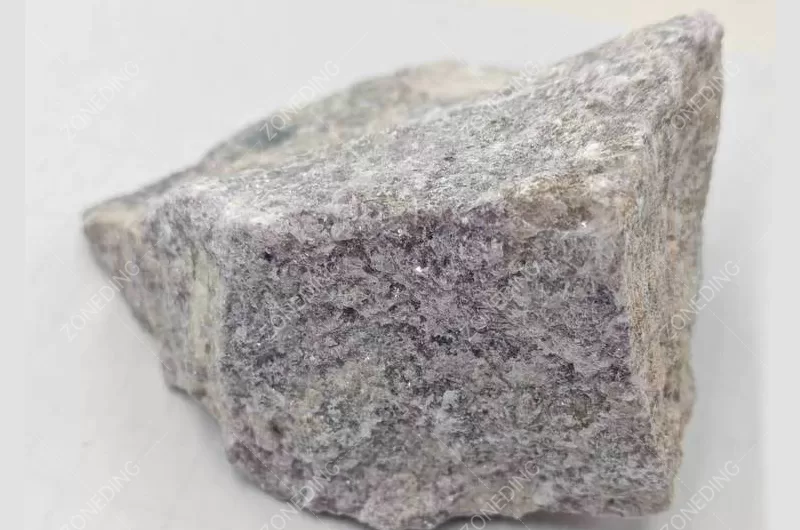

Lithium ore primarily consists of minerals such as spodumene, lepidolite, and petalite, with spodumene often being the primary focus due to its high lithium content. While many customers primarily focus on the Li₂O content and categorize their ore simply by primary mineral type like spodumene or lepidolite, the true “secret” to optimizing lithium extraction lies in a deeper, microstructural analysis of the ore. This includes meticulously examining embedment size and liberation characteristics, as well as identifying the types, amounts, and states of associated gangue minerals such as quartz, feldspar, mica, and various clay minerals.

| Characteristic | Why It Matters for You | Impact on Your Plant Operation |

|---|---|---|

| Microstructure | Determines how minerals break and separate | Guides crushing and grinding equipment choice |

| Embedment Size | Dictates the necessary grinding fineness | Affects energy consumption and potential for over-grinding |

| Gangue Minerals | Influences reagent selection and separation difficulty | Determines complexity of flotation circuit |

| Accurate analysis of your ore’s “genetic map” is essential for designing an efficient and cost-effective lithium beneficiation plant. |

Lithium ore beneficiation is a step-by-step journey. It takes raw ore to high-grade lithium concentrate. Each step is important. It adds value to the material. I believe a successful process balances efficiency, cost, and product quality.

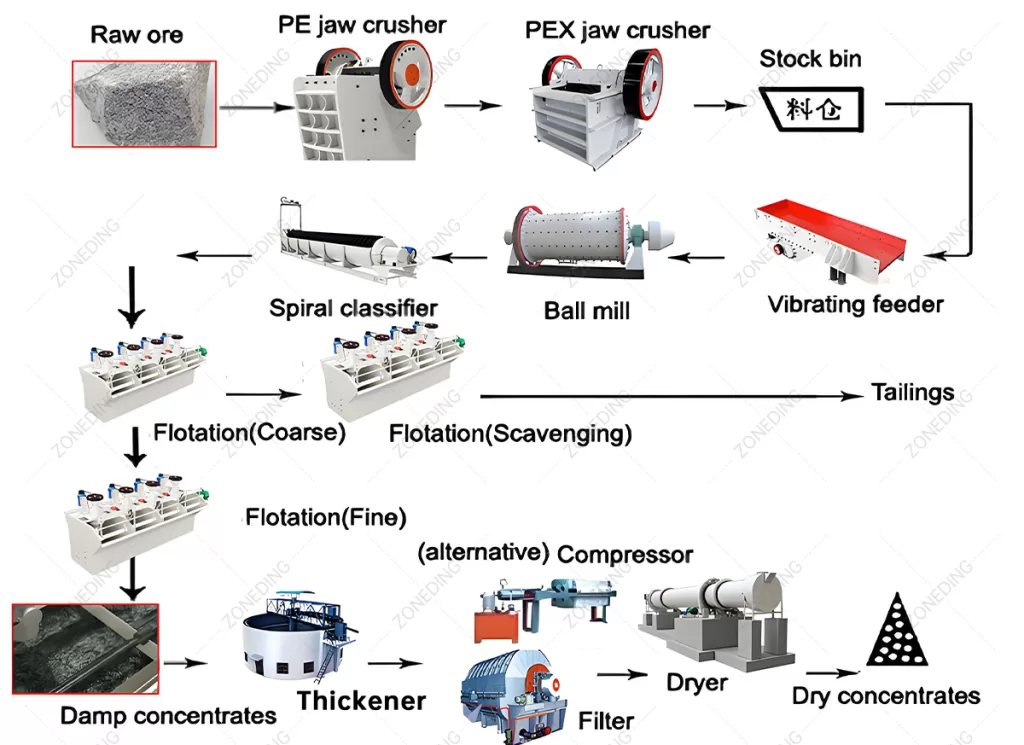

The journey usually begins with crushing. Big rocks become smaller pieces. Then, grinding reduces the particles even more. This liberates the valuable lithium minerals. After that, separation methods isolate the lithium. These often include flotation, but can also use gravity or magnetic methods. Finally, dewatering and drying remove water. This prepares the concentrate for sale or further processing. Each stage needs careful design. It needs the right equipment. This makes sure your plant runs smoothly. It also helps it produce a high-quality product.

Flotation is the most important process in lithium ore beneficiation. It is also the most common. It makes high-grade lithium concentrates from complex ores. This process works on mineral surface properties. Different minerals react differently to water and chemicals.

In flotation, specific chemicals called reagents are added to the ore pulp. These reagents make lithium mineral particles attractive to air bubbles. The bubbles attach to the lithium. They lift it to the surface. It forms a foam layer. The waste minerals stay in the water. They do not float. The foam is collected. It is then processed further. This is how lithium is separated. The biggest challenge is making sure only lithium floats. You must stop other minerals from floating. This needs careful control of reagents. It also needs precise control of the pulp’s chemistry.

| Aspect | Importance for Your Plant | Benefit |

|---|---|---|

| Selectivity | Separates valuable lithium from complex gangue minerals | High purity concentrate |

| Recovery Rate | Maximizes the amount of lithium extracted | Increased overall yield and profitability |

| Adaptability | Can be tailored for various lithium mineral types | Flexible for different ore characteristics |

Complex lithium ores like lepidolite and petalite pose unique challenges. They can be very hard to process. Their structure and fine intergrowths make separation difficult. To achieve high recovery for these “hard-to-process” lithium minerals, you need a sophisticated approach. This often involves multi-stage grinding, careful flotation, and pre-desliming.

My experience shows that a multi-stage grinding strategy is vital. This means grinding the ore in several steps. You do not grind it all at once. This avoids over-grinding. It ensures better liberation. For example, rough grinding can use autogenous mills. Then, fine grinding can use Ball Mills or Rod Mills. After each grinding stage, classify the material. Use a Spiral Classifier or hydrocyclone. This removes already liberated particles.

Pre-desliming is another key step. It removes fine clay minerals and slimes before flotation. These slimes can consume large amounts of reagents. They also hurt flotation efficiency. They can coat mineral surfaces. This makes them harder to float. By removing slimes first, you improve flotation conditions. This lowers reagent costs. It also boosts recovery. Then, a multi-stage flotation circuit is used. This includes roughing, cleaning, and scavenging. It allows for precise separation of different lithium minerals from gangue. This comprehensive approach is essential for recovering complex lithium minerals efficiently.

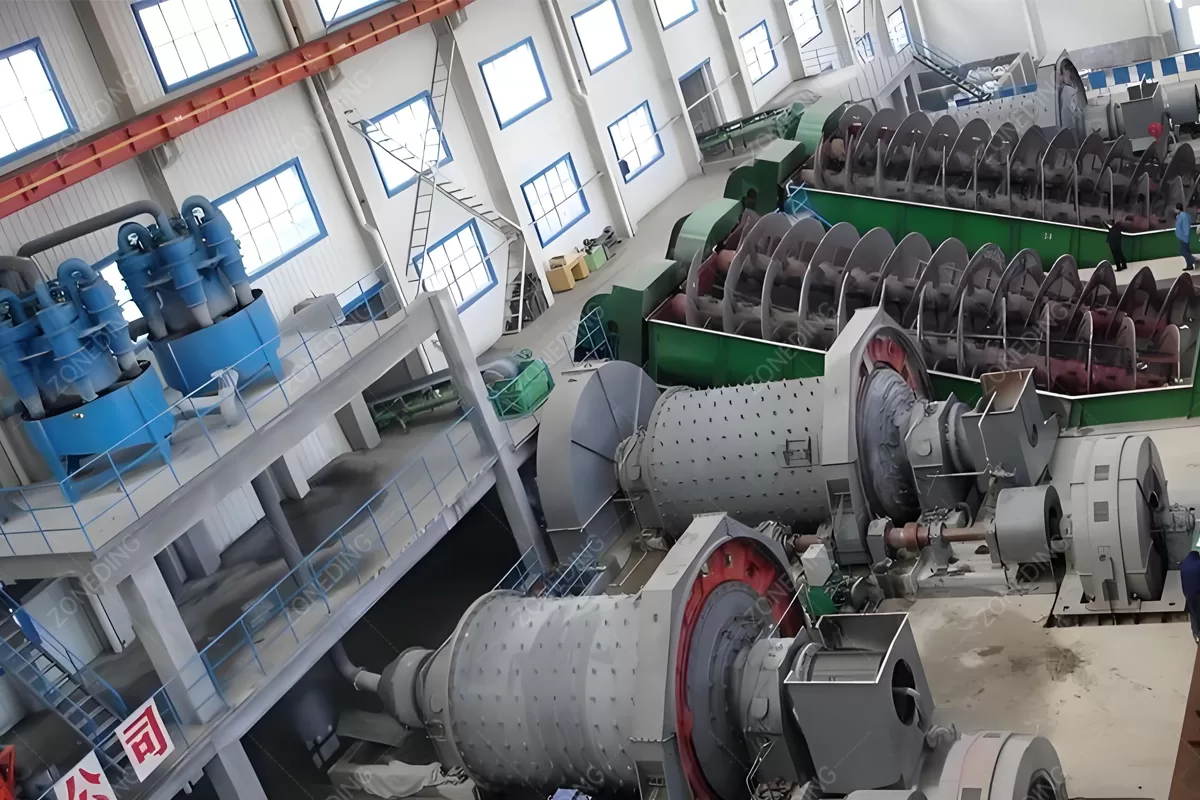

A modern lithium beneficiation plant needs a complete set of robust equipment. These machines work together to create a full-process, high-efficiency production line. Each piece of equipment plays a specific role. It ensures the smooth flow of material and optimal mineral recovery.

This is the primary stage. Raw ore, typically large, needs to be made smaller. This prepares it for grinding or separation. Lithium ore is brittle. So, we use multi-stage crushing. We combine this with efficient screening. This controls particle size. Our goal is “more crushing, less grinding.” This saves energy and improves efficiency. For primary crushing, a Jaw Crusher works well. For secondary crushing, a Cone Crusher or Impact Crusher is good. Efficient Vibrating Screens classify material.

After crushing, the ore needs more grinding. Grinding equipment, like a Ball Mill or Rod Mill, makes it finer. This frees the lithium from gangue minerals. Choosing the right fineness is vital. If too coarse, separation suffers. If too fine, too many slimes form. This wastes energy. It also hurts recovery. Mineralogical studies help find the best size. This balances recovery and cost. For lithium, which can slime, staged grinding is common. Staged separation is also used. This recovers good particles early. A Spiral Classifier often works with a ball mill.

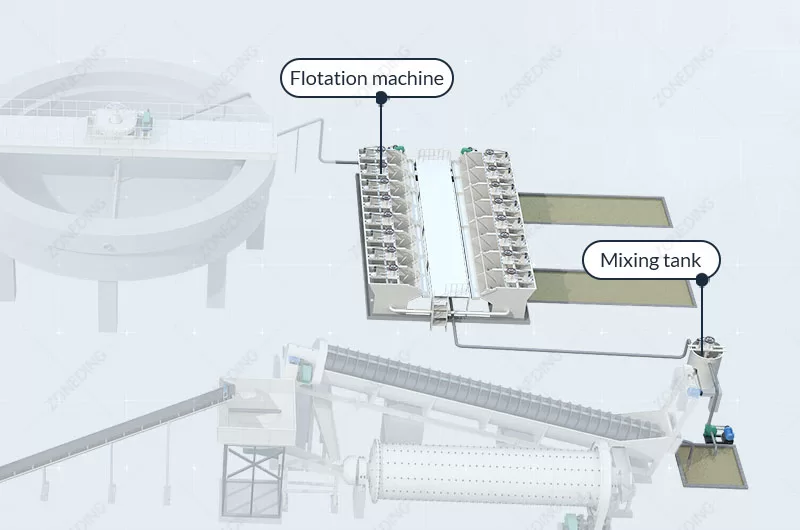

Flotation is the main technology for lithium beneficiation. It uses differences in mineral surface properties. Flotation reagents are added. Lithium particles attach to air bubbles. They float to the top. They form a foam product. Gangue minerals stay in the pulp. Reagent cost is a big operating cost. Optimizing reagents helps. Reducing reagent use lowers production costs. A Flotation Machine is central to this process. A Mixer prepares the pulp.

Flotation is dominant. But gravity separation and magnetic separation are also important. They help in specific situations. Gravity separation is good when density differences are large. It works for coarse particles. It is often a pre-concentration step. It removes low-grade gangue first. This reduces ore for flotation. It saves energy and reagent costs. Equipment includes Jigging Separator Machines, Shaking Tables, and Spiral Chutes.

Magnetic separation removes magnetic impurities. These include magnetite and hematite. It uses weak or strong Magnetic Separators. This depends on mineral magnetism. For ores with high magnetic minerals, magnetic separation improves concentrate grade. It boosts flotation results.

After separation, the concentrate is still wet. It needs dewatering. This involves thickening and filtration. A High-Efficiency Concentrator is used for thickening. It reduces water content significantly. Then, filter presses (like plate-and-frame filter presses) remove more water. For very low moisture requirements, especially for chemical-grade products, drying is needed. A Drum Dryer can reduce moisture to required levels. These steps are crucial for product quality. They also reduce transportation costs.

Flotation is the core of lithium concentrate production. But customers often face a problem. No single “magic reagent” or “universal process” works for all lithium ores. Different lithium minerals, like spodumene, lepidolite, and petalite, react differently to flotation reagents.

The real art of flotation is customized reagent systems. Also, you need precise water quality control. The choice and ratio of collectors, modifiers, and inhibitors must be highly customized. You must consider ore properties, pulp pH, water quality, and even pulp temperature. I saw a project where untreated hard water was used for flotation. This greatly increased reagent consumption. It led to very low recovery. By building a complete recycled water management system, flotation efficiency improved a lot. This system included water softening, pH adjustment, and removing specific ions. This means the water treatment system is as important as the Flotation Machine itself in a lithium plant.

| Factor | How It Impacts Your Plant | Action to Take |

|---|---|---|

| Ore Type | Different lithium minerals require specific reagents | Conduct detailed mineralogical analysis |

| Pulp pH | Controls mineral surface charge and reagent effectiveness | Install automated pH monitoring and adjustment |

| Water Quality | Hardness and impurities can interfere with reagent function | Implement a comprehensive water treatment system |

Lithium ore beneficiation creates large amounts of tailings and wastewater. This is especially true for flotation. These are big environmental issues. To build a “green revolution,” you must aim for “zero discharge.” You must also focus on resource utilization. This means turning waste into value.

1. Water Resource Management:

| Environmental Challenge | Solution for Your Plant | Long-Term Benefits |

|---|---|---|

| Water Consumption | Implement closed-loop water recycling | Reduced operational costs, minimized water discharge |

| Tailings Volume | Adopt dry stacking and potential re-utilization | Smaller environmental footprint, new revenue streams |

| Energy Use | Optimize processes for energy efficiency (e.g. grinding) | Lower carbon footprint, reduced operational costs |

The mining industry is moving towards smart operations. Lithium ore beneficiation plants can greatly benefit from automation and smart upgrades. These advancements lead to more stable production. They boost efficiency. They also reduce human errors. This makes your plant “smarter” and more efficient.

1. Real-time Monitoring and Data Analysis:

| Benefit | How It Is Achieved | Impact on Production |

|---|---|---|

| Stable Efficiency | Real-time data, AI-powered adjustments | Consistent product quality, reduced variability |

| Higher Production | Optimized processes, reduced downtime | Increased throughput, maximized output |

| Cost Savings | Optimized resource use, predictive maintenance | Lower energy, reagent, and repair costs |

Investing in a lithium ore beneficiation plant is a big step. It needs careful economic assessment. You also need strong risk control. This ensures your project is profitable. It needs careful planning from the start.

First, perform a detailed feasibility study. This includes market analysis. It looks at lithium demand and prices. It also assesses your ore reserves and quality. It estimates capital costs. These include equipment, construction, and infrastructure. It also forecasts operating costs. These include energy, reagents, labor, and maintenance.

Second, conduct a thorough risk assessment. Identify all potential risks. These include market price fluctuations. They also include technical challenges in processing your specific ore. Environmental regulations can change. Supply chain disruptions can happen. Labor availability is a factor. Develop mitigation strategies for each risk. For instance, diversify your off-take agreements. Also, use proven technologies. Ensure your process design is flexible. This helps handle variations in ore quality.

Third, build a robust financial model. This predicts cash flows. It calculates key financial metrics. These metrics include Net Present Value (NPV) and Internal Rate of Return (IRR). It also includes payback period. Stress-test your model. Change key assumptions. See how they affect profitability. This helps you understand the project’s resilience. It ensures “profitability” is not just a hope, but a solid plan.

You now understand that lithium ore beneficiation is complex. It needs tailored solutions for each ore type. So, choosing the right supplier is very important. You need a partner who truly understands your specific lithium ore. They must offer full-process solutions. This partnership is vital for your project’s success.

Here is what to look for when choosing a professional supplier:

Q 1: What is the main difference between spodumene and lepidolite processing?

A: Spodumene is brittle and needs careful grinding to avoid over-sliming. Lepidolite has a layered structure. It often creates more fine slimes, needing different reagent systems and desliming.

Q 2: Why is multi-stage grinding important for lithium ore?

A:Multi-stage grinding prevents over-grinding. It improves mineral liberation. This leads to higher recovery rates and lower energy consumption.

Q 3: How does water quality affect lithium flotation?

A: Water quality, especially hardness, can greatly impact reagent effectiveness. It can increase consumption. Proper water treatment and recycling are vital for efficient flotation.

Q 4: Can magnetic separation improve lithium concentrate grade?

A: Yes, magnetic separation can remove magnetic impurities like biotite and magnetite. This improves the purity of your lithium concentrate. It also helps subsequent flotation.

Q 5: What are the benefits of automation in a lithium plant?

A: Automation reduces human error. It increases production efficiency. It improves concentrate grade stability. It also lowers labor costs and prolongs equipment life.