Galena is one of the most important and recognizable minerals in the world. As the primary source of lead and a significant source of silver, it is fundamental to many industries. At my company, ZONEDING, we have specialized in building complete mineral processing plants since 1990, and we have extensive experience designing systems to efficiently process Galena ore. This guide will share our practical knowledge, explaining what Galena is, its key properties, how to process, and how to handle it safely.

Table of Contents

What is Galena?

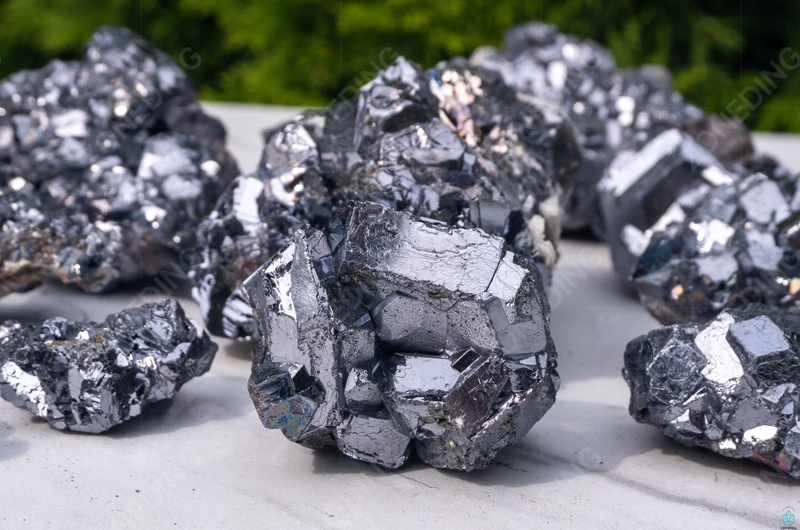

Galena is a natural mineral compound lead sulfide, and it is the world’s most important ore of lead. It is easily one of the most abundant sulfide minerals on Earth. You can recognize it almost instantly by its brilliant, silver-like metallic luster and its tendency to break into perfect cubes. This unique breakage pattern is “cubic cleavage”. For centuries, Galena has been the main source for lead, a metal that has shaped human history, and it often contains enough silver to be a primary ore for that precious metal as well.

What are the Properties of Galena?

Understanding the physical properties of Galena is key to identifying it in the field and designing a plant to process it. These properties are very consistent.

- Color: Bright silver-gray. When exposed to air for a long time, the surface can tarnish to a dull gray.

- Luster: Bright and metallic, like freshly broken lead.

- Cleavage: This is its most famous property. It has perfect cleavage in three directions, at 90-degree angles. This means if you hit it with a hammer, it will shatter into smaller, near-perfect cubes.

- Hardness: It is very soft, with a Mohs hardness of only 2.5. You can easily scratch it with a copper coin. This softness makes it easy to crush.

- Density: Galena is extremely dense. Its specific gravity is about 7.5, meaning it is 7.5 times heavier than water. A small cube of Galena will feel surprisingly heavy in your hand.

- Streak: If you scratch Galena on an unglazed porcelain plate, it will leave a lead-gray to black streak.

What is the Composition of Galena?

The chemical formula for pure Galena is PbS, which stands for lead sulfide. By weight, it is about 86.6% lead and 13.4% sulfur.

However, Galena is a complex ore. It almost always contains small amounts of other elements. The most important of these is silver. Silver atoms can substitute for lead atoms in the crystal structure. Sometimes, a Galena ore can contain enough silver to be more valuable for its silver content than for its lead. This is why many “lead mines” are actually primary silver mines.

Galena is typically formed through hydrothermal processes. This happens when hot, mineral-rich water from deep within the Earth’s crust moves up through cracks and fissures in cooler rock layers. This hot fluid carries dissolved lead, sulfur, and other metals.

As the fluid cools or the pressure changes, these dissolved minerals can no longer stay in the solution. They begin to crystallize and deposit on the walls of the fractures, often forming veins. Galena is commonly found in these veins alongside other minerals like quartz, sphalerite (zinc ore), pyrite, and fluorite. It is most often found in medium-to-low temperature hydrothermal deposits.

Where Can We Find Galena?

Galena is in mineral deposits all over the world. Some of the most significant mining districts are:

- United States: The Mississippi Valley-type deposits, particularly in Missouri, have been a major source. Idaho and Colorado are also famous for silver-rich Galena.

- Australia: The mines at Broken Hill and Mount Isa are massive deposits of lead, zinc, and silver, with Galena being a primary ore.

- Mexico: Mexico is a world-leading producer of silver, much of which is from Galena.

- Canada: The Sullivan Mine in British Columbia was one of the largest lead-zinc-silver producers for nearly a century.

- China and Peru: These countries are also major modern producers of lead and silver from Galena ore.

What are the Applications of Galena?

Because Galena is the primary source of lead, its uses are tied to the applications of lead metal. The main modern and historical uses include:

- Lead-Acid Batteries: This is by far the largest use of lead today. Over 80% of all lead produced goes into the batteries that start our cars.

- Radiation Shielding: Lead is extremely dense, making it excellent at blocking X-rays and gamma rays. It is used to protect people in hospitals, nuclear power plants, and industrial X-ray facilities.

- Electronics: Lead is used in solder to connect electronic components on circuit boards.

- Ammunition: Lead has been used for bullets and shot for centuries.

- Historical Uses: Ancient Romans used lead for water pipes (the word “plumbing” comes from the Latin word for lead, plumbum). Ancient Egyptians used ground Galena as an eyeliner called kohl.

Can Processing Galena Be a Profitable Business?

Yes, processing Galena can be a very profitable business, but success depends on several key factors. The profitability is not just about the lead content. Often, the silver content is the main economic driver. A small amount of silver per ton of ore can dramatically increase the value of your final product.

The key variables that determine profitability are:

- Ore Grade: The percentage of lead and the amount of silver (in grams per ton) in your ore.

- Market Prices: The global prices for lead and silver fluctuate daily.

- Processing Efficiency: This is where we at ZONEDING come in. The efficiency of your plant determines your recovery rate—how much of the metal you successfully extract. A more efficient plant with higher recovery rates directly translates to higher profits.

- Operational Costs: Expenses for energy, water, labor, and chemical reagents must be carefully managed.

How To Process the Galena Ore?

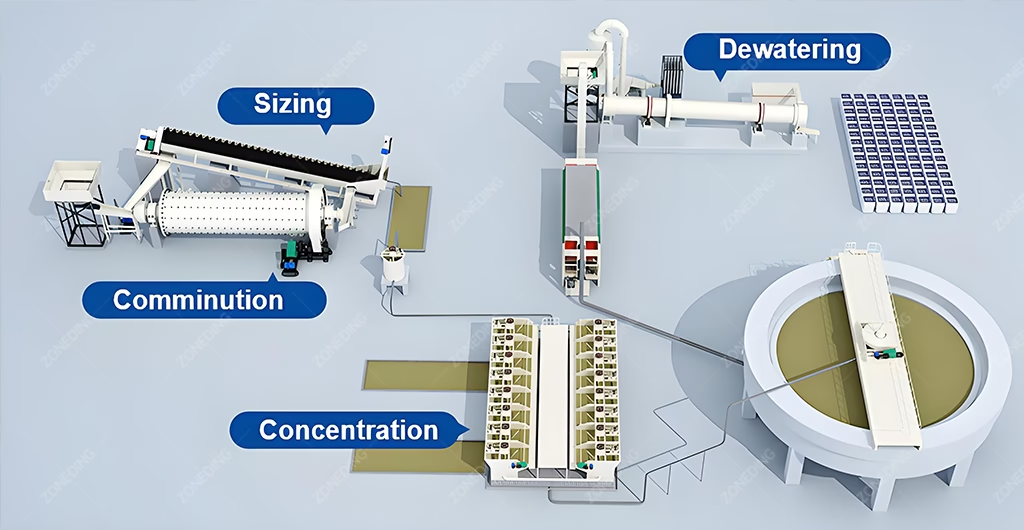

Processing Galena to extract lead and silver is a well-established industrial process. At ZONEDING, we design entire plants based on these steps. The journey from rock to metal involves several stages:

- Crushing and Grinding: The large rocks of ore from the mine must first be broken down. Crushers reduce the size to a few centimeters, and then grinding mills (like ball mills) pulverize the rock into a fine powder, the consistency of sand. This is done to “liberate” the Galena particles from the worthless host rock.

- Froth Flotation: This is the most common method to concentrate Galena. The fine ore powder is mixed with water and specific chemical reagents in flotation cells. Air is bubbled through the mixture. The reagents make the Galena particles stick to the air bubbles and float to the surface, where they are skimmed off as a rich concentrate. This process can separate Galena from other minerals like zinc sulfide (sphalerite).

- Dewatering: The foamy concentrate from flotation is mostly water. It is sent to a thickener, which allows the solids to settle, and then to a filter to remove most of the remaining water, creating a dense, damp cake.

- Smelting: The concentrate is then heated in a furnace to very high temperatures. This process removes the sulfur (which is released as sulfur dioxide gas) and melts the lead, which sinks to the bottom. The silver follows the lead into this molten metal, which is then cast into bars.

What are Essential Equipment in the Galena Processing Plant?

A typical Galena processing plant requires a series of robust machines working together. We manufacture this entire line of equipment at ZONEDING.

- Jaw Crusher: For the primary stage of breaking large rocks.

- Cone Crusher: For the secondary stage, making smaller rocks from the jaw crusher’s output.

- Ball Mill: A rotating drum filled with steel balls that grinds the crushed rock into a fine powder.

- Flotation Cells: Large tanks where the separation of Galena from waste rock occurs.

- Thickeners and Filters: To remove water from the valuable concentrate.

- Smelting Furnace: To melt the concentrate and produce lead metal.

What are the Key Difficulties When We Process Galena?

Processing Galena is not always straightforward. There are common challenges that we help our clients solve with custom-designed solutions.

- Complex Ores: Galena is often found mixed with other valuable minerals, especially sphalerite (zinc ore). The trick is to separate them.

- Solution: We use a technique called “differential flotation.” By carefully controlling the chemistry (pH and reagents) in the flotation cells, we can float the Galena first, collect it, and then change the chemistry to float the sphalerite in a separate step.

- Fine-Grained Silver: Sometimes the silver is present as microscopic particles. If grinding is not fine enough, these particles remain locked inside the Galena and are not recovered efficiently.

- Solution: The ore needs to be ground to an ultra-fine size. This requires careful selection of the grinding mill and classification system to ensure the particles are fully liberated before flotation.

- Tarnishing (Oxidation): If the Galena is exposed to air and water for too long, its surface can oxidize. This makes it less responsive to flotation reagents, lowering recovery rates.

- Solution: The time between grinding and flotation should be minimized. Sometimes, specific activating reagents are needed to clean the mineral surface before flotation.

Is Galena Dangerous to Touch and Handle?

This is a very important question. The answer requires some clarification. Simply touching a solid, stable piece of Galena is generally considered low risk for a short period. The lead is chemically bonded with sulfur, making it stable.

However, the primary danger comes from Galena dust. When Galena is broken, crushed, or ground, it creates fine dust. If you inhale or ingest this dust, the lead can be absorbed into your body, leading to lead poisoning, which is a serious health condition. Therefore, while touching a smooth crystal is not highly dangerous, any activity that creates dust makes handling Galena hazardous.

What are the Essential Rules for Safely Handling Galena?

Anyone working with Galena, from geologists to plant operators, must follow strict safety rules to prevent lead exposure.

- Wear Gloves: While brief contact is low risk, it’s best practice to wear gloves to avoid prolonged skin contact and prevent dust from getting on your hands.

- Use Respiratory Protection: If there is any chance of dust being created, a properly fitted respirator or dust mask is absolutely essential.

- Wash Your Hands Thoroughly: Always wash your hands with soap and water after handling Galena, especially before eating, drinking, or smoking.

- Work in a Well-Ventilated Area: Good airflow helps to disperse any airborne dust.

- Control Dust: Use water sprays (wet methods) during crushing or cutting to keep dust from becoming airborne.

Why Choose ZONEDING?

Since 1990, ZONEDING has been a global leader in manufacturing robust and efficient mineral processing machinery.

We provide much more than just individual pieces of equipment; we deliver complete, custom-engineered, “one-stop” solutions. Our team of 15 professional mining engineers will work with you to design a full Galena processing plant tailored to your specific ore characteristics and business goals. As a factory-direct manufacturer, we eliminate middleman costs, offering you superior quality and value.Having exported to over 120 countries, we have the deep global experience to ensure your project is a success, from initial design and installation to operator training and long-term after-sales support.

FAQ

- How can you identify the Galena mineral?

- Look for three key things: a brilliant silver-like metallic luster, a very high density (it feels extremely heavy for its size), and its tendency to break into perfect cubes (cubic cleavage).

- Is Galena toxic to handle?

- The main toxicity risk is not from touching a solid piece but from inhaling or ingesting the dust created when it is broken or crushed. The lead in the dust is hazardous and can cause lead poisoning.

- What is the metaphysical meaning of Galena?

- In spiritual and metaphysical circles, Galena is considered a grounding stone. It is believed to bring balance, harmony, and stability, helping to anchor a person’s energy and center their mind.

Contact our expert team today for a free consultation and a customized quote for your Galena processing needs.