Gabbro is an incredibly tough and durable rock. It makes some of the best construction aggregate in the world. However, its toughness also makes it a challenge to process. My company, ZONEDING, has been designing and building crushing plants since 1990. We specialize in creating solutions for hard rocks like gabbro. The process of gabbro crushing turns this dark, heavy rock into a highly profitable product. This guide will show you exactly how to do it. We will cover everything from the basic properties of gabbro to designing an efficient and profitable gabbro crushing plant.

Table of Contents

What Exactly is Gabbro Rock?

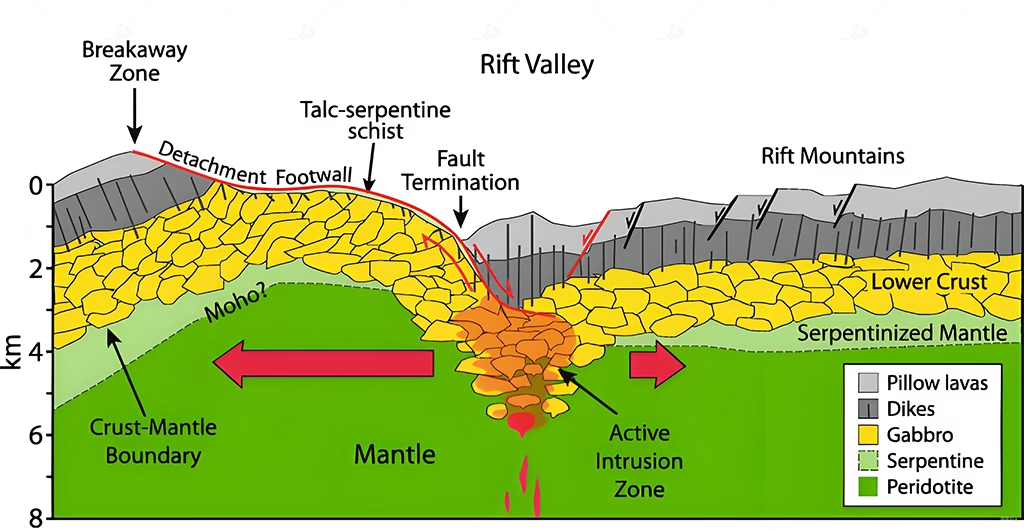

Gabbro is a type of igneous rock. It is coarse-grained and usually dark, often black or dark green in color. Think of it as the underground cousin of basalt. Basalt is lava that cools quickly on the surface, creating fine-grained rock. Gabbro is magma that cools very slowly deep within the Earth’s crust. This slow cooling process allows large, visible crystals to form, which gives the rock its incredible strength. It is a dense and tough material, perfect for construction.

Gabbro forms from molten magma rich in magnesium and iron. This magma gets trapped deep beneath the Earth’s surface. It cools down over thousands or even millions of years. Because the cooling is so slow, minerals have a lot of time to grow into large, interlocking crystals. This crystalline structure is what gives gabbro its high density and exceptional compressive strength. The primary components of this magma are plagioclase feldspar and pyroxene, which form the bulk of the rock.

What is the Composition and Properties of Gabbro?

Understanding gabbro’s properties shows you why it is such a valuable aggregate. Its primary minerals are plagioclase feldspar and pyroxene. It also often contains smaller amounts of olivine and amphibole.

Here are its key properties for construction:

- High Compressive Strength: Gabbro can withstand immense pressure without breaking. This makes it ideal for use in high-stress applications like building foundations and high-traffic roads.

- Excellent Durability: It is highly resistant to weathering, abrasion, and chemical attack. This means structures built with it last a very long time.

- High Density: Gabbro is a heavy rock. This provides stability when used as railway ballast or for erosion control projects.

- Low Water Absorption: Its non-porous nature means it does not absorb much water, making it resistant to freeze-thaw damage in cold climates.

What are Different Types of Gabbro Rock?

Not all gabbro is exactly the same. Geologists classify it based on the specific types and amounts of minerals it contains. For example, gabbro rich in the mineral olivine is called “olivine gabbro.” Another variety called “troctolite” has olivine and plagioclase but very little pyroxene. While these details are important for geologists, for crushing purposes, they are all considered hard, dense rocks that require a similar processing approach.

Where Can We Find the Gabbro Deposits?

Gabbro is a major component of the oceanic crust, the rock that underlies the world’s oceans. On land, it is found in large formations called “layered intrusions.” These are massive underground bodies of cooled magma. Some of the most famous gabbro deposits in the world are located in:

- The Bushveld Complex in South Africa

- The Stillwater Complex in Montana, USA

- The Skaergaard intrusion in Greenland

- Large deposits in parts of Canada and Australia

These large, concentrated deposits are ideal sites for quarrying operations.

What are Key Features of Gabbro Rock When Crushing It?

Crushing gabbro rock is very different from processing softer rocks like limestone. Its hardness and abrasiveness directly impact your choice of equipment and your operating costs.

Here is how it compares to other hard rocks:

- Gabbro: It is extremely hard and abrasive due to its interlocking crystalline structure. It requires high-powered jaw and cone crushers. The rock’s toughness means wear parts, like jaw plates and mantles, will wear out faster than with other rocks. However, it shatters into excellent cubical shapes, which is ideal for high-quality aggregate.

- Granite: Granite is also very hard and abrasive. However, it can sometimes be more brittle than gabbro, making it slightly easier to break in the primary crushing stage.

- Basalt: Basalt is the fine-grained equivalent of gabbro. It is also very tough and abrasive, but because its crystals are smaller, the wear on crusher liners can sometimes be slightly less than with a coarse-grained gabbro of similar composition.

- Diorite: Diorite is compositionally similar to gabbro and granite. It presents very similar crushing challenges and requires the same robust equipment.

What are Applications of Crushed Gabbro?

The superior physical properties of crushed gabbro make it a premium product for demanding construction jobs.

- High-Strength Concrete: Its strength and durability make it the preferred aggregate for high-rise buildings, bridges, and dams.

- Asphalt Pavement: The angular shape of crushed gabbro interlocks well, creating a stable and long-lasting road surface that resists rutting.

- Railway Ballast: Gabbro’s high density and resistance to abrasion provide a stable bed for railway tracks that can withstand the heavy loads and vibrations of trains.

- Riprap and Armor Stone: Large blocks of gabbro are used for building breakwaters and protecting shorelines from erosion because of their weight and durability.

Is It Profitable for Starting a Gabbro Crushing Project?

Yes, a gabbro crushing project can be very profitable, but it requires careful planning. The demand for high-quality gabbro aggregate is consistently strong, especially for infrastructure projects. Because of its premium quality, you can sell it at a higher price than lower-quality aggregates like limestone. However, the initial investment is higher. You need robust, heavy-duty crushers. Also, your operational costs will be higher due to increased energy consumption and more frequent replacement of wear parts. At ZONEDING, we focus on designing highly efficient crushing circuits that maximize output while minimizing these operational costs, which is the key to profitability.

What is the Whole Process of Crushing Gabbro Rock?

A typical gabbro crushing plant operates in multiple stages to efficiently reduce the rock size.

- Feeding: Large rocks from the quarry are loaded into a vibrating feeder. This machine controls the flow of material into the primary crusher.

- Primary Crushing: A heavy-duty jaw crusher for hard rock performs the first stage of size reduction. It crushes the large boulders down to a more manageable size, typically around 150-300mm.

- Secondary Crushing: The material from the jaw crusher is transported by conveyor belt to a cone crusher for gabbro. This machine crushes the rock further, down to about 20-60mm.

- Tertiary Crushing (Optional): If you need to produce fine aggregate or manufactured sand, the material goes to a third-stage crusher, often a Vertical Shaft Impactor (VSI) or another cone crusher.

- Screening: After each crushing stage, the material passes over vibrating screens. These screens separate the rock by size. Correctly sized products are sent to stockpiles, while oversized material is sent back to the appropriate crusher for further reduction.

What are Key Equipment of a Gabbro Rock Crusher Plant?

Choosing the right equipment is essential for success.

- Vibrating Feeder: To ensure a steady and controlled flow of material.

- Jaw Crusher: The workhorse for primary crushing of hard rock.

- Cone Crusher: The best choice for secondary and tertiary crushing of abrasive materials like gabbro. It produces a superior cubical shape.

- Vibrating Screen: To accurately classify the crushed aggregate into different sizes.

- Conveyor Belts: To transport material efficiently between machines.

- Vertical Shaft Impactor (VSI): Used in the final stage to shape the aggregate (improve cubicity) and produce manufactured sand.

What are Challenges in A Gabbro Crushing Plant and How to Solve Them?

Operating a gabbro crushing plant has specific challenges.

- High Wear on Parts: The extreme abrasiveness of gabbro causes jaw plates, cone liners, and blow bars to wear down quickly.

- Solution: Use high-quality wear parts made from manganese steel with a high chromium content. At ZONEDING, we offer premium wear parts designed for maximum lifespan in abrasive conditions. Schedule regular inspections and plan for part replacements to minimize downtime.

- High Energy Consumption: Crushing such a hard rock requires a lot of power.

- Solution: Design an efficient circuit that avoids re-crushing properly sized material. Use modern, energy-efficient motors and optimize the crusher settings to ensure you are not wasting power.

- Producing Dust: Crushing creates dust, which is an environmental and safety concern.

- Solution: An effective dust suppression system is essential. This can include water spray bars at key transfer points and covered conveyors. In some cases, a dust collection system (baghouse) may be required.

What is the Cost of Building a Gabbro Crushing Plant?

The cost of a gabbro crushing plant can vary widely, from a few hundred thousand to several million dollars. The main factors that influence the price are:

- Capacity: How many tons per hour do you want to produce? A 50 TPH plant is much cheaper than a 500 TPH plant.

- Final Product Sizes: If you need to produce many different sizes or manufactured sand, you will need more crushers and screens, which increases the cost.

- Level of Automation: A fully automated plant with a central control system will have a higher initial cost but can reduce labor costs over time.

As a direct manufacturer, ZONEDING can provide a more competitive price because we eliminate dealer markups. We work with you to design a plant that fits your specific budget and production goals.

How to Choose the Right Equipment for your Gabbro Crushing Plant?

Making the right choice is critical for your long-term success.

- Analyze Your Rock: First, get a detailed analysis of your gabbro deposit. Knowing its exact hardness, abrasiveness, and compressive strength will help select the right crusher models.

- Define Your Products: Decide what sizes of aggregate you want to sell. This will determine how many crushing and screening stages you need.

- Choose Robust Crushers: For primary crushing, a heavy-duty jaw crusher is non-negotiable. For secondary and tertiary stages, a cone crusher is superior to an impact crusher for abrasive rock like gabbro because it handles wear much better.

- Plan for the Future: Consider a plant design that allows for future expansion. It is easier to add another crusher later if the initial layout is planned correctly. We at ZONEDING specialize in creating these flexible and scalable plant designs for our clients.

What are the Features of Crushing Equipment from ZONEDING?

At ZONEDING, we design our equipment specifically for tough applications like gabbro crushing.

- Heavy-Duty Construction: Our machines are built with thicker steel plates and reinforced frames to withstand the high stress of crushing hard rock.

- Premium Wear Parts: We use high-manganese steel (Mn18Cr2) for our jaw plates and cone liners, ensuring a longer service life and reducing your cost per ton.

- High-Efficiency Design: The crushing chambers of our jaw and cone crushers are optimized to maximize throughput and produce a well-shaped final product.

- Reliable Components: We use high-quality components from trusted brands for motors, bearings, and hydraulics to ensure reliable operation and minimize downtime.

How to Choose a Reliable Equipment Supplier From China?

Choosing a supplier is a big decision. Here is what to look for:

- Look for a Manufacturer, Not a Trading Company: A direct manufacturer like ZONEDING has better quality control, technical expertise, and more competitive pricing.

- Check Their Experience: Ask for case studies and references of similar projects they have completed. A supplier with experience in crushing hard rock will understand your needs better.

- Evaluate Their Technical Support: Do they have professional engineers who can help you design your plant? Do they offer after-sales service and spare parts support?

- Visit the Factory if Possible: Seeing their production facilities and meeting their team in person is the best way to verify their capabilities.

What are the Environmental Impacts When We Crush Gabbro Rock?

A modern crushing plant must be designed to minimize its environmental footprint.

- Dust Emissions: This is the primary concern. As mentioned, water spray systems and dust collectors are effective solutions.

- Noise Pollution: Crushers are loud. Planting trees around the site can help create a natural sound barrier. Enclosing the main crushing stations can also significantly reduce noise levels.

- Water Management: Process water used for dust suppression should be collected in settling ponds and recycled to conserve water and prevent runoff.

FAQ

- Why is Gabbro a Premium Aggregate for Construction?

- Gabbro is a premium aggregate because of its exceptional strength, durability, and resistance to abrasion. It meets the strictest specifications for major infrastructure projects like highways, airports, and high-rise buildings, where lower-quality materials would fail.

- What are the Final Products You Can Sell from Crushed Gabbro?

- You can produce a range of valuable products. Common sizes include railway ballast (e.g., 40-70mm), concrete aggregate (e.g., 5-10mm, 10-20mm), and asphalt aggregate. You can also produce manufactured sand (0-5mm) as a high-quality alternative to natural sand.

- What are the Key Wear Parts You’ll Need to Replace Often?

- In a gabbro crushing plant, the most frequently replaced parts will be the jaw plates in the jaw crusher and the mantle and bowl liner in the cone crusher. If a VSI is used, the rotor tips and other internal wear plates will also need regular replacement.

- Can You Use a Mobile Crushing Plant for Gabbro Deposits?

- Yes, you can. A mobile crushing plant is an excellent option for some gabbro projects, especially for contractors who move between different sites or for opening a new quarry. However, for large-scale, long-term operations, a stationary plant is typically more efficient and has a lower cost per ton.