Starting a quarry business can be a profitable venture. Quarries supply essential raw materials like aggregates, sand, and crushed stone. These materials drive construction, infrastructure, and development. This business requires careful planning, significant investment, and adherence to many regulations. This comprehensive guide breaks down the process into clear, manageable steps. It provides a roadmap for successfully starting a quarry business. ZONEDING, a leading manufacturer of mining and quarrying machinery, understands the intricate needs of this industry.

Table of Contents

What Are the Key Steps to Start Your Quarry?

Starting a quarry business involves a series of critical steps. Each step builds upon the last. Operators must approach this methodically. This ensures a solid foundation for the operation. Skipping any step can lead to significant problems later. Careful planning is essential for a successful quarry business.

Conduct a Feasibility Study:

Before investing, operators must confirm the business idea’s viability. This study involves thorough market research. It assesses the demand for quarry products in the chosen region. Operators should examine current and future construction projects. They must analyze potential competitors. Their pricing and capacity need understanding. Crucially, geologists must evaluate potential sites. They check for geological suitability and mineral reserves. This step determines if the quarry business has a market and a viable resource.

- Market Analysis: Understand who needs the products and how much they will pay.

- Resource Assessment: Confirm the quality and quantity of rock or sand deposits.

- Environmental Review: Identify potential environmental challenges and costs.

- Financial Projections: Estimate startup and operating costs, and potential revenue.

Develop a Comprehensive Business Plan:

A detailed plan guides operations. It helps secure financing. This plan outlines business goals and strategies. It defines the target market and operational processes. It should include financial projections with startup costs, operating expenses, and revenue forecasts. The business plan serves as a formal document. It is critical for investors and banks. It demonstrates thorough consideration of every aspect of the quarry business.

Navigate Legal and Permitting Requirements:

This is a lengthy but mandatory process. Operators must obtain several permits and licenses. These relate to environmental impact, land use, mining rights, and operational safety. Regulations vary significantly by location. Both local and national requirements must be understood. Failing this can lead to penalties and operational shutdowns. Patience and thoroughness are key here. ZONEDING understands how critical regulatory compliance is. Its specialized crushing equipment meets necessary operational standards.

Select the Right Site:

Location holds paramount importance for a quarry business. The site must offer significant, high-quality reserves. It needs good access to transportation networks. Proximity to target markets reduces hauling costs. Operators should consider site size, topography, and potential environmental impacts. Ensure the site allows access for heavy machinery and trucks. A well-chosen site significantly reduces long-term operational costs.

Acquire Essential Equipment:

Quarrying requires specialized heavy machinery. This includes excavators, loaders, crushing equipment, screening plants, and dump trucks. The scale of operation determines the type and quantity of machinery. Operators can purchase, lease, or rent equipment. Quality and reliability remain crucial for minimizing downtime. This represents one of the largest capital expenditures for a quarry business.

Set Up Operations and Marketing:

Once permits and equipment are in place, operations can begin. This involves hiring and training staff. Operators must implement strict safety protocols. They need to establish efficient production processes. Simultaneously, they must develop a marketing strategy. Build relationships with construction companies, road builders, and local municipalities. Marketing defines how a quarry sells its products.

Each step requires dedication. It needs a clear understanding of the industry. This step-by-step approach sets up for success in the quarry business.

What Permits and Regulations Do You Need?

Navigating the legal and regulatory landscape represents one of the most complex parts of starting a quarry business. Permits ensure operations comply with environmental and safety standards. Skipping this can lead to severe fines or closure. Understanding the specific permits required remains vital. They protect both the business and the environment.

Quarries often involve large-scale land alteration, dust, noise, and water management. Regulatory bodies oversee these activities. They ensure responsible operation. The exact permits needed vary by country, state, or even local municipality.

However, common categories include:

Land Use Permits and Zoning Clearances:

The chosen site must be zoned for quarrying. Operators need a permit for using the land for mining. This often involves planning permission from local authorities. It protects surrounding communities from industrial impact.

Operators need permission to extract minerals from the ground. This could involve a lease from the landowner or a license from a government mining authority. This permit specifies what can be extracted and how much.

Environmental Impact Assessment (EIA) and Permits:

This often constitutes the most extensive and time-consuming permit. An EIA evaluates the potential environmental effects of the quarry. This includes impacts on air quality, water resources, noise levels, biodiversity, and land stability. Based on the EIA, operators will need permits for:

- Air Quality Permits: These control dust emissions from drilling, blasting, crushing, and hauling.

- Water Management Permits: These manage water abstraction, discharge, runoff, and wastewater treatment. This safeguards local water bodies.

- Noise Permits: These control noise levels, especially if the quarry operates near residential areas.

- Reclamation Permits: These outline how operators will restore the land after quarrying ends. This includes backfilling, landscaping, and planting.

Health and Safety Permits:

Operations must comply with occupational health and safety regulations. This ensures a safe working environment for employees. This includes permits for explosives handling, machinery operation, and general site safety.

Traffic and Transportation Permits:

Large trucks will access the site. Operators might need permits for truck routes. Permits are also needed for any road modifications to handle heavy vehicle traffic.

Waste Management Permits:

This covers the disposal of any non-mineral waste generated by operations. This ensures proper handling of all refuse.

The process for obtaining these permits often involves:

- Application Submission: Operators fill out detailed forms with technical data.

- Public Hearings: Local community members may voice concerns or support.

- Expert Reviews: Government agencies review plans and studies.

- Compliance Monitoring: Once approved, regular inspections ensure adherence to permit conditions.

It is highly advisable to consult environmental consultants and legal experts specializing in mining and quarrying. They can guide operators through this complex process efficiently. ZONEDING, a seasoned manufacturer with a global presence, understands these varied regulatory environments. The company can advise on equipment specifications that meet common international compliance standards.

What Essential Machines Does a Quarry Business Need?

The core of any quarry business lies in its machinery. Operators need robust, reliable equipment to extract, process, and transport material efficiently. Investing in the right machines directly impacts productivity and profitability. High-quality machinery reduces downtime. It also ensures consistent product quality.

Here are the essential machines for a quarry business:

Excavation Equipment:

- Excavators: These machines dig and load overburden (waste material) and raw aggregate. They come in various sizes, depending on the scale of the quarry.

- Wheel Loaders: These versatile machines load trucks, feed crushers, and move materials around the site. They are crucial for moving large volumes quickly.

Drilling and Blasting Equipment (for hard rock quarries):

- Drill Rigs: Operators use these to bore holes into hard rock for placing explosives. These are essential for breaking up large rock formations.

- Compressors: These provide air for drill rigs or other pneumatic tools. Blasting expertise is critical for safety and efficiency.

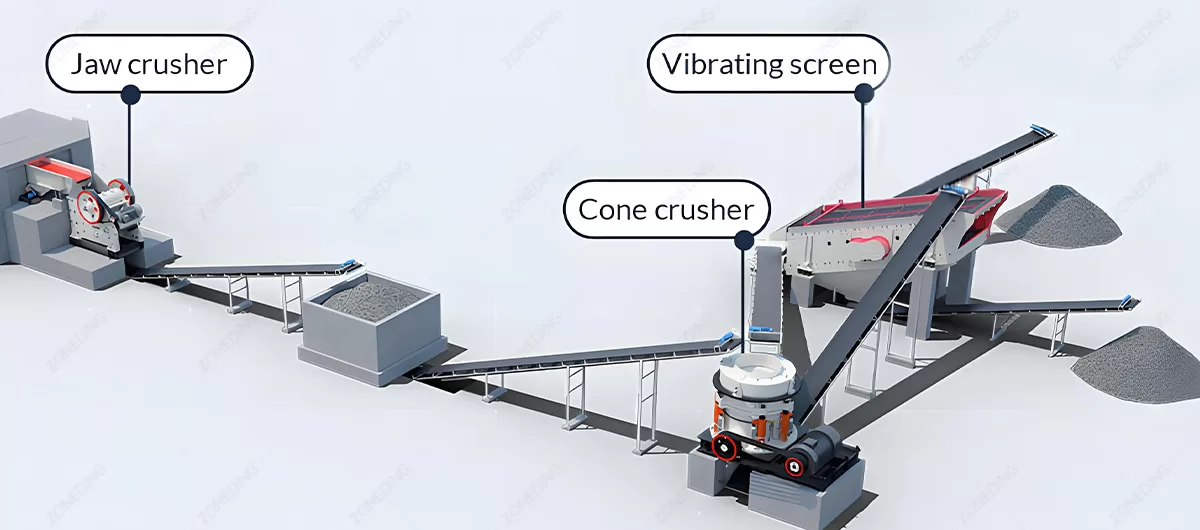

Crushing Equipment:

This equipment forms the heart of aggregate production.

- Jaw Crushers: These are primary crushers. They take large rocks from the quarry face. They reduce them to smaller, manageable sizes. ZONEDING’s crushing equipment features robust jaw crushers capable of handling extremely hard materials.

- Cone Crushers: These serve as secondary or tertiary crushers. They take the output from jaw crushers. They reduce rock to even finer, more consistent sizes. And They are ideal for producing aggregates with specific shapes.

- Impact Crushers: Operators use these for crushing medium-hard, non-abrasive materials. They produce well-shaped aggregates. They also find wide use in recycling applications (e.g., concrete). ZONEDING manufactures various crushers. Producers design them for high throughput and consistent product quality.

Screening Equipment:

- Vibrating Screens: After crushing, material moves through screens. These separate aggregates into different size fractions. They ensure consistent product grading. Screens are crucial for meeting customer specifications.

Conveying Equipment:

- Belt Conveyors: These move material efficiently between different stages of the crushing and screening plant. They transport crushed stone from one crusher to another, or to stockpiles. ZONEDING provides durable belt conveyors that can handle various materials and volumes. Producers design them for long-term, continuous operation.

Hauling Equipment:

- Dump Trucks (and Articulated Haulers): These transport raw material from the quarry face to the primary crusher. They also move final products to stockpiles or directly to customers. The fleet size depends on the quarry’s output.

Specialized Equipment:

- Mobile Crushing Stations: These integrate crushing, screening, and conveying onto a mobile chassis. They offer flexibility. Operators can move them closer to the working face. This reduces internal hauling costs. ZONEDING offers advanced mobile crushing station solutions. They provide efficiency and adaptability, especially for projects with changing site conditions.

- Material Washers: These produce clean aggregates (e.g., sand and gravel). They remove clay and other impurities.

When selecting machinery, focus on reliability, fuel efficiency, and ease of maintenance. ZONEDING’s extensive experience from 1990 in manufacturing quarrying machinery makes it a key supplier. The company uses high-wear steel and reputable global component brands. This ensures its machines provide long service life and high performance, critical for a quarry business.

How Much Does It Cost to Start a Quarry Business?

The cost of starting a quarry business can be substantial. It varies greatly depending on the scale, location, and type of materials operators plan to extract. Operators must clearly understand these costs. This ensures adequate funding for the venture. This remains a capital-intensive industry.

Here’s a breakdown of typical costs:

Land Acquisition or Lease:

- Cost Factor: This is highly variable. Rural land with mineral rights will cost less than land closer to urban markets. Leasing can reduce upfront costs but adds ongoing expenses.

- Estimate: Can range from hundreds of thousands to several million dollars, depending on acres and location.

Permits and Legal Fees:

- Cost Factor: Environmental Impact Assessments, mining licenses, land use permits, and legal counsel fees accumulate. This constitutes a significant non-physical cost.

- Estimate: Can range from tens of thousands to hundreds of thousands of dollars. This depends on regulatory complexity and expert involvement.

Equipment Purchase or Lease:

- Cost Factor: This often represents the largest expense. Operators need a full fleet of excavators, loaders, crushers, screens, conveyors, and trucks. New equipment is costly. Used equipment can save money but might increase maintenance. Leasing can spread costs.

- Estimate: From a few hundred thousand dollars for a small, basic operation with used equipment to several million for a large, modern plant with new machinery. ZONEDING’s range of crushing equipment and mobile crushing stations offers various budget options.

Site Development and Infrastructure:

- Cost Factor: This includes preparing the quarry site. It involves road construction, utility installation (power, water), office buildings, workshop facilities, weighing stations, and environmental controls (e.g., settling ponds).

- Estimate: From tens of thousands to hundreds of thousands of dollars.

Operational Costs (Initial Phase & Working Capital):

- Cost Factor: Funds are needed for ongoing expenses before revenue stabilizes. This includes:

- Labor: Wages for operators, maintenance staff, management.

- Fuel & Lubricants: For all heavy machinery. This is a major ongoing cost.

- Maintenance & Parts: Regular servicing and spare parts remain essential. ZONEDING designs its machinery with high-quality components. This ensures reduced maintenance costs over the long term.

- Blasting Supplies: Explosives, if applicable.

- Insurance: Liability and equipment insurance.

- Utilities: Electricity, water for the site.

- Marketing & Sales: Initial efforts to secure customers.

- Estimate: Operators need several months of operating expenses in reserve. This could amount to hundreds of thousands of dollars or more.

Starting a quarry business requires substantial capital. Operators must secure robust financing. This might involve bank loans, investor funding, or a combination. A detailed financial plan is crucial for presenting to potential funders. It demonstrates an understanding of the investment required for a quarry business.

How to Conduct Market Analysis for a Quarry Business?

A thorough market analysis is essential for any successful quarry business. It helps operators understand who their customers are. It also helps grasp what they need and how much they will pay. This analysis guides production and sales strategies. Without it, operators might produce the wrong product or struggle to find buyers.

Here’s how to conduct effective market analysis for a quarry business:

Identify Target Customers:

- Construction Companies: These are primary clients. They need aggregates for roads, buildings, and foundations. Operators should segment them by size (small local builders vs. large contractors).

- Infrastructure Projects: Government contracts for roads, bridges, airports, and dams consume huge volumes of quarry products. Operators should monitor major upcoming public works.

- Concrete and Asphalt Plants: These often serve as direct consumers of specific types and sizes of aggregates as raw materials for their products.

- Landscaping and Residential Projects: These involve smaller volumes but can add up. They use decorative stones, gravels, and sand.

- Municipalities: For local road maintenance, public works, and specific projects.

Assess Demand and Market Size:

- Current Demand: Operators should research statistics on construction spending, road projects, and housing starts in their region. Local economic development reports are valuable.

- Future Demand: Planned developments should be examined. Operators need to anticipate where future growth will occur. Population trends and industrial expansion should be considered.

- Product Specific Demand: Operators should determine the specific types of aggregates most needed (e.g., crushed stone, sand, gravel, specific sizes). Do certain projects require specialty products?

Analyze Competition:

- Identify Competitors: Operators should list all existing quarries in their target market area.

- Capacity and Production: They should estimate competitors’ output volumes. Do competitors have excess capacity?

- Pricing Strategy: Operators should understand competitors’ current pricing for different products. This helps position one’s own pricing.

- Product Quality and Specialization: Do competitors offer unique products or higher quality?

- Logistics and Distribution: How do competitors transport their products? What are their delivery capabilities?

- Reputation: What is competitors’ standing in the market? Operators should identify strengths and weaknesses.

Develop Pricing Strategies:

- Cost-Plus Pricing: Operators should calculate their production and operational costs, then add a profit margin.

- Market-Based Pricing: Products should be priced competitively based on what others charge. Adjustments should be made for quality or unique services.

- Value-Based Pricing: If a product or service offers superior value (e.g., faster delivery, higher quality), a premium might be charged.

Establish Distribution Channels:

- Direct Sales: Selling directly to construction companies or individuals.

- Brokerage/Wholesale: Selling through middlemen or to larger distributors.

- Long-Term Contracts: Securing agreements with major projects or ongoing buyers. This provides stability.

Market analysis should be ongoing. The construction market changes. New projects emerge. Competitors adapt. The market position should be regularly reviewed. ZONEDING’s experience exporting to over 120 countries gives it a broad view of diverse market demands for heavy machinery. This global market understanding can indirectly inform local market strategies for a quarry business.

What Advice is Best for New Quarry Business Starters?

Starting a quarry business is a marathon, not a sprint. New operators need practical advice to navigate the challenges. Focus on a few key areas. This will lay the groundwork for long-term success. These tips help avoid common pitfalls. They also help build a resilient business.

- Prioritize Safety Above All Else: Quarrying is inherently dangerous. Operators must implement stringent safety protocols from day one. Investment in proper safety training, personal protective equipment (PPE), and regular safety audits is necessary. A strong safety culture protects workers. It also prevents costly accidents and legal issues. The ZONEDING company emphasizes safety in its designs and production. Its robust equipment features operator safety in mind.

- Start Smaller and Scale Up: Do not overcommit on initial investment. Operators should begin with a manageable operation size. They need to learn the ropes. As the market expands and the team gains experience, production capacity can be increased. ZONEDING’s customization capabilities mean operators can start with a basic setup. They can then gradually integrate more advanced crushing equipment or even a mobile crushing station as their business grows. This flexibility is crucial.

- Forge Strong Relationships:

- Customers: Trust should be built by consistently delivering quality products on time. Long-term contracts offer stability.

- Suppliers: Good relationships with equipment, fuel, and blasting suppliers can lead to better pricing and service.

- Local Community: Be a good neighbor. Address concerns. Contribute positively. This fosters goodwill and can ease regulatory processes.

- Master Maintenance and Operations: Downtime costs in a quarry. Operators must implement a rigorous preventive maintenance schedule for all machinery. They need to train operators well. Efficient operation reduces wear and tear. It also maximizes throughput. Utilize ZONEDING’s full-service support, which includes installation, debugging, and personnel training. This ensures the team can operate and maintain equipment effectively from the start.

2025 Trends Shaping the Quarry Business?

The quarry business undergoes significant transformations. Several key trends are emerging in 2025. These trends are driven by technological advancements, environmental concerns, and economic pressures. Operators need to understand these to maintain competitiveness. Adapting to these changes is not optional. It is essential for future success.

Key Developments in Quarry Operations

- Increased Automation and Digitalization: Quarries are becoming smarter. Automation in drilling, crushing, and conveying systems reduces labor costs. It improves efficiency. Digital tools enhance site management. This includes drone surveys, GPS-guided machinery, and advanced software for production planning. ZONEDING integrates Siemens PLC control cabinets and sensors into its machinery. This supports intelligent operation in modern quarries.

- Focus on Sustainability and Circular Economy: Environmental regulations are getting stricter. There is a growing demand for sustainable practices. Quarries are adopting better water management, dust suppression, and rehabilitation techniques. The idea of a “circular economy” gains traction. This involves processing construction and demolition waste into new aggregates. This reduces landfill waste. It also creates new revenue streams for a quarry business.

- Advanced Materials and Equipment Design: New materials make quarry equipment more durable and efficient. High-wear-resistant steel and composite materials extend the lifespan of crusher wear parts. They reduce maintenance downtime. Equipment designs prioritize fuel efficiency and lower emissions. ZONEDING uses high-wear steel and globally recognized component brands. This ensures its machinery meets these higher performance and durability standards.

- Modular and Mobile Plant Solutions: Flexibility becomes crucial. Mobile crushing stations and modular plant designs allow operators to move processing closer to the extraction face or to different sites. This reduces internal hauling costs. It also enables quicker setup and adaptation for varied project needs. This aligns with ZONEDING’s focus on customizable solutions that adapt to specific client requirements.

- Data-Driven Decision Making: Real-time data from machinery and production lines becomes standard. Analytics platforms help quarry managers make informed decisions. They optimize production flow, predict maintenance needs, and manage inventory more effectively. This allows for continuous improvement in a quarry business.

FAQ

- Question 1: What are typical profit margins for a quarry business?

- Profit margins vary. They depend on location, product type, competition, and operational efficiency. They can range from 10% to 30% or more. High demand areas with limited competition often yield better returns.

- Question 2: How long does it take to start a quarry business?

- The timeline is extensive. It can take anywhere from 2 to 5 years, or even longer. Permitting and environmental assessments often consume the longest part of the process. Site development and equipment acquisition also take considerable time.

- Question 3: What are the biggest environmental impacts of a quarry?

- Major impacts include dust and noise pollution, water pollution (runoff, sediment), habitat destruction, and landscape alteration. Proper mitigation and reclamation plans are crucial for managing these impacts.

- Question 4: What is the most important factor for success in the quarry business?

- Strategic location with abundant, high-quality reserves close to a strong market demand is paramount. This, combined with efficient operations and robust equipment, often determines success.

- Question 5: Can ZONEDING assist with setting up a full quarry production line?

- Yes, ZONEDING provides full-service support. This includes scheme design, equipment manufacturing, installation, debugging, and personnel training for complete production lines. The company offers one-stop solutions for client needs.

Conclusion

Starting a quarry business is a complex but rewarding endeavor. It demands careful planning, significant investment, and strict adherence to regulations. This guide has outlined the essential steps. These include conducting a thorough feasibility study, developing a robust business plan, and navigating the extensive permitting process. Operators must deeply understand the quarry machines required. They also need to manage the substantial quarry cost. A comprehensive market analysis is critical for identifying demand and competition.

The recommendation for new starters is to prioritize safety, start small, and build strong relationships. Operators should embrace environmental responsibility. They must stay agile. The industry is evolving with trends like automation and sustainability. By leveraging ZONEDING’s customized solutions and full-service support, operators can equip their quarry business with high-quality crushing equipment and mobile crushing stations. This provides a strong foundation for efficiency and long-term profitability.