Before you can build a profitable mineral processing plant, you need a blueprint. Mineral beneficiation tests provide that essential blueprint for your ore.

My company, ZONEDING, has designed and built complete mineral processing plants since 1990, and every single successful project starts with thorough testing. This beneficiation checklist is to guide you through the critical mineral processing testing stages.

Following these steps helps you avoid costly mistakes, maximize your recovery rates, and ensure your project is profitable from day one.

Table of Contents

What is Mineral Beneficiation Tests?

Mineral beneficiation tests are a series of scientific analyses based on your ore samples. Think of it like a doctor running diagnostic tests before prescribing medicine. We analyze your ore to understand its unique physical and chemical properties. The goal of these tests is to find the most efficient and cost-effective method to separate the valuable minerals, a process we call creating a “flowsheet.” Without this data, you are just guessing, and in the mining industry, guessing can lead to multi-million dollar failures.

This testing process is the foundation of any successful mineral processing feasibility study checklist. It moves your project from a raw resource in the ground to a clear, data-driven plan for extraction. The results determine everything: what type of crushers you need, the size of your grinding mills, the specific chemical reagents to use, and अंततः, how much profit you can make.

Why Should We Test the Minerals for Beneficiation?

You should test your minerals because failing to do so is the biggest financial risk you can take in a mining project. Building a processing plant is incredibly expensive, and if you build the wrong kind of plant for your specific ore, it may never be profitable. Testing is not a cost; it is an investment that protects your entire capital expenditure. It provides the critical data needed to make informed decisions, secure financing from investors, and design a plant that actually works. Without proper testing, you are operating completely blind.

Here are the key financial reasons why mineral processing testing is non-negotiable:

- Maximize Recovery Rates: Testing can reveal if a small change in process can increase your recovery from 85% to 92%. For a gold mine, that 7% difference could mean millions of dollars in extra revenue each year.

- Optimize Operational Costs: Should you use a large-diameter SAG mill or a smaller ball mill? The right choice, determined by comminution testing, can save you hundreds of thousands of dollars in energy costs annually.

- Secure Investment: No serious investor or bank will finance a mining project without a bankable feasibility study from comprehensive metallurgical test work.

- Reduce Technical Risk: Testing identifies potential problems, like penalty elements or difficult-to-treat minerals, before you build the plant, allowing you to design solutions in advance.

When Should We do the Minerals Test?

You should start mineral testing as early as possible in the project lifecycle and continue it at key stages. It is not a one-time event. The complexity and scale of the tests will increase as the project advances and becomes more defined.

- Early Exploration Stage: Basic mineralogical analysis is to simply identify the valuable minerals and get a rough idea of liberation size. This helps determine if the project is even worth pursuing further.

- Scoping Study / Preliminary Economic Assessment (PEA): At this stage, you conduct initial bench-scale tests on a few representative samples. The goal is to develop a preliminary flowsheet and estimate initial recovery rates to see if the project has economic potential.

- Pre-Feasibility and Feasibility Study: This is the most intensive phase of testing. You will conduct detailed bench-scale tests and larger pilot-plant trials on many samples from across the ore body. The goal is to finalize the process flowsheet, confirm recovery rates, specify the major equipment, and produce data for detailed engineering.

- During Operation: Even after the plant is running, you may continue to test ore from new sections of the mine to optimize the plant’s performance.

What are Main Materials Can Be Tested?

Virtually any material that is mined from the earth can and should be tested to determine the best way to process it. The tests is to extract the specific minerals you hope to recover.

- Metallic Ores: These are the most common materials. This includes metallurgical test work for gold ore, copper, iron, lead, zinc, nickel, and lithium ores.

- Industrial Minerals: This category includes materials like quartz, feldspar, kaolin, phosphate, and potash. The goal here is often to achieve a certain level of purity rather than just extracting a metal.

- Construction Materials: Even materials like sand and gravel are sometimes to remove impurities or to produce specific size fractions for high-value applications.

- Mine Tailings: With modern technology, we can often re-process old tailings piles to recover valuable minerals that were missed by less efficient, older methods.

What are Different Methods to Test the Minerals?

There are several primary methods for separating minerals. The goal of the test work is to see which method, or combination of methods, works best for your ore.

Gravity Method

This method separates minerals based on their differences in specific gravity (density). It is one of the oldest, cheapest, and most environmentally friendly methods.

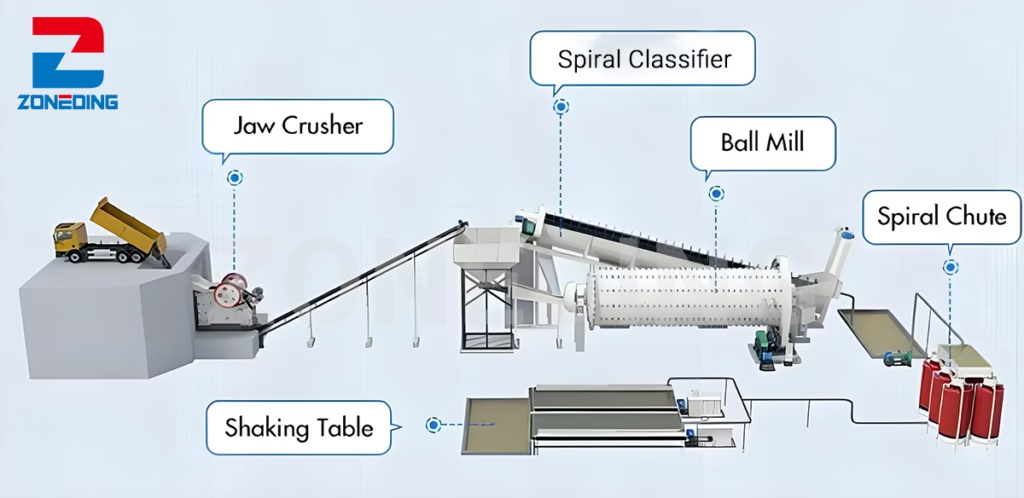

- Process: The test involves crushing and grinding the ore to a specific size, then passing it through equipment like a shaking table, spiral concentrator, or jig. The heavier, valuable minerals are separated from the lighter waste rock by gravity and water flow. It is very effective for minerals like gold, tin, and iron ore.

Flotation Method

Flotation is a more complex chemical process to separate fine mineral particles. It is the most common method for copper, lead, and zinc sulfide ores.

- Process: For flotation test work, the finely ground ore is mixed with water to form a slurry. We then add specific chemical reagents that make the valuable mineral particles water-repellent (hydrophobic). Air bubbles are passed through the slurry, and the hydrophobic mineral particles attach to the bubbles and float to the surface, where they are collected as a mineral-rich froth.

Magnetic Method

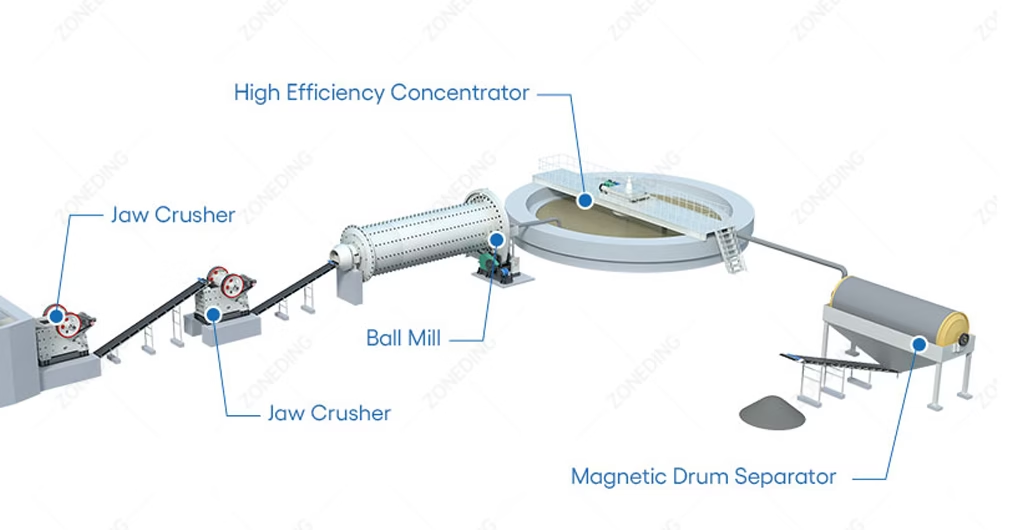

This method uses powerful magnets to separate minerals based on their magnetic properties. It is the primary method for concentrating iron ore (magnetite).

- Process: The ore is passed over magnetic drums or belts. Magnetic minerals are attracted to the magnet and are separated from the non-magnetic waste rock. The tests determine the required magnetic field strength and the best equipment configuration (wet or dry) for effective separation.

Joint Method

In reality, very few ores can be treated with a single method. A joint method, or combined flowsheet, is most common.

- Process: This involves using two or more of the methods above in sequence. For example, you might use gravity separation to recover coarse gold, and then use a flotation process on the leftover material to recover the very fine gold. Developing this combined flowsheet is a key outcome of a thorough test program.

What is the Basic Steps for Minerals Test?

A mineral testing program follows a logical progression, moving from broad analysis to specific process details.

- Ore Sampling and Preparation: The first step is to collect representative samples from your mine site. These samples are then crushed, split, and prepared in the laboratory for analysis.

- Chemical and Mineralogical Analysis: We first determine what minerals are present and how much of each. This is the importance of mineralogical analysis in beneficiation. It tells us the theoretical maximum amount of valuable material we can possibly recover.

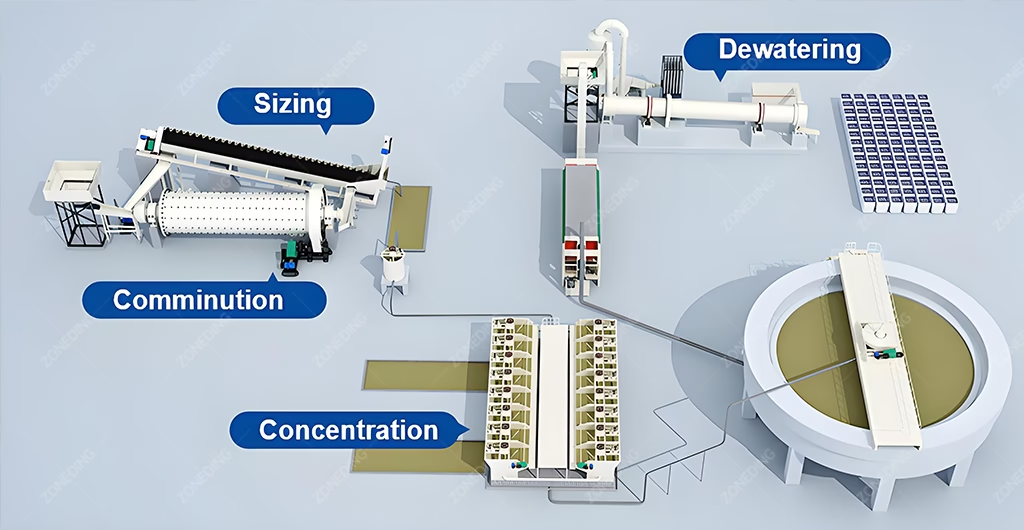

- Comminution Testing (Crushing and Grinding): We test how difficult your ore is to crush and grind. The Bond Work Index test procedure is a key part of this. The results determine the size and power of the crushers and grinding mills you will need, which are the biggest energy consumers in the plant.

- Bench-Scale Beneficiation Tests: This is where we test the different separation methods (gravity, flotation, magnetic) on small samples to find the best process. We experiment with different grind sizes, reagent types, and other variables to optimize recovery.

- Flowsheet Development: Based on the results of the bench-scale tests, our engineers develop a mineral processing flowsheet. This is the step-by-step “recipe” for your processing plant, showing the sequence of equipment and processes.

- Pilot Plant Testing (Optional but Recommended): For large projects, the flowsheet is at a larger scale in a pilot plant. This confirms the results from the bench tests and helps identify any potential problems before building the full-scale plant.

FAQ

- What is the cost of mineral beneficiation tests?

- The cost can range from a few thousand dollars for a basic analysis to over a million dollars for a full feasibility study with pilot plant trials. The cost depends entirely on the complexity of your ore and the level of detail required.

- How long does mineral testing take?

- A simple preliminary test program might take a few weeks. A full, bankable feasibility study test program can take 6 to 12 months or even longer, depending on the number of samples and the complexity of the flowsheet.

- Can I do the testing myself?

- Unless you have a fully equipped metallurgical laboratory and experienced metallurgists on staff, it is highly recommended to use a professional ore testing laboratory. The accuracy of the results is critical to the success of your entire project.

Conclusion and Final Advice

Completing a full program of mineral beneficiation tests is the most important step you will take toward building a successful and profitable mine. This beneficiation checklist provides a road map, guiding you from raw ore samples to a fully engineered, optimized process flowsheet. The data you gain will de-risk your project, attract investors, and ensure you build the right plant for your specific ore. Skipping or rushing this stage is a recipe for financial disaster.

Your final takeaway should be to approach testing methodically.

- Start with a thorough mineralogical analysis.

- Use the results to guide your comminution and beneficiation tests.

- Combine the best results to develop a complete and robust flowsheet.

Partnering with an experienced team is key to this process.