全站搜索

Search the entire website

Search the entire website

Sawdust dryer has high drying intensity, short drying time, large production capacity, high efficiency, small occupied area, easy operation and maintenance, etc. It is also known as sawdust drying machine or sawdust rotary dryer.

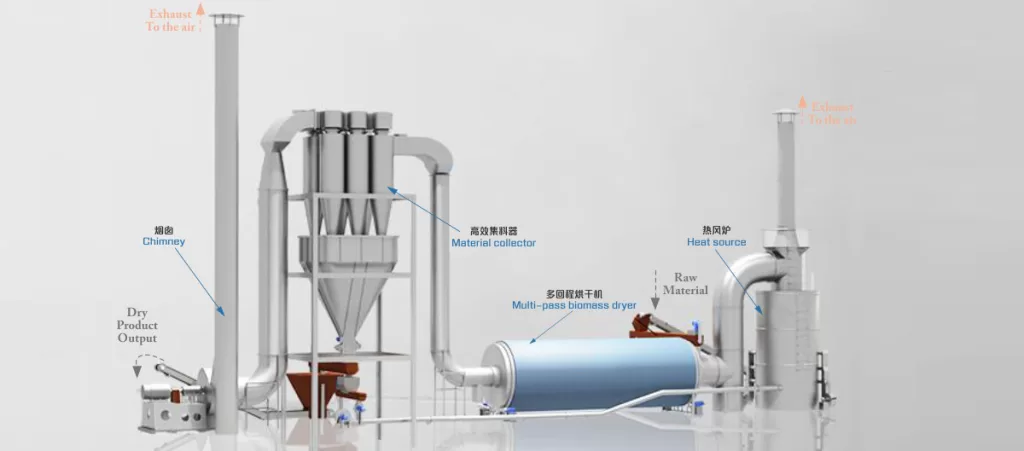

Sawdust dryer is suitable for drying powder/particle/shaving type wet sawdust materials. Sawdust materials are fed to dryer through screw conveyor. Under the fast conveying and scattering of hot air, moisture in wet materials is evaporate quickly and powder/particle final products are produced. Sawdust dryer mainly contains hot air furnace, feeding inlet, rotary drum dryr, pulse bag filter, material conveyor and induced draft fan.

Investing in a wood chip dryer transforms low-value or waste wood chips into valuable fuel or manufacturing feedstock. It drastically cuts disposal costs, generates revenue streams, improves material handling, and optimizes energy utilization.

Turning wood waste into treasure is the core function of a wood chip dryer. Here’s how it adds tangible value:

Consider fuel availability and long-term cost, capital investment for the heating system, required temperature control precision, emissions regulations, operational complexity, and integration with existing plant utilities (like steam availability).

Selecting the right heat source is a critical decision impacting both the initial investment and ongoing operating costs of your wood chip drying system. Key factors include:

The best choice often depends on local economics and existing infrastructure. ZONEDING can help evaluate these factors and integrate the most suitable heat source for your specific wood chip drying needs.

A wood chip dryer doesn’t operate in isolation. It needs several supporting machines to function correctly. Knowing all the parts helps in planning installation, space, and ensuring smooth operation from start to finish.

A complete system includes: Feed handling (hopper, screen, conveyor, feeder), the dryer unit itself, a heat source (burner/furnace/air heater), hot gas/air ducting, dust collection (cyclone/baghouse), exhaust fan, dried product discharge (cooling conveyor, storage), and a control system with safety interlocks.

A fully functional wood chip drying plant is an integrated system. While the dryer is central, several other pieces are essential:

High Mechanical Level and Large Capacity

New type sawdust dryer adpopts automatic electrical centralized control and can run continuously. Materials scatter uniformly in dryer drum so that wet material fully contact with hot air and drying effect is good.

Simple Structure Easy Operation Long Service Life

Whole sawdust drying system holds reasonble design. Relying on smooth drying process, sawdust can be dried fast in dryer drum. By adopting heat-resistant steel plate and stainless steel texture, sawdust dryer is featured in long service life and low malfunction rate.

Low Energy Consumption and Good Final Product Quality

Sawdust dryer adopts multi pass structure which makes heat can be utilized layer by layer. Energy consumption is lower than traditional dryer and drying effect is superior. Customers can recover equipment investment cost quickly.

Flexible Configuration and Wide Application Range

Whole drying system can be configured with feeding, heat source, conveying, dust collecting, discharging and packing system based on customer’s requirements. It can be widely applied to fullfill different drying demands so that each customer can find suitable drying equipment.

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Installation Obliquity(%) | Highest Inlet Air Temperature(℃) | Main Motor (kw) | Weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9~2.4 | 3~5 | 700~800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4~3.0 | 3~5 | 700~800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5~5.7 | 3~5 | 700~800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3~6.6 | 3~5 | 700~800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7~7.1 | 3~5 | 700~800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5~8.1 | 3~5 | 700~800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6~9.5 | 3~5 | 700~800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7~12.2 | 3~5 | 700~800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4~14.2 | 3~5 | 700~800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0~16.2 | 3~5 | 700~800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5~16.9 | 3~5 | 700~800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4~21.7 | 3~5 | 700~800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3~24.1 | 3~5 | 700~800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2~26.5 | 3~5 | 700~800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2~34.0 | 3~5 | 700~800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1~37.7 | 3~5 | 700~800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7~47.1 | 3~5 | 700~800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9~53.6 | 3~5 | 700~800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8~76.0 | 3~5 | 700~800 | 160 | 135 |

A sawdust dryer is industrial equipment that uses hot air to reduce the moisture content of sawdust and wood chips. This is vital for producing high-quality biomass pellets and briquettes. Creates high-energy fuel.

Drying sawdust significantly increases its calorific (heating) value, prevents mold, and ensures stable, high-density pellet formation. It also reduces smoke and improves combustion efficiency in boilers. Maximizes energy output.

Common sawdust dryer types include rotary drum dryers for large capacities and airflow or flash dryers for smaller particles. The choice depends on your required throughput and initial moisture levels. Provides scalable solutions.

Modern sawdust dryers feature temperature controls, spark detection, and rapid heat dissipation systems to prevent fires. Efficient design ensures uniform drying, minimizing the risk of overheating and combustion. Enhances operational safety.