全站搜索

Search the entire website

Search the entire website

A successful gypsum grinding plant design is a complete, integrated system. It is engineered based on a deep understanding of your specific raw material and your final product’s requirements. It balances capital investment with long-term operational efficiency.

This is the most critical question, and you must answer it before any other decisions are made. The end-use of your powder fundamentally changes the entire design philosophy and process flow.

Your end market dictates the core process. Building gypsum (stucco) requires a chemical process called calcination to remove water. Gypsum for cement is a simple physical grinding process for size reduction. These are two completely different plant designs.

Choosing the wrong path here is the most expensive mistake you can make. The equipment, energy requirements, and control systems are fundamentally different for each application.

The design of your entire factory hinges on this choice. One path involves a chemical transformation, while the other is purely mechanical.

The goal here is to produce beta hemihydrate gypsum (CaSO₄·½H₂O), the main ingredient in plaster and wallboard. This involves heating the raw gypsum dihydrate (CaSO₄·2H₂O) to drive off about 75% of its water. This gypsum calcination process is the heart of the plant. Your design must integrate a heat source and a reactor (like a rotary kiln or a grinding mill that calcines simultaneously) to achieve this precise chemical change. The control of temperature and residence time is critical to producing a quality product with the correct setting time.

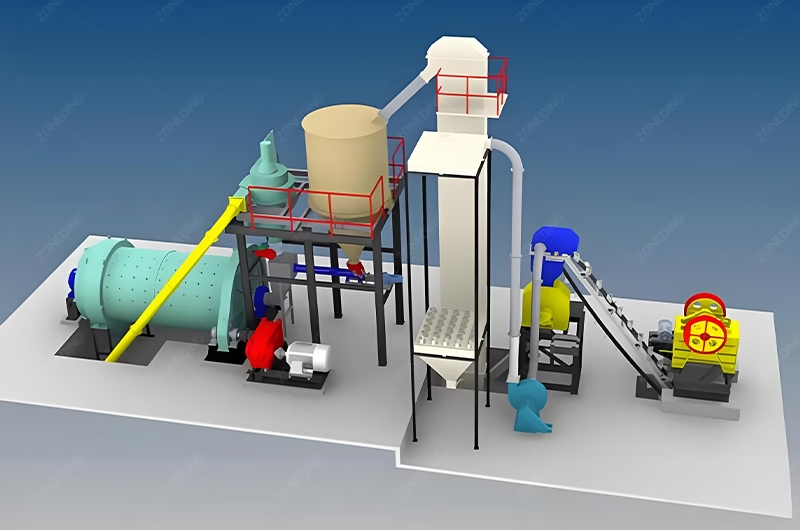

Here, the gypsum powder is used as a retarder to control the setting time of Portland cement. No chemical change is needed. The entire design focus is on efficient size reduction. The goal is to grind the raw gypsum dihydrate to a specific fineness (e.g., 90% passing 100 mesh) at the lowest possible cost per ton. The plant design is simpler, centered around crushing and grinding equipment like a ball mill, and does not require a large, complex heating and calcination system.

| Feature | Building Gypsum Plant | Cement Additive Plant |

|---|---|---|

| Core Process | Calcination (Chemical Reaction) | Grinding (Size Reduction) |

| Key Equipment | Calciner (Rotary Kiln), Grinding Mill | Jaw Crusher, Grinding Mill (Ball Mill) |

| Energy Needs | High (for heating) | Low to Moderate (for grinding) |

| Process Control | Complex (Temperature, Time) | Simple (Fineness) |

| Initial Investment | Higher | Lower |

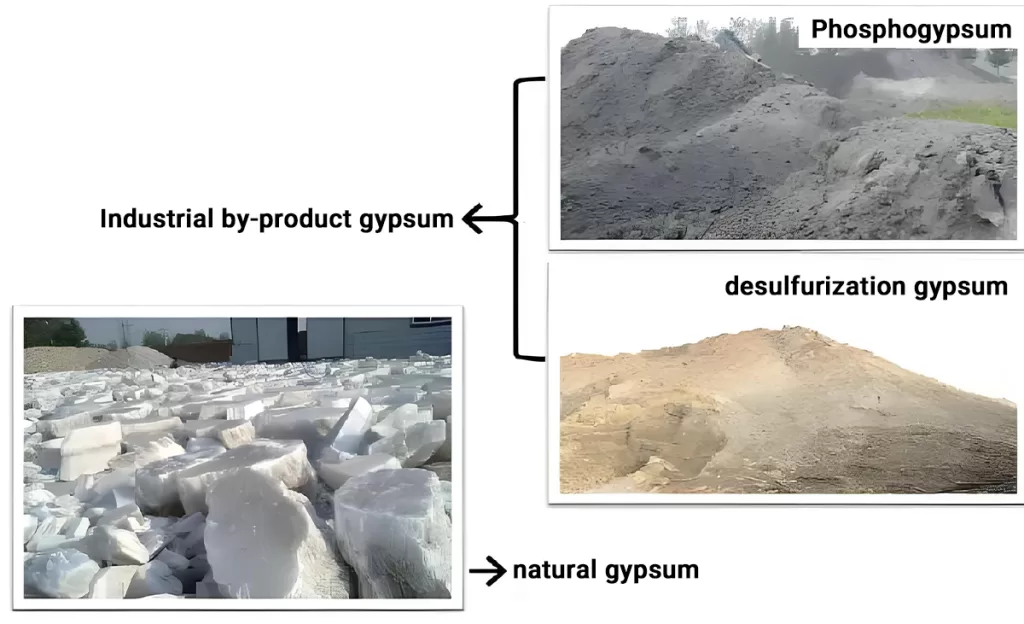

The physical and chemical properties of your raw material are the second most important factor in your plant design. A design optimized for clean, dry natural rock will fail completely if fed wet, sticky industrial by-product gypsum.

The design must be tailored to the raw material. Natural gypsum is easier to handle, while Flu-Gas Desulfurization (FGD) gypsum requires a more robust drying, feeding, and material handling system due to its high moisture and fine particle size.

I always advise my clients to design their plant for the worst-case scenario of their raw material, not the average or best-case.

Your raw material dictates the entire front-end of your plant. From the initial crusher to the feeding system, the design must prevent bottlenecks and ensure a consistent flow to the mill.

Natural gypsum rock is typically hard and has low surface moisture. The process begins with primary crushing, often using a jaw crusher or impact crusher, to reduce large rocks to a manageable size for the mill. Handling is straightforward with standard belt conveyors and feeders. While some drying might be needed, the thermal load on the system is generally low, requiring a smaller heat source.

FGD gypsum processing system design is far more complex. This material comes from power plants as a fine, wet filter cake with moisture levels often exceeding 15%. It is sticky and prone to clogging hoppers and feeders. The design must incorporate a specialized gypsum dryer or a grinding mill that can handle very high moisture loads. This means a much larger hot gas generator is needed. The material handling system must use steep-angled bins, anti-stick liners, and often specialized feeders to prevent flow problems. The entire system must be designed to evaporate huge amounts of water efficiently.

| Parameter | Natural Gypsum | FGD Gypsum |

|---|---|---|

| Moisture Content | Low (< 5%) | High (10-20%+) |

| Particle Size | Large Rocks | Fine Powder / Cake |

| Handling | Easy | Difficult (Sticky, Clogs) |

| Drying System | Small / Optional | Large / Essential |

| Feeding System | Standard | Specialized (Anti-clogging) |

The grinding mill is the heart of your plant. Choosing the correct type of mill is critical for achieving your production goals, controlling product quality, and managing operational costs.

The best mill depends on your capacity, raw material, and process. A vertical roller mill is ideal for large-scale, integrated grinding and drying of wet materials like FGD gypsum. A Raymond mill is a versatile choice for small to medium capacity. A ball mill is best for very fine grinding.

Each mill technology has its strengths, and the right design matches the technology to the specific needs of the project.

The selection of the grinding mill is a technical decision with major financial consequences on both your initial investment and long-term energy bills.

This is the modern solution for high-capacity plants, especially those using FGD gypsum. A VRM is a highly efficient machine that combines crushing, grinding, drying, and classifying into a single unit. Hot gas is ducted directly into the mill, drying the material as it is being ground. This makes it exceptionally good at handling high-moisture feeds. It offers low energy consumption and a compact footprint, but it has a higher initial investment cost compared to other options.

The Raymond mill is a proven, reliable workhorse for small to medium-scale gypsum powder production. It is an air-swept vertical roller mill that grinds and classifies material in one operation. It is less expensive than a large VRM and is very effective for natural gypsum. It can be integrated with a hot gas source to provide some drying capacity, making it a flexible option for many applications.

A ball mill is a robust and simple grinding machine used for producing very fine powders. In the gypsum industry, it is typically used in two scenarios: for grinding raw gypsum for cement plants, or as a finishing mill after a separate calcination process. It is not efficient at drying, so it is best suited for dry materials or as part of a multi-stage process.

| Mill Type | Best Application | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Vertical Roller Mill | High capacity; Wet materials (FGD) | High efficiency, low energy, combines drying | High initial cost |

| Raymond Mill | Medium capacity; Natural gypsum | Versatile, reliable, lower initial cost | Less efficient with very wet feed |

| Ball Mill | Fine grinding; Dry materials | Simple, robust, produces very fine product | High energy consumption, no drying capacity |

A successful factory is much more than a grinding mill. It is a complete system where every component is correctly sized and integrated to work together seamlessly. Overlooking these subsystems is a common design failure.

A complete gypsum powder line process flow must include robust subsystems for material feeding, heat generation (if calcining), dust control, product cooling, and finished product storage and handling. Each must be designed as part of the whole.

I have seen many projects fail because of an undersized dust collector or an inefficient cooling system. These are not afterthoughts; they are critical to performance.

A truly successful design treats the plant as a single, integrated organism.

At the core of a calcining plant is a system I call the “Golden Triangle”: the Mill, the Hot Gas Generator (HGG), and the Product Collector (Baghouse). These three must be designed as a single unit. The HGG provides the heat, the mill provides the grinding and residence time, and the baghouse acts as a separator. They are in a constant feedback loop. In addition, I always insist on a fourth critical component: a product cooler. After calcination, the hot stucco powder must be cooled quickly to stop the chemical reaction and prevent it from over-cooking into useless anhydrite. A simple water-jacketed screw conveyor can save an entire silo of product.

| Subsystem | Function | Design Consideration |

|---|---|---|

| Feeding System | Provides consistent material flow to the mill | Must be designed to handle the specific material (anti-clog for FGD) |

| Heat Generator (HGG) | Provides hot gas for drying and calcination | Must be sized for the maximum moisture load |

| Dust Collector | Captures finished product and controls emissions | Must handle the total gas volume (air + steam) |

| Product Cooler | Stops the calcination reaction; stabilizes product | Essential for quality control in building gypsum plants |

| Automation | Controls the entire process for stability | Ensures consistent quality and efficient operation |

Your customers are buying a product with specific performance characteristics. Your plant’s design is what guarantees you can consistently meet those specifications.

Product quality is engineered into the plant. Fineness is controlled by the mill’s classifier, whiteness is protected by using indirect heat sources, and setting time is precisely managed by the temperature and duration of the gypsum calcination process.

Quality is not achieved by accident; it is the direct result of specific design choices you make at the beginning of the project.

Every design decision has a direct impact on the final product your customers will receive.

The particle size distribution of your powder is critical. In modern grinding systems like a VRM or Raymond mill, fineness is controlled by an integrated dynamic classifier. By adjusting the rotational speed of the classifier from the control room, you can precisely and instantly change the fineness of the finished product to meet different customer requirements without stopping the plant.

For applications like high-end plaster, whiteness is a key selling point. If you use a direct-fired HGG burning a dirty fuel like coal, the ash and combustion products can contaminate the gypsum and give it a gray tint. A superior design uses an indirect heat source or burns a clean fuel like natural gas to protect the product’s natural whiteness.

For building gypsum, setting time is the most critical quality parameter. This is controlled entirely by the calcination process. Your design must ensure that every particle of gypsum receives the correct amount of heat for the correct amount of time to achieve the perfect conversion to hemihydrate. An advanced system design with precise temperature control loops and stable feed rates is essential for producing a consistent product day after day.

| Quality Parameter | Controlled By | Key Design Element |

|---|---|---|

| Fineness | Particle Size | Mill’s internal classifier speed |

| Whiteness | Color / Purity | Type of fuel and heat source (indirect vs. direct) |

| Setting Time | Chemical Composition | Precise temperature and time control in the calciner |

A poor gypsum processing plant layout can create daily operational problems and turn simple maintenance tasks into major, expensive projects.

Common pitfalls include not leaving enough space for maintenance access, creating an inefficient material flow that requires excessive conveying equipment, and failing to plan for future expansion. A good layout uses gravity where possible and prioritizes accessibility.

The physical arrangement of your equipment is just as important as the equipment itself. A smart layout pays dividends for the entire life of the plant.

A good layout saves you money on capital costs and makes the plant safer and easier to operate.

The most efficient layout follows a logical, linear path from raw material to finished product. It minimizes the distance material has to travel and uses gravity to its advantage. For example, the raw material stockpile feeds down into the crushing and grinding section. The product is then conveyed up to the top of the silos, from where it can be loaded into trucks or bags via gravity. This reduces the need for long, high-maintenance belt conveyors and bucket elevators, saving both capital and operating costs.

I have seen plants where a simple task like changing the oil in a gearbox requires building a scaffold because of a poorly placed pipe. This is a design failure. A good plant layout design leaves ample space around major equipment. It includes permanent platforms, stairs, and ladders for access to key inspection points. Critically, it incorporates built-in lifting points or monorails above heavy components like mill rollers or large motors, turning a multi-day shutdown into a single-shift job. This proactive design saves enormous amounts of money and improves safety over the plant’s lifetime.

| Design Principle | The Goal | The Action |

|---|---|---|

| Logical Flow | Minimize material handling | Arrange equipment in a linear process sequence. |

| Use Gravity | Reduce energy and equipment costs | Place silos and bins to allow gravity discharge. |

| Plan for Maintenance | Reduce downtime and improve safety | Leave clear space and add access platforms/cranes. |

| Future-Proof | Allow for easy expansion | Leave open space for a second production line. |

Every design choice is also a financial choice. You must balance the upfront capital expenditure (CAPEX) with the long-term operational expenditure (OPEX) to achieve the best return on your investment.

A design using high-efficiency equipment like a vertical roller mill may have a higher initial investment, but it will have significantly lower long-term operating costs due to lower energy and maintenance needs. The cheapest design is rarely the most profitable.

A successful design is one that delivers the lowest total cost per ton of product over the life of the plant.

Understanding the trade-offs between different design philosophies is key to a profitable project.

This design philosophy prioritizes minimizing the upfront cost. It might use older, less efficient technology like a ball mill with a separate gypsum dryer, and a less sophisticated control system. While the initial purchase price is lower, the long-term costs are much higher. The energy consumption analysis will show higher electricity and fuel bills. Maintenance costs will be greater, and the lack of advanced automation may lead to lower product consistency and more downtime. This approach can be suitable for very small plants or markets where energy is extremely cheap.

This design focuses on minimizing the long-term operating cost. It uses modern, integrated technology like a vertical roller mill that combines grinding and drying. It invests in a comprehensive automation system to optimize the process and reduce labor needs. The initial investment is higher, but the payoff comes every single day in the form of lower energy bills, fewer breakdowns, and more consistent product quality. For any medium to large-scale project, this approach almost always delivers a superior long-term return on investment.

| Design Approach | Initial Investment (CAPEX) | Operating Cost (OPEX) | Long-Term Profitability |

|---|---|---|---|

| Low CAPEX | Lower | Higher (Energy, Labor, Maintenance) | Lower |

| High-Efficiency (Low OPEX) | Higher | Lower (High efficiency, Automation) | Higher |

Designing a successful gypsum grinding plant is a systematic process. It begins with a clear understanding of your product and raw material and flows through to a detailed, integrated design of all subsystems. By focusing on a systems-level approach, planning for quality and efficiency from the start, and balancing initial costs with long-term performance, you lay the foundation for a highly profitable and reliable operation.