全站搜索

Search the entire website

Search the entire website

Building a new aggregate plant is one of the biggest investments you can make in the construction materials industry. It’s a complex undertaking with the potential for huge returns, but also significant risks. A successful plant isn’t just about buying powerful crushers and long conveyors; it’s a strategic fusion of geology, engineering, logistics, and market forecasting. Get the planning phase right, and you build a profitable operation for decades. Get it wrong, and you’re left with an inefficient, costly, and potentially useless pile of steel.

So, where do you begin? The temptation is to start by looking at equipment catalogues. That’s a mistake. The most successful operations start with a plan, not a purchase order.

As a company that has designed and equipped complete aggregate production lines on multiple continents, we’ve guided countless clients through this journey. We know that the real work happens long before the first piece of concrete is poured.

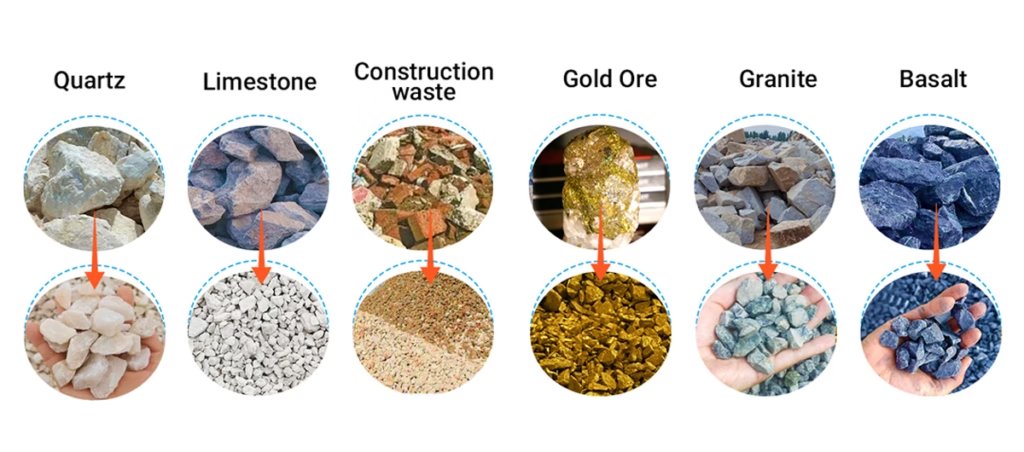

An aggregate plant, also known as a crushing and screening plant, is an industrial facility used to crush large rocks into smaller, specific sizes. It’s essentially a factory that manufactures the fundamental building blocks of modern construction: sand, gravel, and crushed stone.

The entire system is a multi-stage process designed to transform raw, extracted rock into valuable, graded products. A typical aggregate production line includes:

From start to finish, it’s a carefully engineered system designed for high output and consistent quality.

Yes, building an aggregate plant can be extremely profitable, but that profitability is not guaranteed. While the raw material (rock) is relatively inexpensive, the value—and therefore the profit—is created during the processing. The market for aggregates is stable and consistently growing with global infrastructure and housing needs.

However, profitability hinges entirely on careful planning and execution. The factors that determine whether an aggregate plant will be a financial success include:

In short, profitability is a direct result of the strategic decisions you make long before you crush the first rock. The following 7 factors are the roadmap to ensuring your investment pays off.

Before you even think about rock, you must think about customers. An aggregate plant is only profitable if you can consistently sell what it produces. You must begin with a thorough market analysis.

You need to identify your target market. Are you aiming for large infrastructure projects that need huge volumes of road base? Or are you targeting the ready-mix concrete market, which requires high-quality, cubical aggregate? Each market has different product specifications, pricing, and volume demands.

You must also analyze your competition. Who are the existing suppliers in the area? What are their strengths and weaknesses? Can you compete on price, quality, location, or service? Don’t enter a saturated market without a clear competitive advantage. A detailed market study is the foundation of your business plan and will guide every subsequent decision.

This is the most critical technical step. Amateurs buy machines; professionals design a plant around the geology. You must know exactly what is in the ground before you can decide how to process it.

You must conduct extensive testing. This involves core drilling across your entire proposed site to understand the deposit’s quality, consistency, and depth. You need to test for key properties that will directly impact your aggregate plant design:

At ZONEDING, our process always starts here. We analyze our client’s geological reports to recommend a crushing and screening plant that is perfectly matched to the raw material. Fitting the plant to the rock is the secret to efficiency and profitability.

Finding a site with good rock is only the beginning. Building the plant is often the easy part; getting permission to build it is the real project.

Permitting can take years. This phase is the single biggest source of delays and budget overruns. The process is far more than a simple zoning application. You will likely need to conduct:

Community relations are crucial. You must engage with local communities early and address their concerns transparently. One organized opposition group can tie your project up in legal battles for years. Underestimating the time, cost, and complexity of permitting can kill your project before it even starts.

An aggregate plant is a logistics operation that happens to crush rock. Your biggest bottlenecks and operational costs will come from moving material inefficiently. And your quarry plant setup must prioritize a smooth, logical flow.

Your layout should minimize material handling. Every time you move the rock with a loader or a truck, it costs you money. A well-designed layout uses gravity and conveyors effectively to move material between processing stages. Haul roads from the quarry face to the primary crusher must be wide, well-maintained, and have gentle grades.

You need to plan for the “hidden factory.” This includes your stockpile areas. Are they large enough? Are they designed to prevent contamination between different product sizes? Is there enough room for loaders and customer trucks to operate safely and efficiently without creating a bottleneck? A poorly designed yard can cripple the output of a multi-million dollar crushing circuit.

As part of our complete plant design service, ZONEDING uses advanced software to model material flow. We design layouts that optimize truck cycles, minimize conveyor lengths, and ensure your entire operation runs like a well-oiled machine.

Now, based on the first four factors, you can finally start selecting equipment. Your choice should be a direct result of your market analysis and geological evaluation.

| If Your Rock Is… | You Will Likely Need… | Why? |

|---|---|---|

| Hard & Abrasive (e.g., Granite) | A Primary Jaw Crusher + Secondary Cone Crusher | Jaws are excellent for breaking large, hard rock. Cones are efficient at secondary crushing and shaping abrasive materials. |

| Softer & Non-Abrasive (e.g., Limestone) | A Primary Jaw Crusher + Secondary Impact Crusher | Impact crushers are very efficient with softer rock and produce an excellent cubical product, but their wear parts are expensive with abrasive material. |

| Full of Clay and Fines | A Vibrating Screen before the primary crusher (a “scalper”) and a full wash plant with a sand washer. | To remove the useless fines and clay early, so you don’t waste energy crushing them. A wash plant is needed to produce clean, high-value aggregate. |

It’s about choosing a balanced system where each machine’s capacity matches the next. An undersized screen can choke a high-capacity crusher, wasting its potential. ZONEDING’s comprehensive product line allows us to supply a fully integrated and balanced plant, from the primary feeder to the final stockpile conveyors.

Water is essential for dust control and washing aggregate, but it is a major operational challenge and cost.

You need a sustainable water source. Can you access river water, or will you need to drill wells? This is a key site selection factor.

You must plan for water recycling. Environmental regulations are getting stricter everywhere. You can no longer just discharge dirty water into a stream. A modern aggregate plant must include a sophisticated water management system. This typically involves:

This system is a significant part of the aggregate plant cost. Designing it correctly from the start will save you money and keep you in compliance with environmental laws.

The best plant in the world is useless without a skilled team and solid processes to run it. Before you start crushing, you need a plan for your operations.

Thinking about these operational details during the design phase allows you to incorporate features like maintenance-friendly layouts, centralized control rooms, and on-site QC labs.

Building a new aggregate plant is a monumental task, but you don’t have to do it alone. The key is to work with a partner who understands the entire process, not just how to sell you a machine.

At ZONEDING, we provide true end-to-end solutions. Our team of experienced engineers works with you from the very beginning. We help you analyze your rock, design the most efficient plant layout, select the perfectly balanced equipment, and provide support through installation, commissioning, and training. And We are not just a supplier; we are your partner in building a profitable future.

If you are considering a new aggregate plant project, contact us today. Let’s start the conversation and build your success story together.

About manufactured sand (M-Sand): its definition, production process, applications in construction, and advantages over natural sand. Contact ZONEDING Now!

View detailsNew to mobile crushers? This guide clearly introduces their concept, key features, types, and widespread applications across various industries.

View detailsExplore the 10 most common minerals, from Quartz to Halite. Discover their fascinating and essential uses in technology, construction, and your daily life.

View detailsNew to construction materials? This guide breaks down 5 basic types of sand, from Pit Sand to M-Sand, explaining their properties in easy-to-understand terms.

View details