全站搜索

Search the entire website

Search the entire website

Cocopeat (coconut coir) is the powdery substance between coconut husk fibers. After drying by Coco Peat Rotary Dryer, the coconut peat can be used in the field of plant cultivation or making into coconut bricks, which has high economic benefits.

A coconut coir dryer is industrial equipment specifically designed to gently remove the very high water content from coconut fiber and pith (coir/peat) using thermal energy, while minimizing damage to its physical structure and controlling dust.

Think of it as a system engineered for a light, fibrous material with extremely high initial moisture, often after a washing process.

A coconut coir dryer uses controlled heat and airflow, typically in a customized rotary drum system, to reduce high moisture content while preserving the coir’s structure, transforming it into a stable, lightweight, and valuable growing medium or other product.

Drying extremely wet coir drastically reduces transport costs, stabilizes the material for storage and sale, and enables its use as premium horticultural growing media (substrates, seedling mixes), its highest value application.

Drying transforms coir from a heavy, wet byproduct into a sought-after commodity.

ZONEDING helps you design a drying process that meets the specific quality requirements (moisture content, structure preservation) for your target market, especially high-value horticulture.

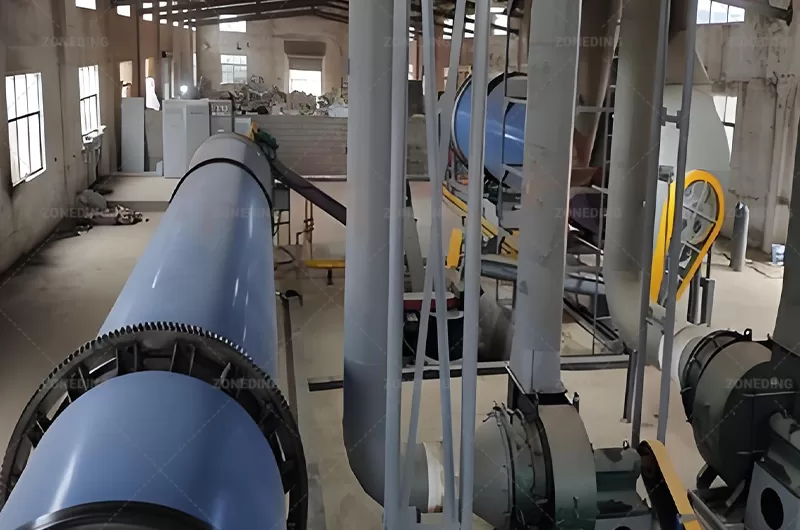

Modified rotary drum dryers are generally the most suitable and common technology for high-moisture coir. Airflow (flash) dryers often struggle with the initial wetness and can easily carry away too much light material.

Coir’s unique combination of properties dictates the best technology choice.

| Dryer Type | Handling High Initial Moisture | Handling Lightweight/Dusty Material | Preserving Structure | Common Use for Coir |

|---|---|---|---|---|

| Rotary Dryer | Good (with pre-dewatering) | Fair to Good (needs specific design) | Good (with controlled temp/time) | Most Common |

| Airflow Dryer | Poor (struggles with >60-65% moisture) | Poor (high material loss risk) | Fair | Rare / Specialized |

ZONEDING specializes in designing these customized rotary dryers, ensuring they effectively dry coir while minimizing material loss and preserving its valuable properties.

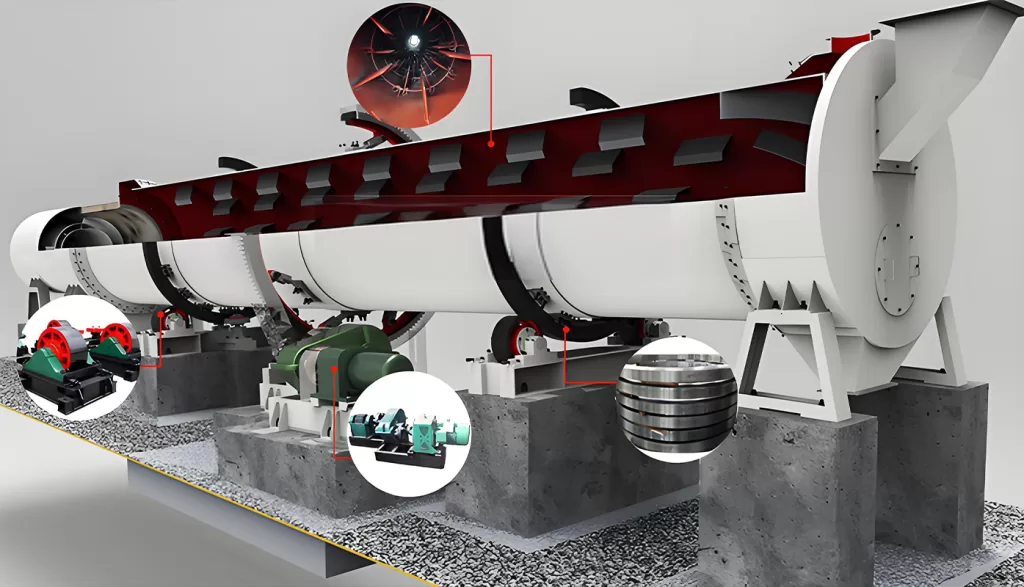

A Cocopeat Dryer, typically a customized rotary drum, works by gently tumbling the wet coir through a rotating cylinder. Controlled hot air flows through the drum, transferring heat to evaporate water, while specially designed internals minimize material loss and structural damage.

The process is carefully managed to suit coir’s delicate nature.

ZONEDING designs these systems ensuring the mechanics, thermodynamics, and airflow are optimized for gentle yet efficient coir drying.

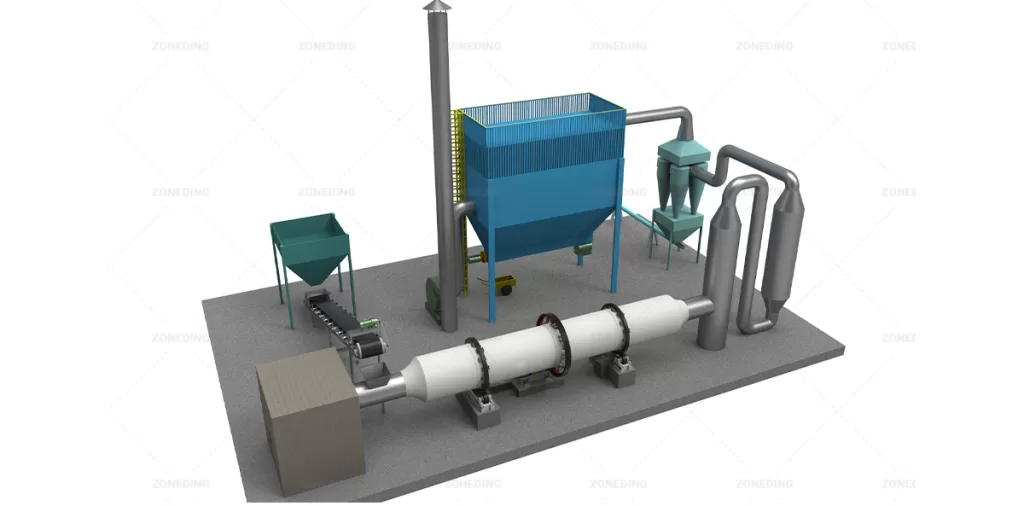

A complete coir processing line often includes raw material preparation (crushing/screening), potentially washing and dewatering, the dryer itself, a cooling system, fine screening/grading, dust collection, and finally packaging (compressing/baling/bagging).

Here’s a typical sequence of equipment:

ZONEDING can design and supply key components like the dryer, heat source, and associated handling, or work with partners to deliver fully integrated coir processing lines tailored to your specific product requirements.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

A coco peat dryer removes excess moisture from coco peat, a coconut husk byproduct used in horticulture. Drying ensures optimal quality for use as a soil amendment or growing medium. Reduces moisture content.

Drying coco peat reduces storage volume, prevents mold growth, improves handling, and enhances its water retention and aeration properties for plant growth. Improves product quality.

Common coco peat dryer technologies include rotary drum dryers, fluid bed dryers, and belt conveyors, selected based on processing capacity and desired dryness. Provides efficient drying.

Coco peat dryers use a controlled flow of heated air to evaporate moisture from the coco peat as it moves through the system, achieving the desired dryness level. Enables consistent results.