全站搜索

Search the entire website

Search the entire website

Are you looking for a steady, high-quality source of sand for your construction projects? With natural sand becoming scarce, Manufactured Sand (M-Sand) is the solution. This is a superior, engineered alternative to river sand, produced by crushing rocks. We’ll show you how it’s made and why it’s the future of construction.

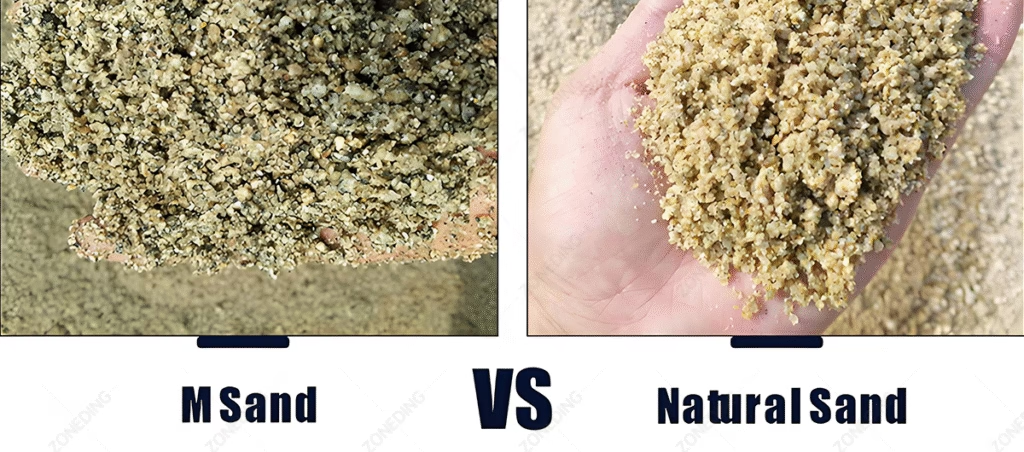

Manufactured Sand is not just crushed rock; it’s an engineered fine aggregate. We produce it by crushing specific hard stones, like granite or basalt, in a multi-stage process. Unlike natural sand, which is often rounded and inconsistently graded, M-Sand has a cubical shape and a controlled particle size distribution.

The goal isn’t simply to make small rocks. The real secret is to create particles with the perfect shape and size mix. This engineering ensures the sand has minimal voids when mixed in concrete. This leads to stronger, more durable structures. At ZONEDING, we specialize in the technology that creates this perfect, cubical sand.

We need M-Sand because the world is running out of natural river sand. Aggressive river sand mining causes severe environmental damage, including riverbed erosion and harm to aquatic life. Many governments have restricted or banned it. This has created a massive sand shortage and price volatility.

For your business, this presents a huge opportunity. M-Sand provides a reliable, eco-friendly, and often higher-quality alternative. By setting up a sand production line, you can produce a consistent supply of construction-grade sand, independent of unreliable natural sources. It’s a sustainable business model for a world that needs to build.

M-Sand is a versatile material used in all major construction applications. Because of its superior quality and consistency, it often performs better than natural sand. You can use it for:

The primary advantage of M-Sand is its consistent quality and engineered properties. However, the initial investment is a key consideration.

| Advantages of M-Sand | Disadvantages of M-Sand |

|---|---|

| Consistent Quality: Free from clay, silt, and impurities. | High Initial Cost: Requires investment in a full production line. |

| Optimal Shape: Cubical shape provides better strength and workability. | Requires Expertise: Proper equipment and process control are crucial. |

| Eco-Friendly: Reduces damage to river ecosystems. | Energy Consumption: The crushing process requires significant power. |

| Reliable Supply: Can be produced on-demand near construction sites. | Potential for Flakiness: Poor quality crushers can produce flaky particles. |

| Higher Concrete Strength: Fewer voids lead to denser, stronger concrete. | Dust Generation: A dry process plant requires dust control systems. |

The main difference lies in shape, purity, and consistency. Natural sand is shaped by nature, while manufactured sand is shaped by technology.

| Feature | Natural Sand (River Sand) | Manufactured Sand (M-Sand) |

|---|---|---|

| Shape | Rounded or irregular, worn by water. | Cubical and angular, from crushing. |

| Grading | Inconsistent, varies by location. | Controlled and consistent, as per standards. |

| Purity | Often contains silt, clay, organic impurities. | Free from impurities, washed or air-screened. |

| Availability | Becoming scarce, geographically limited. | Can be produced anywhere with suitable rock. |

| Moisture | High and variable moisture content. | Low moisture content, especially in dry process. |

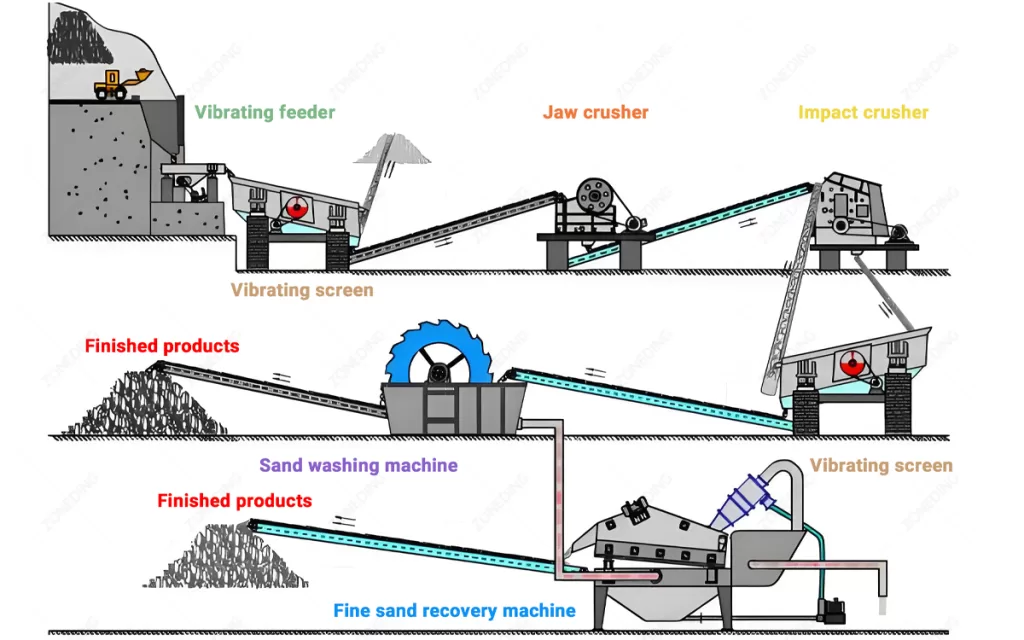

Producing M-Sand is a systematic process involving multiple stages of crushing and screening. It’s not about using just one machine; it’s about designing a complete circuit.

Your choice depends on water availability, environmental regulations, and your target product. Both methods have their place, and at ZONEDING, we design both types of plants.

A successful M-sand plant is a complete system, not just one machine. You are buying a process, and every piece of equipment plays a vital role. A typical ZONEDING plant includes:

You can use almost any hard rock, but the quality of the raw material affects the final sand. The best raw materials have high hardness and low impurity levels. We can help you test your rock to determine its suitability. Common sources include:

Control comes from using the right technology, primarily the VSI Sand Maker and the Vibrating Screen.

The key is precise temperature and time control in the rotary kiln.

The VSI Crusher is the key to particle shape. It uses a principle called “rock-on-rock” crushing. Inside the machine, a high-speed rotor flings rocks outwards, causing them to collide with other rocks in the crushing chamber. These high-impact collisions break the stone along its natural fissure lines, resulting in a superior cubical shape rather than the flaky shape produced by simple compression crushers.

The Vibrating Screen is what controls the grading. By using screen meshes with different aperture sizes, you can precisely separate the sand into the required fractions (e.g., 0-5mm) and remove any oversized particles for re-crushing.

Your M-Sand must meet specific national or international standards to be accepted for construction. These standards define the acceptable limits for particle size distribution (gradation), shape, and cleanliness.

Common standards include ASTM C33 (in the USA) or IS 383 (in India). They typically specify:

The total cost is more than just the price of the machines. When you request a quote, you should consider the complete project investment.

Capital Expenditure (CAPEX):

Operational Expenditure (OPEX):

We provide complete, customized solutions, not just individual machines. With over 30 years of experience, we understand that every quarry is different. Our process starts with analyzing your raw material and your market needs.

We then design a sand production line that is optimized for efficiency and produces high-quality M-Sand that meets all standards. Our high-performance VSI Sand Makers are engineered for low wear costs and produce superior cubical particles. From initial design and manufacturing to installation and training, ZONEDING is your partner in building a profitable and sustainable sand business.

Understand ore processing (mineral processing). We define how raw mined ore is separated into minerals and waste rock through crushing and separation.

View detailsDelve into dolomite:definition, properties,formation, and industrial processes for mining, crushing, grinding, and calcining it for various applications.

View detailsThink you know cone crusher liners? Our blog reveals surprising facts about selection, wear, and replacement that could save you time and money.

View detailsExplore detailed insights into limonite's extraction, beneficiation, and treatment methods.Learn its roles as an iron ore & pigment source in modern industries.

View details