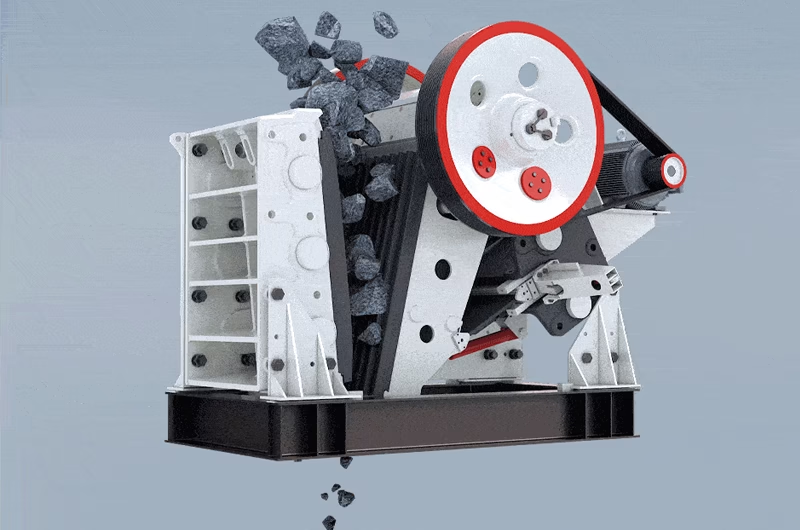

Your jaw crusher is the workhorse of your entire operation. When it runs well, your business is productive. But when it has problems, everything stops. My company, ZONEDING, has been manufacturing heavy-duty crushing equipment since 1990. We have seen every possible issue a jaw crusher can have. This guide shares our 30+ years of experience in jaw crusher troubleshooting. We will explain the most frequent jaw crusher problems and show you exactly how to fix your jaw crusher quickly and safely, so you can minimize downtime and protect your profits.

Table of Contents

Why is it Important to Maintain Jaw Crushers?

Proper jaw crusher maintenance is the single most important factor for profitability and safety. Think of your crusher like a car. If you never change the oil or check the tires, you will eventually have a very expensive breakdown on the highway. A jaw crusher is the same. Small, consistent checks prevent catastrophic failures. Regular maintenance ensures the machine runs efficiently, producing the correct size of aggregate at the highest possible capacity.

Beyond production, safety is a huge reason. A poorly maintained crusher can be very dangerous. A component failure under the immense pressure of crushing rock can cause serious accidents. At ZONEDING, we design our crushers for easy and safe maintenance, but this design only works if you follow a regular schedule. A few minutes of inspection each day can save you thousands of dollars in repairs and, more importantly, can prevent injuries on your site. Neglecting maintenance is not a cost-saving measure; it is an expensive risk.

Jaw Crushers 7 Common Problems and Reasons? How to Fix?

Over our many years in business, we have seen that most breakdowns are caused by one of these seven common jaw crusher problems. Understanding the reason behind each problem is the key to finding the right solution. Here is our practical guide to jaw crusher troubleshooting.

1. The Bearing is Overheating

An overheating bearing is a critical warning. The normal jaw crusher bearing temperature limit is around 70-75°C (158-167°F). If it gets hotter, you must stop and investigate.

- Reasons: The most common cause is a lack of lubrication. The grease pump might be broken, a line could be blocked, or the wrong type of grease is being used. Dust and dirt can also get into the bearing, causing friction. Another reason is improper installation, where the bearing is either too tight or too loose on the shaft.

- How to Fix: First, check the lubrication system. Make sure grease is reaching the bearing. Then, confirm you are using the correct grease specified in your machine’s manual. If lubrication is fine, you may need to check the bearing seals for damage that could let dirt in. If the problem continues, the bearing may have been installed incorrectly and will need to be re-fitted by a qualified technician.

2. The Crushing Capacity is Too Low

Low output directly hurts your bottom line. If you are not producing the tons per hour you expect, it needs to be addressed.

- Reasons: The number one reason for low capacity is worn jaw plates. As the teeth wear down, they cannot grip the rock effectively. Another common cause is an incorrect Closed Side Setting (CSS). If the gap is too small, material can’t exit the chamber, choking the crusher. Slipping V-belts can also cause the crusher to run below its optimal speed.

- How to Fix: Inspect your jaw plates. If the teeth are worn flat, it is time to replace them. Use a tape measure to check the CSS and adjust it according to your product needs. Finally, check the tension of the V-belts and tighten them if they are slipping. These are some of the simplest jaw crusher low output solutions.

3. There are Unusual Noises or Vibrations

Your crusher has a normal operating sound. Any sudden change, like loud banging, grinding, or screeching, is a sign of trouble.

- Reasons: A loud bang often means a bolt has broken, or an uncrushable piece of metal (tramp iron) has entered the chamber. A grinding noise almost always points to a failing bearing. Excessive vibration can be caused by loose mounting bolts or a component that is out of balance.

- How to Fix: For any unusual noise, shut down the crusher immediately. Do a full visual inspection for loose or broken bolts, especially those holding the jaw plates. A grinding sound means you need to schedule a replacement of the failing bearing as soon as possible. Our guide on jaw crusher noise troubleshooting always starts with a safe shutdown and a careful inspection.

4. The Jaw Plates Wear Out Too Fast

Jaw plates are meant to be replaced, but they should not wear out in just a few weeks. If they do, your operational costs will be too high.

- Reasons: The quality of the manganese steel is the biggest factor. Cheaper plates wear out faster. Another issue is incorrect installation; a loose jaw plate will vibrate and wear very quickly. Also, feeding a lot of small, abrasive rock can cause concentrated wear at the bottom of the plates.

- How to Fix: Invest in high-quality jaw plates from a reputable supplier like ZONEDING. We use high-manganese steel (Mn18Cr2) for maximum life. Always use a torque wrench to tighten the bolts to the manufacturer’s specifications. If you can, use a screen to remove the small abrasive fines from the feed material before it enters the crusher.

5. The Final Product Size is Inconsistent

If your customers start complaining that your aggregate size is all over the place, you have a problem.

- Reasons: The most common cause is that the Closed Side Setting (CSS) has slipped and is now too wide. Another serious cause is a broken toggle plate. The toggle plate holds the bottom of the moving jaw in place, and if it breaks, you will lose all control over the product size.

- How to Fix: Make checking the CSS a part of your daily routine. If the setting is correct, inspect the toggle plate for any cracks or a complete break. A broken toggle plate must be replaced immediately.

6. The Crusher Stops When Under Load

A crusher that stalls while full of rock is a major headache.

- Reasons: The most frequent cause is a packed discharge chute. If the conveyor belt under the crusher is too slow or too small, the crushed rock will back up into the machine, packing it tight until it jams. It can also be an electrical issue, like a tripped motor breaker, or slipping V-belts that can’t transfer enough power.

- How to Fix: Ensure your discharge conveyor has enough capacity and is running properly. Never start a jaw crusher when there is rock in the chamber. Always clear the chamber before starting the machine. Check your motor and belts to ensure they are in good condition and properly tensioned.

7. The Toggle Plate Keeps Breaking

The toggle plate is a safety device. It is designed to break to protect the crusher from extreme damage. But it should not break often.

- Reasons: The main reason a toggle plate breaks is tramp iron (uncrushable metal) entering the crusher. It can also break if you try to run the crusher with a CSS that is too small for the machine’s design limits. Using a poor-quality, weak toggle plate can also cause frequent failures.

- How to Fix: The best solution is to install a powerful magnet over your feed belt to remove tramp iron. Always operate your crusher within its recommended CSS range. And only use high-quality toggle plates from the original manufacturer. A cheap toggle plate that breaks too easily offers no protection and one that is too strong can cause you to break a multi-thousand dollar frame.

Operation Requirements to Avoid Problems?

The best way to fix jaw crusher issues is to prevent them from happening. Proper operation is just as important as maintenance.

- Ensure “Choke Feeding”: A jaw crusher works most efficiently when the crushing chamber is kept about two-thirds full. This promotes rock-on-rock crushing, which is more efficient and produces a better product shape.

- No Starting Under Load: Never start the crusher with rock in the crushing chamber. This puts an incredible strain on the motor and all mechanical parts.

- Remove Fines Before Crushing: Small rocks and dirt (fines) do not need to be crushed. They just take up space in the chamber and cause unnecessary wear on the jaw plates. Use a vibrating grizzly feeder to remove them.

- Continuous and Stable Feeding: Do not dump huge loads of rock into the crusher all at once. Use a feeder to provide a steady, consistent flow of material.

How to Maintain and Check the Jaw Crushers Correctly?

A simple and consistent preventative maintenance for jaw crushers plan is your best tool for reliability.

- Daily Checks: Before starting up, do a quick walk-around. Look for any loose bolts, oil or grease leaks, and cracks in the frame. Listen for strange noises during startup and shutdown. Check the bearing temperature.

- Weekly Checks: Perform a more detailed inspection. Check the V-belt tension and condition. Check the wear on the jaw plates and measure the CSS to make sure it has not changed.

- Monthly Checks: Do a full inspection of the lubrication system. Check the condition of the toggle plate and its seats. Inspect the main frame for any signs of stress or cracking, especially around the welds.

What are Common Spare Parts on Jaw Crushers You Should Prepare?

Downtime is lost money. Having critical spare parts on hand can turn a week of downtime into just a few hours.

- Jaw Plates: This is the most common wear part. You should always have at least one full set (one fixed, one moving) in stock.

- Toggle Plate: Because this part is designed to break, it is essential to have one or two spares ready for a quick replacement.

- V-Belts: Belts can snap without warning. Having a replacement set is a cheap way to avoid a long shutdown.

- Main Bearings: A full set of pitman bearings is a larger investment, but a bearing failure can stop you for weeks if you have to wait for a new set to be delivered.

- Side Liners (Cheek Plates): These plates protect the sides of the crusher frame. They are much cheaper to replace than repairing the frame itself.

What is the Price of Spare Parts of Jaw Crushers?

The price of spare parts changes a lot depending on the part, the material quality, and the supplier. For example, a set of high-quality, high-manganese jaw plates for a medium-sized crusher could cost between $2,000 and $10,000. A single toggle plate might be between $500 and $2,500. Cheaper parts are available, but they often wear out much faster, costing you more in the long run. As a factory-direct manufacturer, we at ZONEDING cut out the middleman, offering competitive prices on high-quality parts that provide the best long-term value for your investment.

FAQ

- Which parts of jaw crushers need to be lubricated?

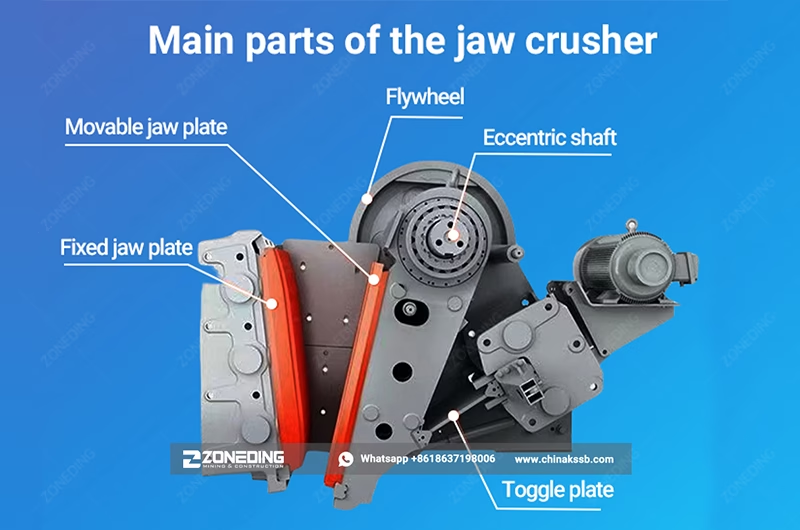

- The most critical parts are the main eccentric shaft bearings, often called pitman bearings. These high-load bearings require consistent and correct lubrication, usually with a high-pressure EP2 grease. Some older models may also have grease points for the toggle plate seats.

- How to tell when pitman bearings are bad on a jaw crusher?

- The first sign is usually overheating. You may also hear a rumbling or grinding noise, especially when the crusher is coasting to a stop. In advanced stages of failure, you might see excessive vibration or even find metal shavings in the grease.

- How to adjust the toggle plate of the jaw crusher?

- You do not adjust the toggle plate itself, but you use it to adjust the output size (CSS). On older machines, you change the CSS by adding or removing shims behind the toggle plate. On modern machines, like those from ZONEDING, this is done with a hydraulic system that moves the toggle block forward or backward with the push of a button.

Conclusion and Final Advice

Effective jaw crusher troubleshooting is not about waiting for a problem and then reacting. It is about understanding how the machine works and creating a system of operation and maintenance that prevents problems. The seven common issues we covered are responsible for over 90% of jaw crusher downtime. By teaching your team how to spot the early warning signs and how to perform routine checks, you can dramatically increase the reliability of your operation.

The best advice we can give is to be proactive.

- Train Your Operators: They are your first line of defense. Teach them what to look for and listen for.

- Stick to a Schedule: Create a simple maintenance checklist and make sure it is followed every single day.

- Use Quality Parts: Using high-quality spare parts from a trusted manufacturer will always save you money in the long run.