全站搜索

Search the entire website

Search the entire website

This guide provides a comprehensive look at jaw crushers, covering everything from their core mechanics and common uses to the latest advancements and essential selection criteria, equipping you with the knowledge to leverage this technology effectively in the years to come.

The Jaw Crusher is the backbone of the crushing industry. At my company, ZONEDING, we consider it the most important machine in any quarry or recycling operation. It is a primary crusher, which means it does the heavy lifting. It takes the largest rocks from a blast or demolition site and breaks them into a manageable size. Think of it as a giant mechanical nutcracker for stone.

A jaw crusher is used for primary crushing. Its main job is to reduce large, tough materials into smaller pieces. This is the first step in most crushing processes. After the jaw crusher, the smaller rocks are sent to secondary crushers, like cone or impact crushers, for further processing. You need a jaw crusher to handle the biggest and hardest materials right from the start.

It creates a consistent feed for the rest of the plant. This makes the entire operation more efficient. Without a reliable primary crusher, your whole production line stops.

Every machine has its strengths and weaknesses. Understanding them helps you make the right choice.

Advantages:

Disadvantages:

You will find a jaw crusher in almost any industry that needs to break down large, hard materials. It is a true workhorse.

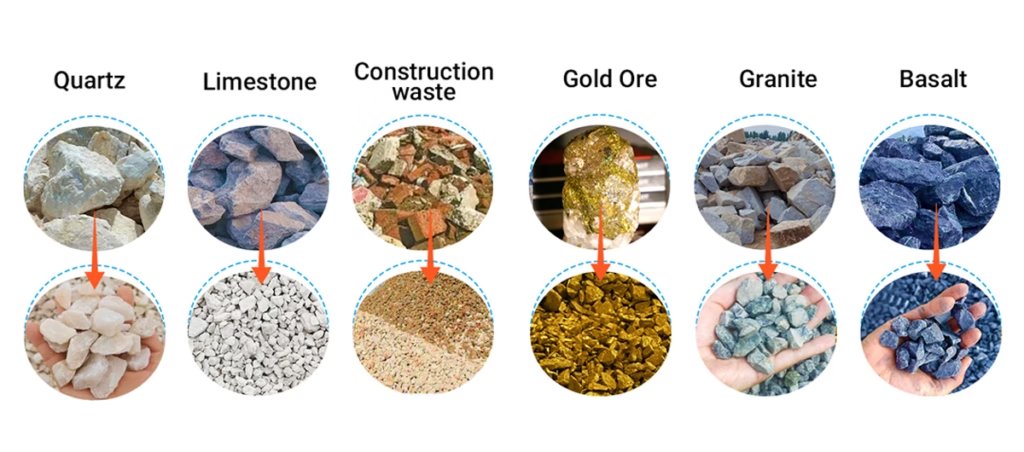

Jaw crushers are designed for the toughest jobs. They can handle a wide variety of hard and abrasive materials.

There are two main types of jaw crushers, based on how the swing jaw moves.

At ZONEDING, most of the crushers we build are Blake-type, as they are more reliable for heavy-duty primary crushing.

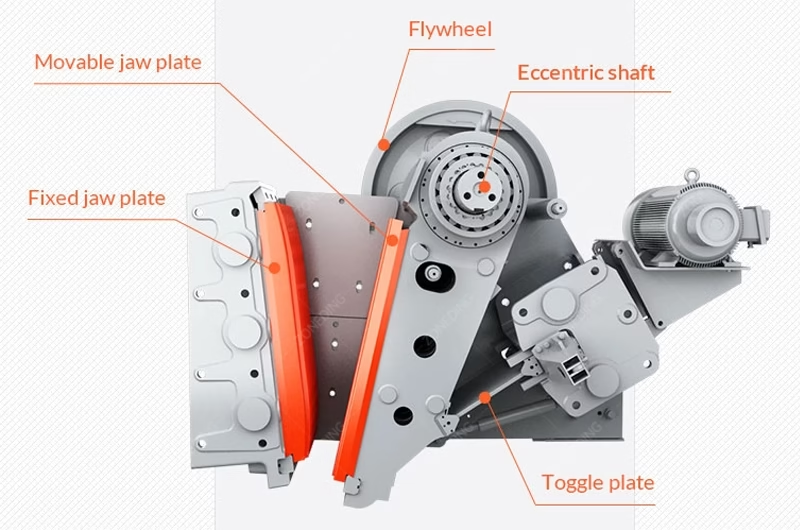

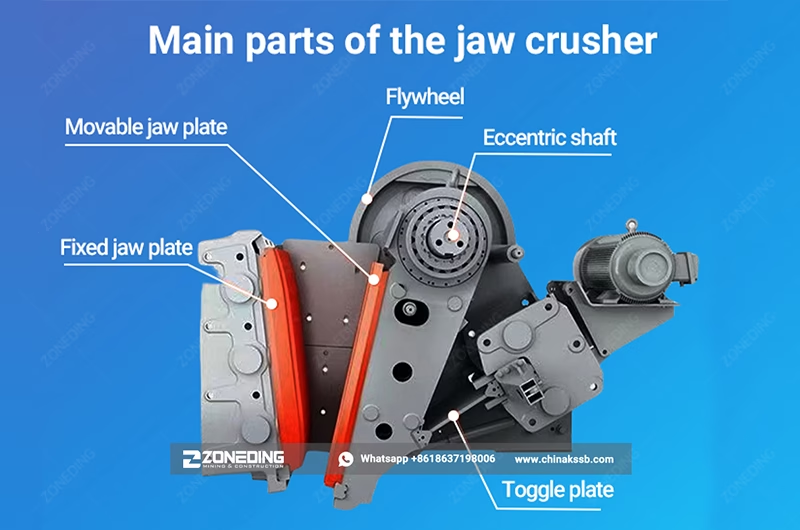

Understanding the main parts helps with operation and maintenance.

The jaw crusher working principle is simple but very effective.

A jaw crusher is just the beginning. A complete Crushing process solution involves multiple stages.

ZONEDING can design and supply these complete crushing plants for any application.

Choosing the right jaw crusher for sale is critical. Here is what you need to consider:

The jaw crusher price varies widely.

The price depends on size, brand, quality of components (like bearings and steel), and any extra features. As a direct manufacturer, we offer competitive pricing by eliminating the middleman.

The output size is controlled by the gap at the bottom of the crushing chamber. This is called the Closed Side Setting (CSS). It is the narrowest distance between the two jaw plates. The CSS determines the maximum size of the product that comes out. For example, with a CSS of 4 inches, most of the material will be smaller than 4 inches.

Proper jaw crusher maintenance is the key to a long and productive life.

A mobile jaw crusher is a complete primary crushing unit mounted on tracks or wheels. It includes the crusher, a feeder, a discharge conveyor, and a power unit. The biggest advantage is flexibility. You can move it directly to the material, saving a huge amount on hauling costs. They are very popular for contract crushing and recycling jobs.

The jaw crusher is an old design, but it continues to improve.

How long do jaw crusher plates last?

This depends entirely on the material being crushed. In soft limestone, they might last for thousands of hours. In hard, abrasive granite or river gravel, they might need to be replaced after only a few hundred hours.

Can a jaw crusher handle wet and sticky material?

It can be a problem. Wet, sticky material like clay can pack in the V-shaped chamber and cause blockages. A special “slab-breaker” jaw plate design can help, but it is not ideal. A different type of feeder might be needed.

The jaw crusher is the essential starting point for almost any crushing operation. It is a simple, powerful, and reliable machine designed to handle the toughest jobs. Choosing the right one depends on your material, feed size, and capacity needs. Proper operation and consistent jaw crusher maintenance will ensure it remains a profitable workhorse for your business for many years.

If you are looking for a new stone crusher or need advice on your current operation, our team at ZONEDING is here to help. Contact us today for a free consultation and let our experience work for you.

The crushing process is the heart of turning large, unusable rock into valuable, specific-sized products like sand and gravel. The goal of any rock crushing plant is to reduce the size of raw material through a series of stages to produce aggrega...

View detailsYou see quartz every day, but you probably do not recognize it. It is in the glass of your phone screen and the windows of your house. It is even in the countertop in your kitchen. Raw quartz stone from the ground is not ready for these jobs. It ...

View detailsFacing a choice between a ball mill and a rod mill? Feeling confused? It's very important to select the right grinding equipment. Ball mills and rod mills are both grinding equipment, but they differ in grinding media, mechanism, product size, ...

View detailsAre you watching your profits wash away with your wastewater? In many sand washing plants, a significant amount of fine sand (75 microns / 200 mesh and smaller) escapes with the overflow water. This isn't just waste; it's lost product and lost re...

View details