全站搜索

Search the entire website

Search the entire website

For every nugget that makes headlines, there are millions of ounces of gold that go unnoticed, washing out the back of sluice boxes or floating over the lip of a pan. This is “flour gold”—particles so fine they resemble dust. In many geological deposits, particularly glacial tills and downstream placers, flour gold represents 90% to 95% of the total value in the ground. Yet, for inexperienced miners and prospectors, it is the most frustrating material to process.

The problem is physics. While gold is dense (Specific Gravity 19.3), flour gold particles are so small and flat that surface tension can make them float like a dry leaf on a pond. When this happens, the gold is lost, returning to the riverbed along with the miner’s potential profits. Recovering this “ghost gold” requires a shift in strategy. It demands precise classification, the chemical alteration of water tension, and fine-tuned mechanical separation. This guide outlines the definitive methods for capturing the microscopic wealth that others leave behind.

Last Updated: January 2025 | Estimated Reading Time: 16 Minutes

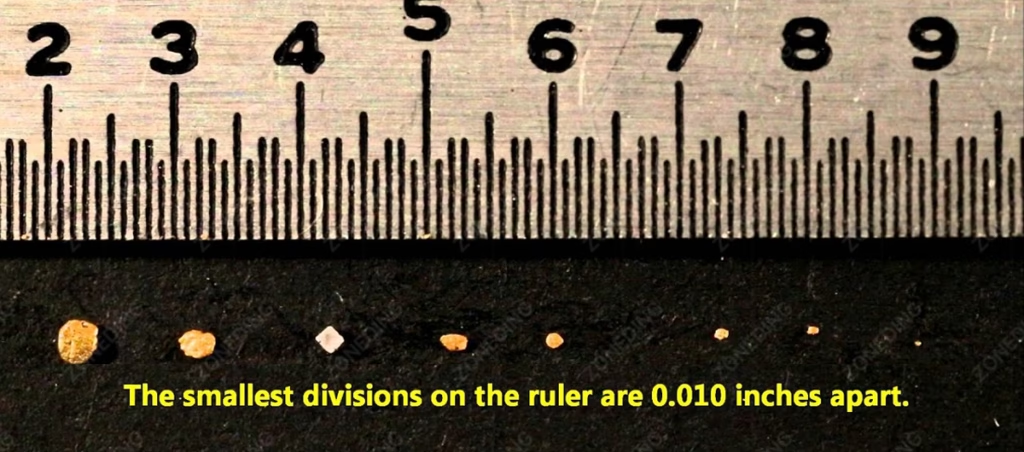

Before attempting to recover it, a miner must first identify exactly what “flour gold” is. In the mining industry, flour gold (also known as “gold dust” or “flood gold”) refers to extremely fine particles of gold handled in bulk. Unlike nuggets or “pickers”—which can be easily moved with fingers or tweezers—flour gold is microscopic, often resembling the texture of baking flour or fine face powder.

Geologically, flour gold is not a distinct type of element; it is simply chemically pure gold that has been pulverized by glacial action or eroded over millennia of river transport. In technical processing terms, it is defined by its ability to pass through specific mesh screens.

To catch flour gold, one must first understand why it behaves differently than a nugget. Gravity separation relies on the principle that gold is 19 times heavier than water and roughly 7 times heavier than the surrounding gravel. In a vacuum, a piece of gold will always drop faster than a piece of quartz.

However, mining does not happen in a vacuum; it happens in water.

If a miner sees gold dust floating in the corner of their pan, it is not an illusion. It is a physics failure that requires immediate correction.

The single biggest mistake in fine gold recovery is skipping classification. Classification is the process of separating material by size using screens or sieves.

In a sluice box or a pan, gold sinks because the material is agitated, allowing heavy particles to migrate to the bottom. If a miner tries to process fine dust alongside large rocks (e.g., walnut-sized gravel), the large rocks create turbulence. This turbulence acts like a violent storm, kicking the tiny gold particles back up into the water flow where they are washed away.

To catch flour gold, the feed material must be screened to a uniform size.

When material is screened to #50 mesh (roughly the size of table salt), the water flow can be reduced drastically. Low-pressure, laminar water flow allows the tiny gold particles to settle without being blasted out by the turbulence of larger rocks.

When processing concentrates—the black sand and gold mix left at the end of the day—surface tension is the enemy. This is where modern chemistry aids ancient mining.

“Jet Dry” is a brand name for a rinse aid used in dishwashers to prevent water spots. Technically, it is a surfactant (surface active agent). Prospectors have adopted it as a secret weapon.

Panning for nuggets involves aggressive shaking to get the big rocks out. Panning for flour gold is a delicate art that resembles surgery more than excavation.

When finishing a batch of fine concentrates, never pan directly into the river. Always pan into a “safety tub” or a larger plastic bin. This catches any accidents. If the gold is lost from the pan, it remains in the tub to be processed again later.

While panning is excellent for testing and final cleanup of small batches, it captures zero income. To make money from flour gold, miners need continuous throughput. This requires specialized industrial equipment designed to mimic the physics of the pan but at 100 times the speed.

Old-school miners used carpet or “miner’s moss.” While effective for coarse gold, these mats often pack up with black sand, creating a smooth surface that flour gold slides right over.

For commercial operations aiming to recover micron-sized gold (-100 mesh), gravity alone is often too slow. The solution is to artificially increase gravity.

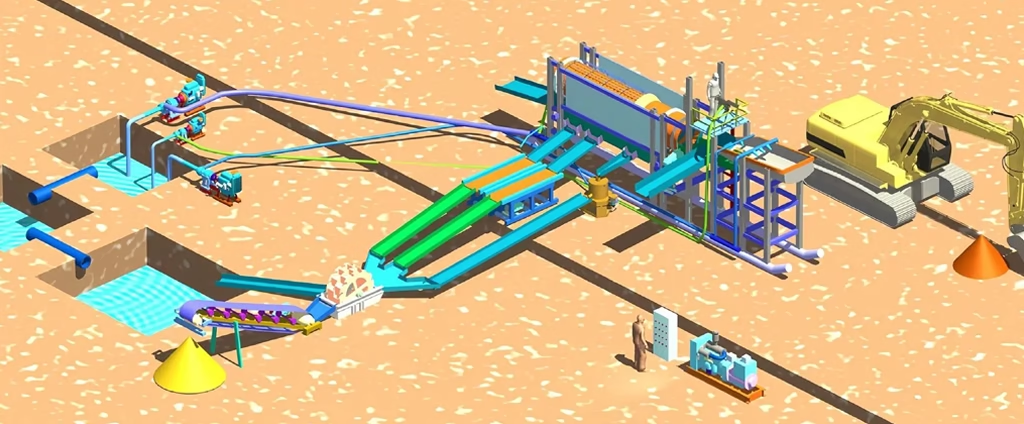

ZONEDING Centrifugal Concentrators (similar to Knelson or Falcon concentrators) spin the ore slurry at high speeds, generating 60G to 80G of force.

Once a miner has reduced tons of river gravel down to a bucket of black sand and flour gold, the final separation occurs on a Shaking Table.

| Feature | Sluice Box | Centrifugal Concentrator | Shaking Table |

|---|---|---|---|

| G-Force | 1 G | 60 – 80 G | 1 G + Vibration |

| Feed Size | Coarse to Fine | Fine (< 2mm) | Fine (< 2mm) |

| Recovery Size | > 50 mesh | > 400 mesh (Micron) | > 200 mesh |

| Primary Use | High Volume / Roughing | Scavenging Fines | Final Cleanup / Upgrade |

The most common error in running fine gold equipment (like the ZONEDING Spiral Chute or Shaking Table) is using too much water. Fine gold is easily blown away. The water should be a thin film, barely covering the sand. If the water is turbulent or “white,” it is too fast.

Clay creates a thick, viscous slurry that holds onto gold particles, preventing them from sinking. If the deposit has heavy clay, a Log Washer or Trommel Scrubber is mandatory before the material ever hits the recovery circuit. These machines scrub the rocks, dissolving the clay into a liquid that can be washed away, leaving the gold free to settle.

Historically, miners used mercury (amalgamation) to catch flour gold because mercury binds to gold on contact.

Catching flour gold is not about luck; it is about engineering. The miner who relies solely on a shovel and a hopeful attitude will leave the majority of their wealth in the tailings pile.

The path to profitability in fine gold recovery follows a strict hierarchy:

Why Choose ZONEDING for Fine Gold Recovery?

ZONEDING understands that in modern mining, the profit is in the details. The days of stumbling upon fist-sized nuggets are largely over. Today’s mine is a factory that processes volume. ZONEDING provides the complete flowchart—from Trommel Screens for washing clay to High-G Centrifuges and 6-S Shaking Tables for final capture.

Stop letting the river take your salary.

Contact ZONEDING today to design a fine gold recovery circuit that turns dust into deliverable bars.

Last Updated: January 2026

Discover 5 strategies to turn tailings and waste rock into profitable assets, from recovering critical minerals to creating green construction materials.

View detailsExplore a balanced analysis of Cyanide leaching method for gold extraction, including its concepts, benefits and concerns, and solutions.

View detailsLearn the list of the top 10 most precious metals. Understand their critical uses, market value, and the scientific reasons behind their exceptional scarcity.

View detailsFrom primary crushing to screening. We analyze the 9 kinds of machinery needed to build a stone crushing plant. Learn their function to optimize your circuit.

View details