Are you watching your profits wash away with your wastewater? In many sand washing plants, a significant amount of fine sand (75 microns / 200 mesh and smaller) escapes with the overflow water. This isn’t just waste; it’s lost product and lost revenue. A hydrocyclone separator is a simple, powerful machine designed to solve this exact problem. It recovers valuable fine sand, improves your final product quality, and significantly boosts your sand plant efficiency. At ZONEDING, we help our clients turn this common waste stream into a consistent profit center.

Table of Contents

Why is Fine Sand Recovery So Critical?

Losing fine sand is a bigger problem than you might think. First, it’s a direct financial loss. You are throwing away a saleable product. Second, it ruins your sand’s grading. High-quality concrete requires a specific mix of coarse and fine particles for maximum strength and workability. Without enough fines, your sand fails to meet specifications and sells for a lower price. Third, it creates an environmental problem. Your settling ponds fill up with sediment quickly, requiring expensive and frequent cleanouts. Fine sand recovery solves all three issues at once.

What is a Hydrocyclone?

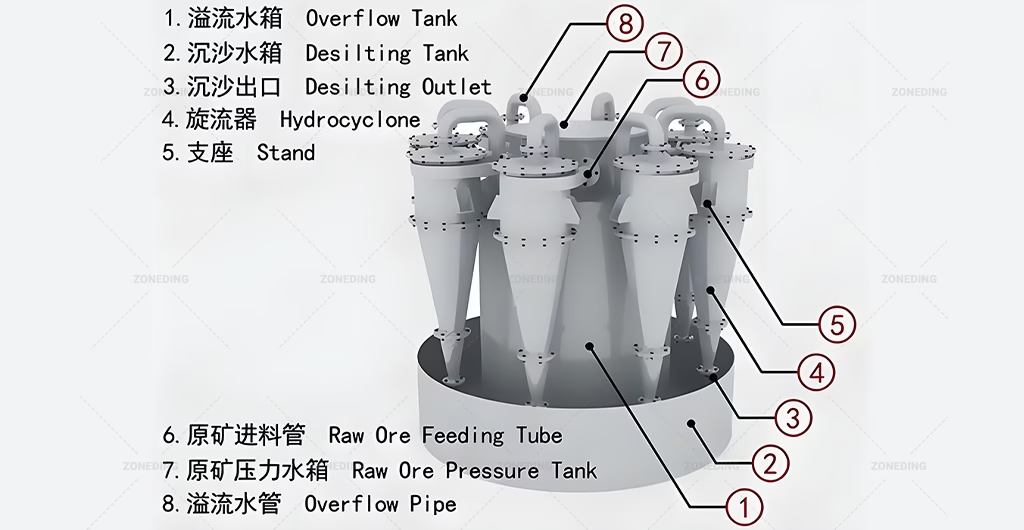

A hydrocyclone separator is a machine that uses centrifugal force to separate particles in a liquid slurry. The most surprising thing about it is that it has no moving parts. It’s essentially a cone-shaped chamber. A slurry of water and sand is pumped into it at high pressure, and the physics of the spinning fluid does all the work. It separates the heavier, coarser sand particles from the lighter, ultra-fine particles and water. It is a core component of any modern sand washing plant.

How Does a Hydrocyclone Separator Actually Work?

The sand cyclone separator working principle is simple but very effective. Here is the process step by step:

- Feed: A powerful slurry pump feeds the mixture of water and sand into the hydrocyclone through an inlet at the top. The inlet is tangential, meaning it forces the slurry to enter in a spiral pattern.

- Vortex Creation: This tangential entry creates a powerful, fast-spinning vortex, similar to a whirlpool or a tornado. This generates immense centrifugal force.

- Separation: The centrifugal force throws the heavier, coarser sand particles to the outside wall of the cone. They spiral down the wall and exit through a small opening at the bottom called the spigot or underflow.

- Overflow: The lighter, ultra-fine particles and the bulk of the water are less affected by the force. They are drawn up through the center of the vortex and exit through a pipe at the top, called the vortex finder or overflow. This overflow water is now much cleaner and can be recycled.

What is the Cost of Hydrocyclones Separators?

The cost for a single hydrocyclone unit can range from $200 to over $20,000. However, the cyclone itself is just one part of a complete system. A full fine sand recovery module, including the cyclone, a slurry pump, a motor, a collection tank (sump), and the interconnecting pipes, will have a different price point. A complete system integrated with a dewatering screen represents the most effective solution and will be a larger investment. The hydrocyclone for sand washing price depends entirely on the scale and completeness of the system you need.

What Factors Influence the Price of Hydrocyclones Separators?

Several key factors determine the final price of a hydrocyclone system. It is important to look beyond just the sticker price.

- Capacity (Size): A larger diameter cyclone can process a higher flow rate (m³/h) and tonnage, and will naturally cost more.

- Liner Material: This is the most critical factor for operational cost. The inside of the cyclone is lined with a wear-resistant material. Low-cost options use rubber, but professional-grade cyclones from ZONEDING use high-wear polyurethane or even ceramic liners, which last much longer and justify their higher initial cost.

- Pump and Motor Quality: The slurry pump does all the work. A high-quality, abrasion-resistant pump is essential for reliable performance and long life.

- Steel Thickness: A robust steel housing is needed to withstand the pressure and vibration of the system.

How to Choose the Right Hydrocyclones Separators?

Choosing the right hydrocyclone is about matching the machine to your specific material and goals. Here are the steps you should follow:

- Analyze Your Waste Stream: First, you need to know what you are losing. Take samples of your overflow water and determine the percentage and particle size of the sand you are losing.

- Define Your Target: What is the cutoff point? Do you want to recover everything down to 150 microns or 75 microns? This will determine the size and operating pressure of the cyclone.

- Calculate Required Capacity: Determine the total flow rate (in cubic meters per hour or gallons per minute) of your wash water that needs to be processed.

- Think System, Not Component: Remember, you are buying a system. Ensure your supplier can provide a properly matched slurry pump and, ideally, a dewatering screen to receive the recovered sand. The screen is vital for producing a final, dewatered product that is immediately conveyable and saleable.

What are Features of Hydrocyclones from ZONEDING?

At ZONEDING, we design our hydrocyclone systems for maximum efficiency and minimum downtime.

- High-Wear Polyurethane Liners: We use specially formulated, centrifugally cast polyurethane for our liners. This provides superior resistance to abrasion compared to standard rubber, meaning longer life and less maintenance for you.

- Optimized Geometric Design: The exact angles of the cone and the dimensions of the inlet and vortex finder are critical. Our designs are computer-modeled and field-tested to create a sharper separation, meaning less good sand is lost to the overflow.

- Complete System Integration: We don’t just sell you a cyclone. We provide a complete, skid-mounted system with a perfectly matched slurry pump and a robust dewatering screen. Our systems are plug-and-play, designed to be easily integrated into your existing sand washing machine setup.

How to Choose the Right Supplier for Hydrocyclones?

When selecting a supplier, you should look for a partner, not just a vendor.

- Technical Expertise: Can they help you analyze your sand and recommend the right size and pressure? Or are they just reading from a catalog?

- System Design Capability: Do they understand how the cyclone, pump, and screen must work together? Ask to see designs of their complete systems.

- Wear Parts Availability: How quickly can you get replacement liners or pump impellers? A cheap machine with no parts support is a terrible investment.

- Proven Case Studies: Ask for real-world examples of how their systems have improved other sand plants. A reputable supplier will be happy to share their success stories.

Since 1990, ZONEDING has been a direct manufacturer of high-performance aggregate processing equipment. We have delivered complete solutions to over 120 countries. And we don’t just sell machines; we design and build integrated systems.

By manufacturing directly, we control the quality of every component, from the polyurethane formula in our liners to the grade of steel in our frames. This factory-direct model allows us to provide superior technology and expert support at a more competitive price. Our engineers are ready to help you design a fine sand recovery system that is perfectly tailored to your needs.

FAQ

- Can This Hydrocyclone Machine Really Improve Your Final Sand Quality?

Yes, absolutely. By recovering the fine particles, you can blend them back into your coarse sand to create a product with an ideal grading curve. This well-graded sand is more valuable because it produces stronger, more workable concrete with less cement, saving your customers money.

- What are the Core Components of a Complete Fines Recovery System?

A complete system consists of more than just the cyclone. The core components are: 1) A sump or tank to collect the slurry. 2) A high-wear slurry pump to feed the cyclone. 3) The hydrocyclone separator itself. 4) A high-frequency dewatering screen to receive the underflow and produce a drip-free, stackable final product.

- What are the Main Maintenance Points for a Hydrocyclone System?

The main points are all related to wear. You need to regularly inspect the cyclone’s internal liner and the spigot for wear, as this affects separation efficiency. You also need to check the impeller and liner of the slurry pump, as this is a high-wear area.

- What percentage of fine sand can a hydrocyclone recover?

A well-designed and properly operated hydrocyclone system can be very efficient. It can typically recover up to 95% of the sand particles larger than 75 microns (200 mesh) from the wash water, dramatically reducing waste.

- Can a hydrocyclone work with any type of sand?

Yes, the principle works with virtually any type of sand, including natural sand, manufactured sand, and silica sand. The system’s performance is simply tuned—by adjusting operating pressure and spigot size—to match the specific particle size distribution and density of your material.

Summary and Final Advice

A hydrocyclone separator is not a cost; it’s an investment with a rapid return. It stops the loss of valuable product, improves the quality and value of your final sand, and reduces your environmental and maintenance burdens. The key is to view it as a complete system—pump, cyclone, and dewatering screen—working together. By choosing a supplier who understands this system-based approach, you can transform your plant’s profitability.

Your next step is to quantify your losses. Take a sample of your overflow water and see exactly what you are throwing away. Then, contact an expert to discuss how a properly designed recovery system can turn that waste back into profit.