全站搜索

Search the entire website

Search the entire website

Is the stone crushing business actually profitable in the current economic climate? This remains one of the most frequent questions posed by investors and contractors looking to diversify their portfolios. The short answer is a resounding “yes,” but with a major caveat: profitability depends entirely on operational efficiency and equipment selection. As global infrastructure projects boom—from highway expansion to rapid urbanization—the demand for aggregate (sand, gravel, and crushed stone) has never been higher.

However, viewing this industry as a “get rich quick” scheme is a mistake. It is a capital-intensive heavy industry that rewards strategic planning and punishes inefficiency. Choosing the wrong crusher for a specific stone type or mismanaging logistics will cause margins to vanish. This guide examines the financial realities, the secrets to minimizing wear costs, and how ZONEDING helps clients worldwide turn raw rock into reliable revenue.

Before investing capital, understanding the market forces driving demand is crucial. Why is there such a substantial need for crushed stone?

Every physical structure requires aggregate. A single kilometer of highway requires tens of thousands of tons of base material. Residential high-rises, bridges, and dams all rely on concrete, and concrete is 60-75% aggregate by volume. As developing nations improve their infrastructure and developed nations repair theirs, the hunger for crushed stone remains insatiable.

River sand resources are depleting, and environmental regulations are tightening globally to ban river dredging. This has created a massive vacuum in the market for “Manufactured Sand” (M-Sand). By using a Vertical Shaft Impact (VSI) crusher, low-value waste rock can be turned into high-value engineered sand, often selling at a premium compared to natural sources.

| Market Driver | Description | Impact on Business |

|---|---|---|

| Urbanization | Rapid expansion of cities requiring cement and roads. | Consistent local demand for 10-20mm aggregate. |

| Environmental Policy | Bans on natural river sand mining. | Massive opportunity for Crusher Dust and M-Sand. |

| Recycling Trends | Processing construction waste (concrete/bricks). | New revenue streams using Mobile Crushers. |

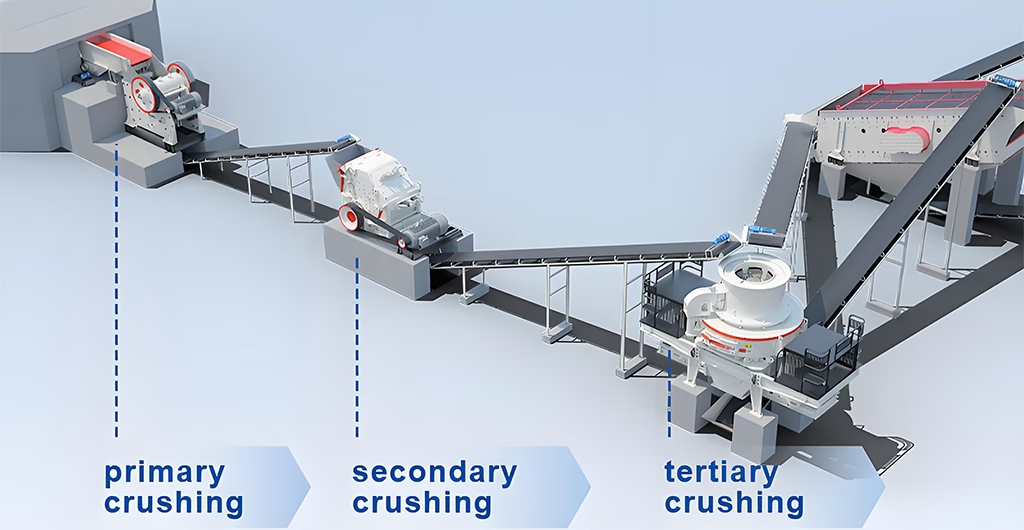

This is where a business either succeeds or bleeds money. The crushing circuit is the heart of the operation. Selecting a machine that is too small bottlenecks production; selecting one that is too large wastes electricity.

For the first stage of reduction, dealing with large blasted boulders (500mm to 1000mm), there are generally two choices:

Once the rock is reduced to a manageable size (e.g., 150mm), it must be shaped and sized.

This is a critical decision based on site tenure.

Many newcomers calculate profit simply: Sale Price of Stone – Cost of Explosives – Fuel. This is dangerous math. To run a profitable stone crushing business, mastering the hidden costs is essential.

This is the single biggest variable. Every time the crusher hits a rock, metal is removed from the liner.

Stone is heavy and cheap. It cannot be transported far before the freight cost exceeds the material value.

In this business, if the belt isn’t moving, money is being lost.

When ready to buy, how is a partner chosen? It is not just about the lowest price tag on the machine; it is about the “Total Cost of Ownership.”

As a manufacturer, ZONEDING cuts out the trading company middleman.

Building a plant requires coordinating feeders, crushers, screens, belts, and electric control panels.

So, is the stone crushing business a profitable investment? Yes. It is a foundational industry that supports civilization’s growth. The demand for aggregate is not going away. However, the margin for error is slim. Profitability comes from:

For those ready to transform raw stone into a solid revenue stream, avoid guessing through the setup. ZONEDING can assist in calculating potential capacity and ROI.

Ready to build a plant?

Contact ZONEDING today for a free consultation and customized plant design proposal.

Last Updated: January 2026

This guide tells what mineral processing is, explaining how valuable materials are extracted through essential steps like crushing, grinding, and separation.

View detailsThis guide covers the essential stages: crushing, grinding, and various beneficiation methods like gravity separation, magnetic separation, and flotation.

View detailsUnderstand dry grinding process: definition, workprinciple, advantages, and common applications in various industries. Get a complete overview here.

View detailsWe clearly explain what andalusite is, its thermal properties, and the essential steps used to process it for applications in steel, ceramics, and foundries.

View details