全站搜索

Search the entire website

Search the entire website

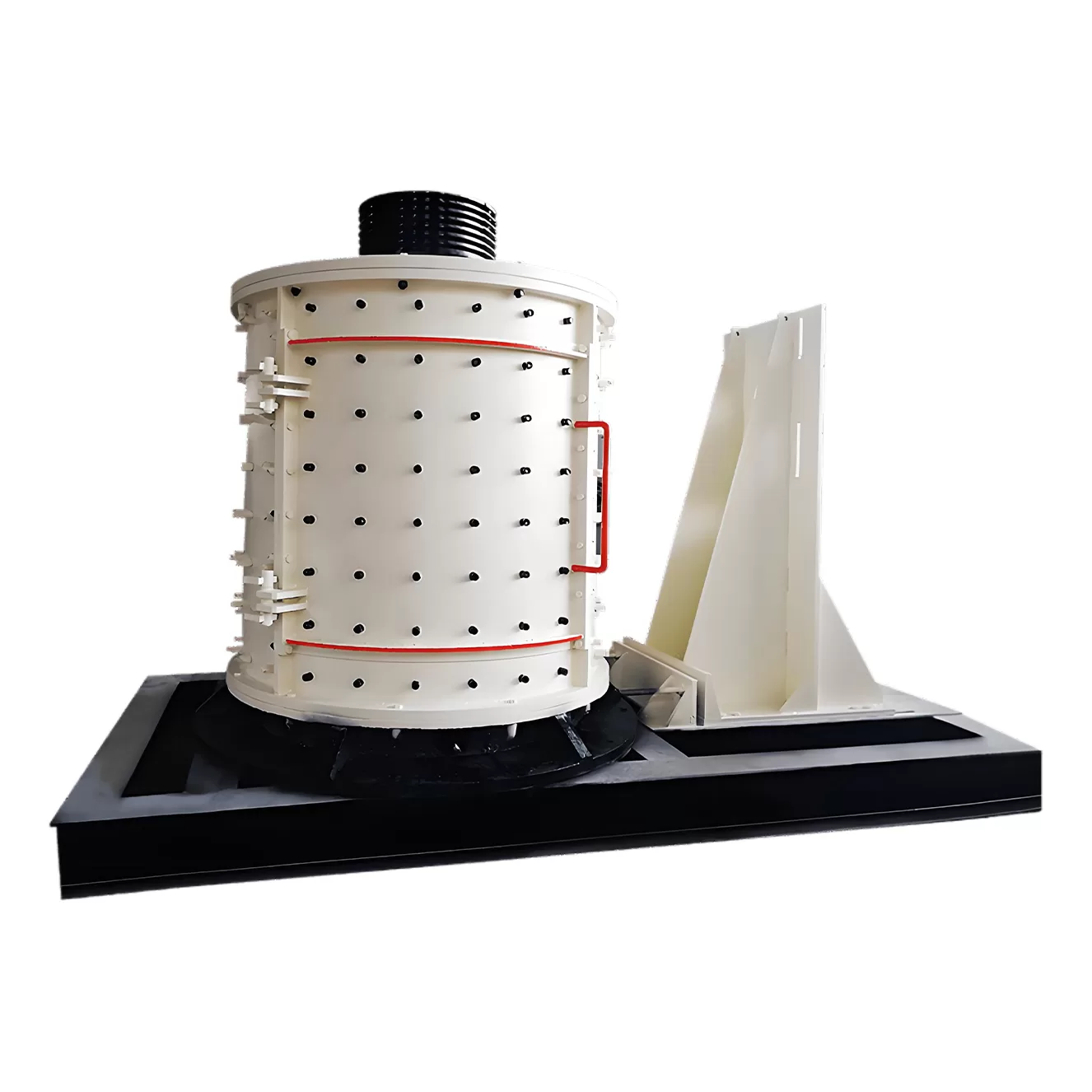

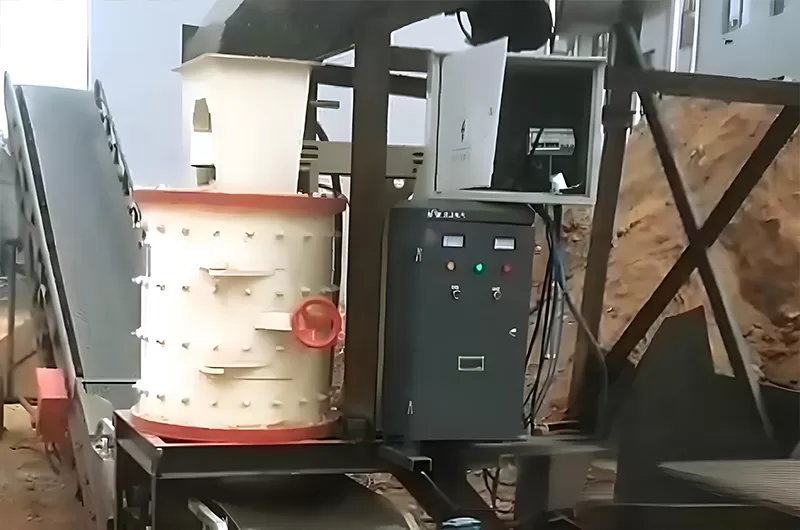

Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher.

A compound crusher, also called vertical compound sand maker, is a double-rotor primary impact crusher. The compound crusher is an ideal machine for crushing high-moisture and viscous materials, commonly used in small-scale crushing and sand production lines.

A Compound Crusher is a vertical shaft fine crushing machine that combines impact and grinding forces to reduce medium-hard materials without using a discharge screen.

It looks like a tall cylinder. Inside, a vertical rotor spins at high speed. It is effectively a hybrid between a hammer crusher and an impact crusher, but stood on its end.

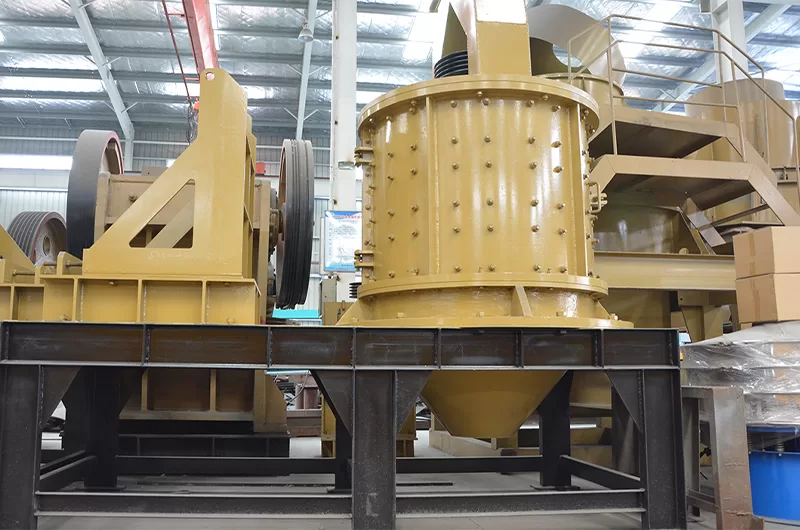

We design the compound crusher specifically for the secondary or tertiary crushing stage. It takes 100mm stones and reduces them to 0-5mm sand or powder. Because gravity assists the flow vertically from top to bottom, the material throughput is exceptionally high compared to horizontal machines.

Why choose this over a standard horizontal impactor? The answer lies in the conditions of your site.

Compound Crusher is used in mining, metallurgy, construction, and coal industries, especially for the production of clinker and aggregates in small and medium-sized cement plants.

This compound cone crusher has both primary and secondary crushing functions. With large crushing ratio, compound stone crusher can refine the material of 100-240mm to small particles below 3-5mm . The gap between hammer head and impact plate can be flexibly adjusted.

Designed with gridless structure, it is not easy to be clogged when dealing with materials containing a lot of slurry. Long bearing life and horizontal arrangement enables it to handle high temperature materials such as cement clinker. Low noise level of 75 decibels (dB) during operation and effective control of dust pollution. The wearing parts are made of special alloy material, which combines high hardness and toughness and multi-element alloy wear resistance, extending the service life to 2-3 times. The rear chamber is equipped with a screw or hydraulic pressure opener, which greatly facilitates the replacement of wearing parts.

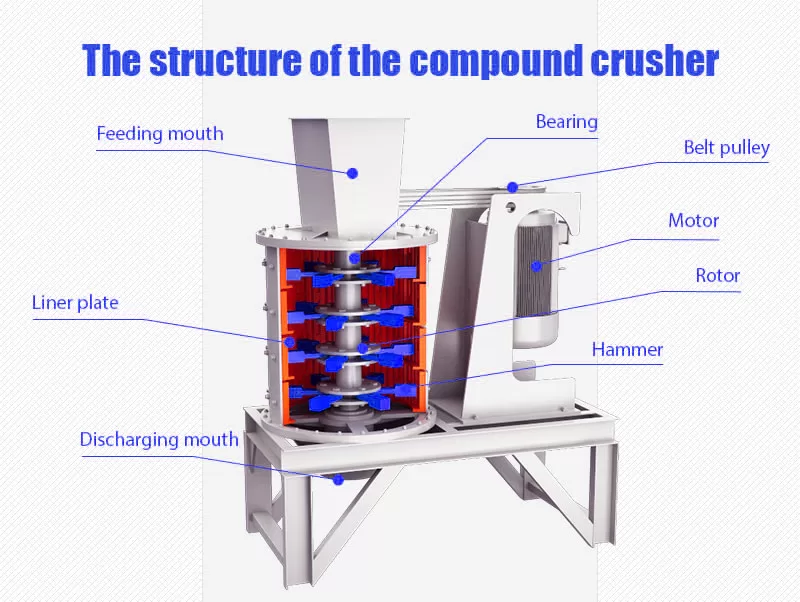

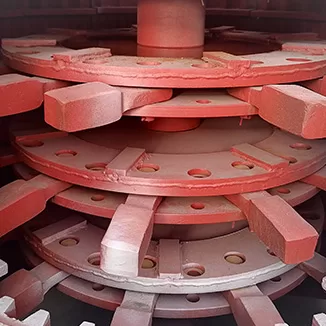

The vertical compound crusher machine is mainly composed of the crushing system (rotor, bearing, liner, hammer), transmission system (motor, pulley), in-and-out mouths, and other parts. Among them, the crushing system is the easy-wearing component, which is mainly introduced for you.

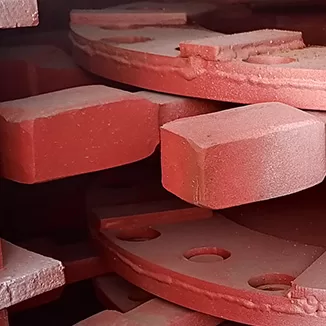

The flat hammer is a vulnerable part of the crusher, installed on the rotor. They break the material by striking it repeatedly.

The hammer head is made of wear-resistant alloy steel or bimetal thermal compound material and the weight is generally between 9-36 kg.

The rotor is a key part installed vertically in the crusher and is made of solid cast steel. Its circumference is equipped with hammers with adjustable clearance, responsible for high-speed rotation.

It has a special structure that won’t be worn once crushed. The speed and rotation direction of the rotor affect the crushing efficiency.

The liner plate refers to the wear-resistant plate inside the crushing chamber, which plays the role of grinding materials and protecting the cylinder from wear.

The special casting and heat treatment process makes the liner have good impact resistance.

The bearing assembly supports the rotation of the rotor and is critical to the smooth operation of the crusher.

Generally, double-row radial spherical roller bearings are selected, which have strong bearing capacity and good self-aligning performance.

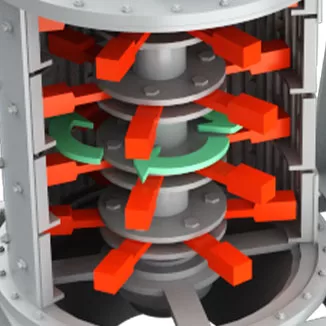

The material in the upper part of the machine perpendicular drops into the high speed rotating impeller,and under the high speed centrifugal force, it produces high speed impact and comminution with the other part of the material which distributes in the shape of umbrella around the impeller vertical composite crusher. The impeller and the housing will be crushed by swirl impact and friction between the impeller and the housing for many times, which will be discharged directly from the bottom, forming a closed circuit multiple cycles, and controlled by the screening equipment to achieve the required product size.

| Specification | Processing Capacity(t/h) | Motor Power(kw) |

| 800 | 5-15 | 4p 30kw |

| 1000 | 10-30 | 4p 55kw |

| 1250 | 20-60 | 6p 90kw |

| 1500 | 30-80 | 8p 110kw |

| 1750 | 40-100 | 8p 160kw |

A compound crusher is a crushing machine designed for secondary crushing of medium-hard materials. It efficiently reduces material size in a single stage. Achieve effective material crushing.

Compound crushers are suitable for materials like limestone, coal, shale, gypsum, and various ores. Ideal for achieving medium-fine sized particles in one step. Versatile crushing solutions.

Compound crushers offer high crushing ratio, simple structure, easy maintenance, and low operating costs. Save time and resources with single-stage crushing. Efficient crushing technology.

Material enters the crushing chamber and is impacted by high-speed hammers, then further crushed against breaker plates. Achieve consistent material breakdown and desired output.

Regularly inspect hammers, liners, and bearings for wear and tear. Lubricate moving parts and ensure proper discharge clearance for optimal crusher maintenance and lifespan.