If your crushed stone or gravel is full of clay, silt, and other debris, it is a big problem for your construction projects. Dirty aggregate leads to weak concrete and poor asphalt bonding, which can cause structures to fail. The solution is coarse material washing. This guide will explain why washing is so important. I will walk you through the different types of machines and help you choose the right one. This will help you produce high-quality, valuable aggregate for any project.

Table of Contents

What is Coarse Material?

Coarse material is simply large-sized aggregate. When we talk about coarse materials, we mean gravel, crushed stone, and other rock fragments. These are generally larger than 4.75mm, or about 3/16 of an inch. Think of the stones you see in ready-mix concrete or the gravel used for road bases. This material is the backbone of many construction projects. Its quality is extremely important for strength and stability.

We separate it from “fine material,” which is sand. The size and cleanliness of your coarse material directly impact the strength and durability of your final product. This is why you cannot afford to have it contaminated with unwanted substances like clay or silt. The entire purpose of an aggregate washing plant is to make sure your coarse material is perfectly clean before you use it.

Why is it Important for Coarse Material Washing?

Washing coarse material removes harmful contaminants that weaken your final product. Things like clay, silt, dust, and organic matter act as a barrier. They prevent the aggregate from bonding strongly with cement or asphalt. Using dirty aggregate is like trying to glue two dusty surfaces together. The glue sticks to the dust, not the surface itself. This creates a very weak connection.

The results of using unwashed material are serious and costly. You get weaker concrete that can crack under pressure or fail over time. You get asphalt that unravels easily, creating potholes and unsafe roads. For any project that requires strength and longevity, coarse material washing is not just an option; it is a necessary step. It is how you guarantee quality and safety. Clean aggregate is a core part of all modern, reliable construction.

What are Applications for Coarse Material Washing?

Clean coarse material is needed in almost every type of construction. Any time you need to create a strong, reliable final product, the quality of your aggregate is the first thing to consider. Washing is a key step in producing these high-grade materials. The demand for clean aggregate is constantly growing as building standards become stricter.

Some of the most common applications include:

- Concrete Production: For ready-mix concrete, precast blocks, pipes, and other concrete products.

- Asphalt Production: Creating clean aggregate for strong and durable road paving.

- Construction Fill: Producing clean drainage stone and stable base materials for foundations and roads.

- Specialty Sands: Washing aggregates before crushing them into high-quality manufactured sand.

- Environmental Remediation: Cleaning contaminated soils and gravel as part of site cleanup projects.

- Railway Ballast: Providing clean, durable stone to support railway tracks.

What Materials Can Be Removed by Washing Coarse Material?

A good aggregate washing plant can remove a wide range of unwanted materials. The main job of the washer is to break down and wash away the sticky, fine particles that cling to the surface of your valuable stone. Even a small amount of these contaminants can have a big negative effect on your final product’s quality.

The most common materials we design our machines to remove are:

- Clay and Silt: These are the biggest problems. They absorb water and create weak points in concrete.

- Fine Dust and Rock Fines: This is leftover material from the crushing process that can weaken bonds.

- Lightweight Debris: Things like wood chips, roots, leaves, and other organic matter can rot and create voids.

- Soluble Salts: Certain salts can cause chemical reactions that damage and degrade concrete over time.

- Coatings: Some rock has soft coatings or weathered surfaces that need to be scrubbed off.

What are Coarse Material Washer Types?

There are several types of machines, each designed for different levels of contamination. The three most common types are Screw Washers, Log Washers, and Blade Washers. Choosing the right one depends entirely on how dirty your material is and what kind of contamination you are dealing with.

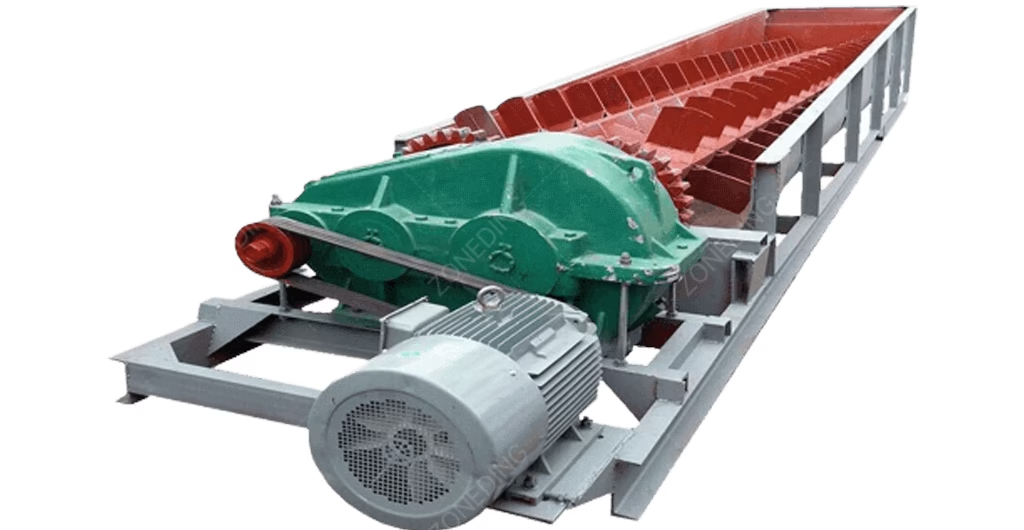

Screw Washers

A Coarse Material Screw Washer uses a large, rotating screw inside an inclined tub. You feed dirty material into the lower end of the tub with water. As the screw turns, it tumbles the material against itself, which scrubs the surfaces clean. The dirty water and fine contaminants overflow from a weir at the back. Meanwhile, the clean aggregate is carried up the screw and discharged at the top, dewatered and ready to use.

- Advantages: Excellent for removing light clays, silts, and dust. It also dewaters the material very effectively as it travels up the incline. They are generally more affordable and consume less power than Log Washers.

- Work Principle: It works on a simple principle of scrubbing and classification. The gentle tumbling action is enough to loosen light contaminants. These are then separated and carried away by the upward flow of water.

- Applicable Materials: It is the best choice for crushed stone or gravel with light to moderate amounts of non-sticky clay, silt, and crusher dust.

Log Washers

A Log Washer is a heavy-duty scrubbing machine built for the toughest jobs. It features two massive shafts, or “logs,” with very durable paddles. These shafts rotate in opposite directions inside a tub. This creates an intense, grinding action that breaks down even the toughest, stickiest clays. The severe scrubbing action is what separates a log washer from a screw washer. It is designed for maximum force and attrition.

- Advantages: It is unmatched for removing heavy, plastic clays and cemented aggregates. The intense paddle action can break apart large clumps of dirt that a screw washer could never handle. They are built for extreme-duty applications and a long service life.

- Work Principle: It relies on intense material-on-material attrition. The paddles continuously lift and drop the rock, forcing it to grind against itself. This powerful shearing action is what rips the clay off the stone surfaces.

- Applicable Materials: It is essential for river gravel with heavy clay, hard-to-wash crushed rock, and any feed material with a high percentage of tough, plastic clay.

Blade Washers (Blade Mills)

A Blade Washer, sometimes called a Blade Mill, is another type of aggressive scrubbing machine. It looks similar to a log washer but often uses a different paddle design. The paddles, or blades, are designed to create both a scrubbing and a cutting action. This is particularly useful when the feed material contains not just clay but also other debris like roots or soft, friable materials that need to be broken up.

- Advantages: It is very effective at breaking up clay balls while also chopping up organic debris. It provides a vigorous washing action that is more intense than a screw washer but may be slightly less forceful on hard, cemented clays than a log washer.

- Work Principle: The blades rotate on one or two shafts, creating a turbulent slurry. This action scrubs the rock surfaces and simultaneously cuts and shreds lighter contaminants, allowing them to be washed away with the overflow water.

- Applicable Materials: It is a great choice for aggregate deposits with a mix of sticky clay and organic materials like roots and sticks. It is also good for some industrial applications like washing contaminated soils.

What Feed Size and Capacity Can These Washers Handle?

These washers are designed for a range of sizes and production rates. It is critical to match the machine’s specifications to your material and your operational needs. Feeding oversized rock into a washer can cause serious damage, while choosing a machine that is too small for your capacity will create a bottleneck in your plant.

- Feed Size: Coarse Material Screw Washers can typically handle material up to 75mm (3 inches). Log Washers and Blade Washers are more robust and can often accept feed sizes up to 100mm (4 inches) or even larger, depending on the model. You should always check the manufacturer’s recommended maximum feed size.

- Capacity: The capacity of these machines is measured in tons per hour (TPH). Smaller screw washers might process around 50 TPH, while large, heavy-duty log washers can handle 300 TPH or more. Your required capacity will be a major factor in determining the size and cost of the machine you need.

How to Choose the Right Coarse Material Washers for Your Project?

You must match the machine to the type and amount of contamination. A common and expensive mistake is buying a screw washer for a job that really needs a log washer. This leads to a poor-quality final product and wasted money. Making the right choice from the start is the most important step.

Here is a simple way to decide:

- Analyze Your Feed Material: This is the most critical step. Take a sample of your aggregate and mix it with water in a clear jar. Shake it vigorously and let it settle. If the clay easily dissolves and makes the water cloudy, a Screw Washer is likely sufficient. If the clay forms sticky, stubborn clumps at the bottom that do not break apart, you absolutely need a Log Washer or Blade Washer.

- Consider Your Capacity Needs: How many tons per hour do you need to process to meet your sales goals? Be sure to choose a machine that can comfortably handle your target production rate.

- Evaluate Your Feed Size: Screen your material before it enters the washer to remove any oversized rocks. This will protect your machine from damage and ensure it operates efficiently.

- Think About Your Water Resources: All washing requires a significant amount of water. You need to plan for how you will supply this water and how you will manage the resulting wastewater and sludge.

What are the Key Factors that Determine the Coarse Material Washers Price?

The price of a coarse material washer can range from $20,000 to over $150,000. The cost is influenced by several key factors. Understanding them helps you see what you are paying for and why a cheaper machine may not be the best value in the long run.

- Type of Washer: Log Washers are more complex and heavily built than Screw Washers, so they have a higher initial cost. Blade Washers are typically priced similarly to Log Washers.

- Size and Capacity: A larger machine that processes more tons per hour will cost significantly more.

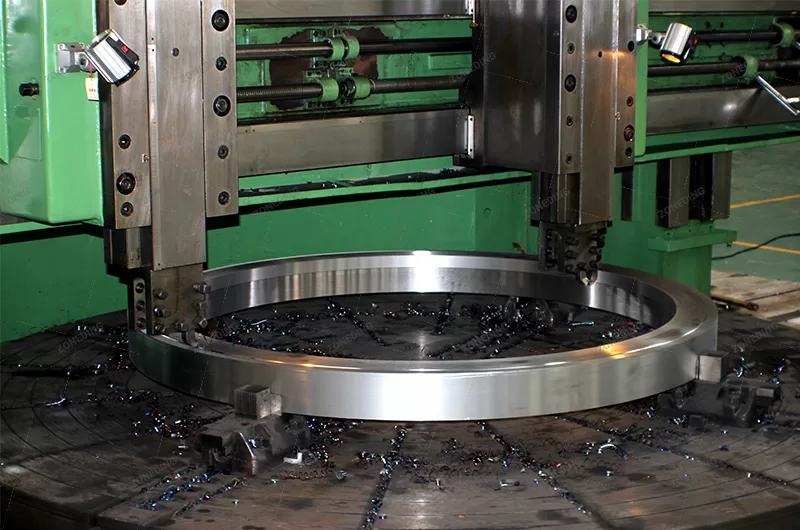

- Build Quality: This is a major factor. The thickness of the steel, the quality of the gearbox and bearings, and the type of wear materials (like polyurethane shoes or high-chrome iron paddles) all impact the price and the machine’s lifespan.

- Motor and Drive System: A more powerful motor and a heavy-duty drive system add to the cost but are essential for reliability.

What is the Typical Maintenance for a Coarse Material Washer?

Good maintenance is key to keeping your washer running for years. These machines work in a tough, wet, and abrasive environment. Neglecting maintenance will lead to costly breakdowns. Daily and weekly checks are essential for a reliable operation.

Here is a basic maintenance schedule you can follow:

- Daily: Check lubrication levels in the gearbox and bearings. Listen for any unusual noises or vibrations during operation. Ensure all safety guards are securely in place.

- Weekly: Inspect the screw flights or log washer paddles for wear. If they are worn, they will not clean effectively. Tension the drive belts to prevent slippage. Grease all lubrication fittings.

- Monthly: Check all bolts for tightness, especially the ones holding the wear components like paddles or shoes. Inspect the inside of the tub for any signs of wear or damage.

What are Features of Coarse Material Washers from ZONEDING?

At ZONEDING, we build our washing equipment to be tough and reliable. We know that downtime costs you money, so our primary focus is on durability and performance. We have over 30 years of experience providing complete production lines, from crushing and washing to screening and Minerals Processing Plant. We understand the entire process.

Our washers are designed with features that matter to you:

- Heavy-Duty Construction: We use thick, high-quality steel for the tubs and robust structural supports to handle heavy loads and constant vibration without failing.

- High-Quality Wear Parts: Our screw flights and log washer paddles are made from highly abrasion-resistant materials. This means they last longer, saving you money on replacement parts and labor.

- Efficient Drive Systems: We use reliable, oversized gearboxes and energy-efficient motors to provide consistent power without wasting electricity.

- Customization: We work with you to configure the right washer for your specific material and production goals. We ensure you get the best cleaning performance for your investment.

FAQ

- How Much Water is Required for an Effective Washing Plant?

- A good rule of thumb is you need about 2 to 4 cubic meters of water for every ton of aggregate you wash. The exact amount depends on how dirty the material is. A system with settling ponds or a water clarifier can help you recycle a large portion of this water, reducing your environmental impact and operational costs.

- What are some operational tips for Coarse Material Screw Washers?

- First, always maintain the correct water level in the tub. Too little water will not clean effectively. Too much water will cause you to lose valuable fine material out the back. Second, control the feed rate. Overloading the screw will reduce cleaning efficiency and can strain the drive system, leading to premature wear.

- Can a Log Washer remove roots and sticks?

- Yes, to an extent. The intense scrubbing action helps break down organic matter. Lighter materials like wood chips and roots will float to the surface. They can then be discharged with the wastewater overflow. This helps to further clean your final aggregate product.