全站搜索

Search the entire website

Search the entire website

Choosing the right crushing plant design is one of the most important decisions you make for your aggregate or mining operation. This choice directly impacts your product quality, operational costs, and overall efficiency. As an industry expert, I understand the complexities involved. You might wonder whether an open-circuit crushing system or a closed-circuit crushing system fits your needs better. This guide will clarify the differences. It will help you understand the advantages and disadvantages of each. By the end, you will have a clear idea of which crushing system is best for your project.

An open-circuit crushing plant is the simpler of the two designs. In this setup, material passes through a crusher one time. Then, it discharges directly. Significantly, there are no screens in the main crushing path designed to return oversized material for re-crushing. This setup works like a straightforward production line. Material goes in one end. It comes out the other. ZONEDING recognizes that this simplicity often makes it beneficial for specific applications where high precision in product sizing is not the primary goal.

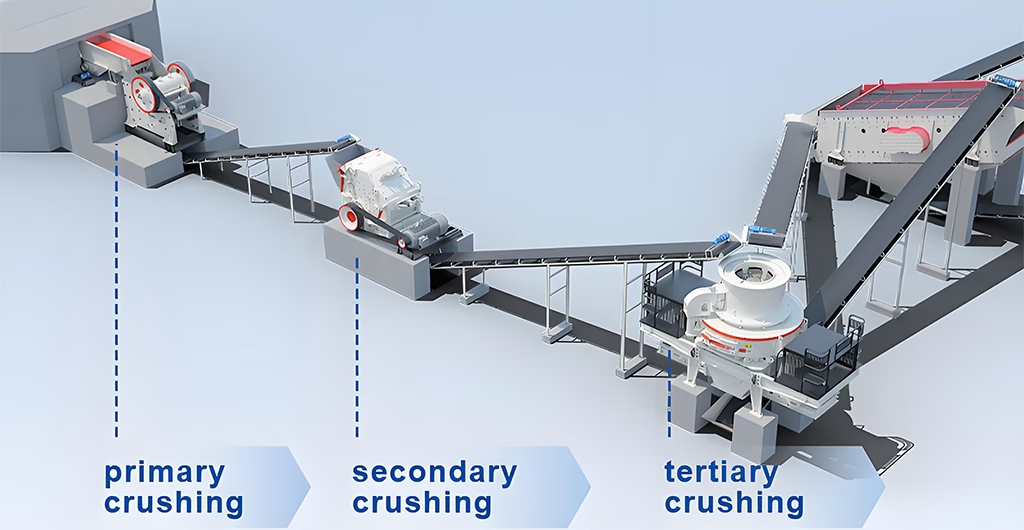

The work process for an open-circuit plant is quite direct. First, a feeder introduces raw material into the primary crusher. This powerful machine breaks down the large rocks into smaller pieces. After primary crushing, further material movement occurs. It might go to a secondary crusher for continued size reduction.

Alternatively, it might convey directly to a stockpile. The key point is that once material leaves a crusher, operators do not send it back for another pass. There are no screens to separate oversized particles and return them to the crusher. This creates a one-way flow for the material. The material passes through a crusher, undergoes size reduction, and then exits the system. This straight-line design makes the entire process easy to understand and manage.

Open-circuit crushing plants offer several benefits due to their straightforward nature.

First, they require lower initial investment. You need fewer machines and fewer conveyors. Subsequently, this results in less capital expenditure (CAPEX). Second, they boast reduced maintenance needs. There are fewer moving parts. As a result, this means fewer potential breakdown points and a simpler maintenance schedule. Third, these plants offer lower operational complexity. You need less oversight and fewer operators. The streamlined process is simpler to manage. Finally, they feature less power consumption per hour. Material passes through crushers only once. This reduces the total energy required during operation.

These plants suit projects with budget constraints. Also, they work well for operations where precise final product specifications are not extremely strict.

Despite their simplicity, open-circuit crushing plants have limitations. One significant drawback is less product control. The final product size and shape are less regulated. This in turn leads to inconsistent output. The output can indeed vary because it lacks recirculation of oversized material. Therefore, you might observe a lower quality aggregate. You might get a wider range of particle sizes.

Furthermore, you might get more flaky or elongated particles. This can lead to lower quality aggregate that does not meet stringent standards. Lastly, there can be higher waste. Oversized material that does not meet specifications often gets stockpiled or discarded. This reduces overall efficiency for certain applications. Indeed, these plants may struggle to meet strict aggregate quality control standards.

Open-circuit crushing plants fit well in specific scenarios. Therefore, they prove excellent for initial material reduction in large-scale aggregate production. When you need a general reduction in size before further processing, they excel in general size reduction.

ZONEDING also finds them effective in mines and quarries. For projects handling a wide range of material sizes where precision is not paramount, it is a good choice. For example, they work well for quarrying fill material or base course for roads. Moreover, they are perfect for primary crushing stages in mining operations. They prepare material for secondary crushing by a closed circuit. ZONEDING recommends these setups for simplicity and cost-effectiveness when strict material sizing is not critical.

A closed-circuit crushing plant is a more sophisticated and effective crushing system. It incorporates screens into the circuit. These screens separate material that is already small enough. Then, they return oversized material to the crusher for re-processing. This recirculation loop is what defines a closed circuit. The system continuously processes material until it meets the desired size specifications. This design offers a higher degree of control. ZONEDING often designs these plants for clients who demand precise product sizing and consistent quality, making it a cornerstone of modern stone crusher plant design.

A closed-circuit crushing plant operates with a recirculation loop. Raw material enters the primary crusher, where initial breakdown occurs. Afterward, it efficiently moves to secondary (and perhaps tertiary) crushers for further refinement. Importantly, after passing through a crusher, the material goes over a screen. This screen cleverly separates the material into two streams. First, the finished product, which is already at or below the target size, goes to a stockpile. Second, oversized material, still too large (the oversized fraction), is sent back via a conveyor to the entrance of the crusher it last passed through. This continuous loop ensures all material eventually meets the required size. This consistency guarantees a higher quality end product.

Closed-circuit crushing plants offer significant advantages for demanding projects. They provide superior product control. You get excellent command over final product size and shape. Consequently, this leads to consistent output. Continuous recirculation ensures all material eventually meets specifications. This results in a more consistent and higher-quality final product. Moreover, they allow for minimized waste. You minimize waste by reusing oversized material.

Furthermore, you maximize the yield of sellable product. This leads to better profitability for high-value aggregates. Finally, they achieve higher crusher efficiency. Crushers operate more efficiently when choke-fed with recirculated material. This often lowers overall crushing plant cost per ton of finished product. This setup achieves precise aggregate quality control. Therefore, it is an ideal crushing system for demanding markets.

Closed-circuit crushing plants come with their own set of challenges. First, they involve a higher initial capital investment (CAPEX). They are more complex in design. You need more equipment, including additional screens, conveyors, and sometimes surge bins. Secondly, they incur higher operational costs (OPEX). More machines mean higher power consumption and more maintenance points. Lastly, there is increased complexity. Troubleshooting can be more involved. Downtime can impact multiple interconnected machines, which requires experienced operators and maintenance crew. However, the benefits in product quality often outweigh these disadvantages for high-specification products. These complexities require meticulous stone crusher plant design.

Closed-circuit crushing plants are essential for demanding applications. For instance, they excel in precise aggregate sizing. They perform well where precise aggregate sizing and cubical product shape are critical. This includes producing aggregates for asphalt and concrete mixes. They are also vital in specialized mining applications. Consistent particle size is necessary for efficient mineral processing in these scenarios. Furthermore, ZONEDING finds them indispensable for high-quality sand production. Projects aiming for high-quality sand production also benefit greatly from closed circuits. ZONEDING frequently designs these comprehensive crushing systems for clients who require stringent aggregate quality control and maximum yield of highly specified products.

Understanding the core differences helps you pick the best system. These distinctions impact every facet of your operation.

In an open-circuit crushing plant, material moves in a straightforward, one-way direction. It passes through each crusher only once. There is no return path for oversized particles. Conversely, a closed-circuit crushing system incorporates a recirculation loop. Material flows through crushers and then over screens. Oversized material effectively returns to the crusher for further breakdown. This continuous loop ensures all material eventually meets the required size.

An open-circuit setup is inherently simpler to operate. It involves fewer components and a linear material flow. This simplicity often translates to easier management for your team. On the other hand, a closed-circuit plant is more complex. It involves interconnected machines, including multiple crushers, screens, and an array of conveyors. This intricate system requires more sophisticated control and oversight.

With an open-circuit crushing plant, you have less precise control over the final product size and shape. Since there is no recirculation, the output can be inconsistent. In contrast, a closed-circuit system offers excellent control. All material is crushed to the target size through continuous recirculation. This results in a highly consistent and uniform product, essential for specific quality demands.

Generally, an open-circuit crushing plant boasts a lower initial capital expenditure (CAPEX). It requires fewer crushers, screens, and conveyors due to its simpler design. Conversely, a closed-circuit system usually demands higher initial investment. It involves more equipment and often sophisticated control systems, increasing the upfront cost for your project.

An open-circuit plant might have potentially lower energy costs per hour. This occurs because material passes through crushers only once. However, it often leads to higher waste due to less product control. Therefore, the cost per ton of saleable product might be higher. A closed-circuit system, while consuming more energy per hour due to recirculation, maximizes the yield of sellable product. This minimizes waste and potentially leads to a lower overall cost per ton of usable material.

An open-circuit system is simple in its operation. However, it can be wasteful if product quality or precise sizing is important for your end product. A closed-circuit system, conversely, offers higher overall efficiency. This efficiency is measured both in terms of product yield and consistent quality. It effectively minimizes waste by ensuring all material is processed to spec.

Open-circuit crushing plants typically have lower maintenance needs. They feature fewer components, leading to a simpler maintenance schedule and reduced parts inventory. A closed-circuit system, by contrast, involves higher maintenance requirements. More crushers, screens, conveyors, and control systems mean more potential points for wear and tear, necessitating more frequent checks and repairs.

Open-circuit systems offer less flexibility. Changing product size primarily means adjusting crusher settings. This often results in a wide range of particle sizes or less consistent grading. A closed-circuit system is generally more flexible. You can adjust screen sizes and optimize crusher settings more precisely. This allows for the production of various product sizes and shapes, adapting to different market demands.

The defining characteristic of an open-circuit system is the absence of recirculation. All material moves forward in a continuous flow after passing through a crusher. Conversely, a closed-circuit system features continuous recirculation. It sends oversized material back to the appropriate crusher. This ensures repeated processing until the material meets the desired specifications.

Deciding on the right crushing system involves more than just understanding the differences. You must also consider your specific operational needs.

We at ZONEDING help clients evaluate these factors. Then, we design an optimal crushing setup that best meets their goals, ensuring efficiency and compliance.

Understanding the core machinery helps illustrate the setups. Each circuit utilizes a specific set of equipment to achieve its function.

Our ZONEDING equipment range covers all these necessities. This helps you build robust and efficient crushing systems tailored to your needs.

The crushing industry is always evolving. Several key 2025 new trends are influencing crushing plant selection:

These 2025 new trends make the choice between open and closed circuits even more strategic. Modern closed circuits can integrate these technologies more easily for optimal results and future adaptability.

Choosing the ideal crushing system is a complex decision. There are many variables to consider for your unique project. You need to balance initial costs, operational expenses, product quality, and future flexibility. If you are still weighing your options between open-circuit crushing and closed-circuit crushing, I encourage you to reach out.

As ZONEDING, we have over 30 years of experience in stone crusher plant design. Our team of 15 expert engineers provides tailored solutions. We analyze your specific raw material, desired output, budget, and site conditions. We guide you through every step. This includes conceptual design to equipment selection. We also cover installation and ongoing support. Let us design an optimal crushing setup that maximizes your efficiency and profitability.

Contact ZONEDING today for a personalized consultation.

Everything you need to know about pebble sand manufacturing. From selecting the right pebbles to configuring your equipment line and calculating your ROI.

View detailsLooking for the best rock crusher for gold? Our guide compares Jaw, Cone, and Hammer Mill crushers to maximize your gold recovery from hard rock.

View detailsEverything you need to know about Galena (Lead Sulfide). This guide covers its identification, geological properties, and how to process it. Read More!

View detailsThink you know cone crusher liners? Our blog reveals surprising facts about selection, wear, and replacement that could save you time and money.

View details