Understanding different gold ore types is fundamental for successful mining. The geology of a gold deposit directly dictates how to mine it and how to extract the gold. This knowledge influences every decision, from initial exploration to final recovery. It impacts a project’s profitability. At ZONEDING, the company has been working to improve mineral processing for over 30 years. ZONEDING understands how crucial it is to match the right equipment to the right ore. The company aims to help you make better decisions for your operations.

Table of Contents

What Are the Main Types of Gold Ore Formations?

Gold ore formations vary greatly across the earth. Geologists categorize them based on how they form and where they are. These categories help understand how to approach mining them. Knowing the primary types is the first step. It directs the entire mining plan effectively. These different formations present engineering challenges. Each one needs a specific type of solution.

The two broad categories are primary (lode) deposits and secondary (placer) deposits.

Primary (Lode) Gold Deposits:

This gold is in embedded within rock formations. It occurs where gold-bearing fluids, often hot, have traveled through fractures and faults in the Earth’s crust. As these fluids cooled, gold precipitated out along with other minerals.

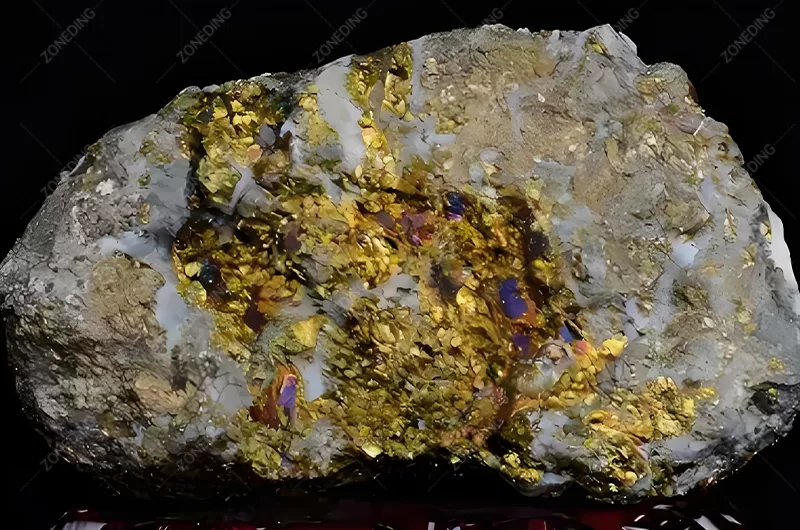

- Vein Deposits: These are perhaps the most iconic. Gold is in quartz veins that cut through host rock. The gold can be free-milling (visible) or microscopic within the quartz. Sometimes it is with sulfides like pyrite. These deposits often require hard rock mining techniques.

- Disseminated Deposits: Here, gold particles are spread throughout a large volume of rock. The gold content is often low, but the sheer volume of rock makes them economically viable. They often form in areas of intense alteration, like porphyry-style deposits. Mining these typically involves large-scale bulk mining.

- Skarn Deposits: These form at the contact zones between igneous intrusions and carbonate-rich sedimentary rocks. Gold can be present with sulfide minerals. These deposits are often complex. They require careful metallurgical testing.

- Epithermal Deposits: These are closer to the surface at lower temperatures. Gold often occurs as fine particles or electrum (gold-silver alloy). These can be high-grade deposits but are often structurally complex.

Secondary (Placer) Gold Deposits:

This gold forms when primary gold deposits are eroded by wind and water. The heavier gold particles are then transported and deposited in riverbeds, deltas, or coastal areas.

- Alluvial Placer Deposits: This is gold in river gravels, sand, and ancient streambeds. The gold is typically coarser here and often occurs as flakes or nuggets. It is usually near the surface.

- Eluvial Placer Deposits: This gold is near the original primary source rock. It has not traveled far from where it formed. It might be mixed with weathered rock fragments.

- Beach Placer Deposits: Wave action concentrates heavy minerals, including gold, on beaches or ancient shorelines. This is common in certain coastal regions.

How Do Gold Ore Types Influence Mining Strategies?

The type of gold ore dictates the entire mining strategy. Mining methods must be chosen that physically access the gold. These methods must be safe, cost-effective, and environmentally responsible. The right strategy minimizes waste. It maximizes gold recovery from the ground. An incorrect mining approach can waste significant resources.

Mining Strategies for Primary (Lode) Deposits

Lode deposits are hard rock formations. They demand specific mining techniques:

- Underground Mining (for vein or deep deposits):

- Challenge: Gold lies deep underground in narrow veins or disseminated within hard rock. Strategy: Workers dig tunnels, shafts, and drifts to reach the ore body. Specialized drilling and blasting techniques are important to break the rock. Then, loaders and trucks remove the ore. This method is often costly and complex.However, it can access high-grade ore. ZONEDING provides robust equipment for these operations. Its large cutting machines and lifting equipment are essential for fabricating support structures and managing heavy loads in underground environments.

- Open-Pit Mining (for disseminated or large low-grade deposits):

- Challenge: Gold is spread over a large area but at low concentrations. It is closer to the surface.

- Strategy: Layers of waste rock and ore are removed in benches. This forms a large, stepped pit. It involves massive earth-moving equipment like excavators and haul trucks. Blasting is also common. This method is cost-effective for large volumes of low-grade ore. It requires significant planning for material handling. ZONEDING’s experience in designing complete processing lines for mineral factories means it can integrate high-capacity equipment, like conveying systems, for moving vast amounts of material efficiently in such large-scale operations.

Mining Strategies for Secondary (Placer) Deposits

Placer deposits involve looser, unconsolidated materials. They rely on different mining approaches:

- Dredging (for alluvial deposits in water bodies):

- Challenge: Gold is in riverbeds or underwater.

- Strategy: Large floating dredges scoop up gravel and sand from the bottom. They process it on board to separate the gold. This is efficient for large-scale alluvial deposits. It requires careful environmental management.

- Panning & Sluicing (for smaller alluvial deposits):

- Challenge: Gold in shallow streambeds or small surface deposits.

- Strategy: These are simpler, often artisanal methods. Panning uses water to wash away lighter materials, leaving gold behind. Sluicing uses a long box with riffles to catch gold. These are low-cost but labor-intensive. They are suitable for small operations.

- Dryland Placer Mining (for desert or ancient riverbeds):

- Challenge: Gold in dry gravels where water is scarce.

- Strategy: Uses air or limited water to separate gold from lighter materials. Specialized dry concentrators can achieve this. It needs careful dust control.

What Are the Key Gold Extraction and Beneficiation Processes?

This involves various beneficiation processes. These processes separate gold from waste rock. The choice of process depends heavily on the ore type and how the gold is present. ZONEDING’s 15 specialized mineral processing engineers often say, “Every ore type tells a story about its optimal processing path.” Choosing the wrong path can lead to significant losses.

The main processes include:

Crushing and Grinding (Size Reduction):

- Purpose: To reduce the size of the ore particles. This liberates the gold from the surrounding rock.

- Application: Essential for virtually all primary (lode) gold deposits.

- Process: Jaw crushers, cone crushers, and impact crushers handle the initial size reduction. Then, ball mills or rod mills further grind the ore into a fine powder. This fine powder is slurry. The goal is to make the gold particles accessible for subsequent separation stages. ZONEDING excels in this area. Its advanced production equipment, including CNC machines, ensures precision in manufacturing robust crushing and grinding machinery.This prepares it for the next steps. Its machines also use high-wear-resistant steel. This ensures durability in demanding crushing environments.

- Equipment: Jaw crushers, cone crushers, ball mills, rod mills.

Gravity Separation:

- Purpose: To separate gold based on its high density. Gold is much heavier than most waste minerals.

- Application: Highly effective for coarser free gold. This includes most placer deposits and some free-milling lode ores.

- Process: Water flows over specially designed equipment. This equipment includes sluice boxes, jigs, and centrifugal concentrators. The heavy gold particles settle out. Lighter waste material washes away.

- Equipment: Sluice boxes, jigs, shaking tables, centrifugal concentrators.

Flotation:

- Purpose: To concentrate gold-bearing sulfide minerals. Gold is often locked within these sulfides.

- Application: Used for “refractory” ores where gold is finely associated with sulfides.

- Process: The finely ground ore slurry is mixed with frothing agents and collectors. These chemicals make the gold-bearing sulfide particles water-repellent. Air bubbles are introduced. These bubbles attach to the sulfide particles and lift them to the surface. They form a froth that is skimmed off. This concentrates the valuable minerals.

- Equipment: Flotation cells.

Cyanidation (Leaching):

- Purpose: To dissolve gold into a solution. This allows for its chemical recovery.

- Application: Very common for most gold ores, especially fine gold that is not recoverable by gravity or flotation. This includes disseminated and some refractory ores after pre-treatment.

- Process: Gold ore is finely ground. It is then mixed with a dilute cyanide solution. Cyanide forms a complex with gold, dissolving it. The gold-rich solution is then separated from the solid waste. Gold is later recovered from the solution using methods like Activated Carbon Adsorption (CIP/CIL) or Zinc Precipitation (Merrill-Crowe). Modern methods like the ZONEDING automatic block machine feature advanced control systems. These systems can be adapted to manage and monitor chemical processes if they were part of a broader mineral processing setup. This ensures precise control over reagent additions and reaction times.

- Equipment: Leaching tanks, carbon columns, zinc precipitation units.

Smelting and Refining:

- Purpose: To purify the gold concentrate or doré bars.

- Application: The final stage for most gold operations.

- Process: Gold concentrates (from gravity, flotation) or gold (from cyanidation) are melted and refined to remove impurities. This yields high-purity gold bullion.

Each step requires careful monitoring and control. The ore’s specific characteristics, such as particle size, mineralogy, and chemical composition, need to be understood. This ensures the chosen process is effective. For ZONEDING, its range of equipment, including its versatile plate mixers and efficient belt conveyors, fits into various stages of a mineral processing plant. ZONEDING provides full-service support, from initial design to installation and operational training. This ensures your extraction process is optimized.

How Do Different Ore Types Affect Gold Recovery Rates?

Gold recovery rates vary dramatically based on the ore type. This impacts a mine’s profitability directly. These variations must be understood. This helps set realistic expectations. It also guides the choice of suitable technologies. Maximizing recovery for every client is a continuous effort. Even a small percentage increase in recovery can mean significant profit.

Recovery from Placer Deposits

- Characteristics: Gold is typically coarse, free, and not chemically bound to other minerals. It is generally found in unconsolidated material.

- Recovery Method: Primarily gravity separation.

- Recovery Rates: Generally high, often 80% to 95% for coarse gold. Finer gold can be more challenging to recover.

- Challenges: Loss of fine gold due to inefficient separation. Clay content can make separation difficult.

- Impact: Placer deposits are often low-cost to mine. High recovery rates are achievable with efficient gravity circuits.

Recovery from Free-Milling Lode Deposits

- Characteristics: Gold is native, relatively coarse, and encapsulated in quartz or other easily crushed minerals. It is not associated with significant sulfides.

- Recovery Method: Crushing, grinding, gravity separation, and often direct cyanidation.

- Recovery Rates: High, frequently 85% to 98%. Gravity separation recovers coarser gold. Cyanidation collects the finer remaining gold.

- Challenges: Ensuring sufficient liberation of gold through grinding. Preventing losses in tailings.

- Impact: Good recovery rates generally make these deposits attractive. Investment in efficient crushing and grinding is key.

Recovery from Refractory Gold Deposits (with Sulfides)

- Characteristics: Gold is within sulfide minerals (like pyrite or arsenopyrite). It cannot be directly dissolved by cyanide without pre-treatment.

- Recovery Method: Crushing, grinding, flotation (to concentrate sulfides), then often oxidative pre-treatment (roasting, bio-oxidation, pressure oxidation), followed by cyanidation.

- Recovery Rates: Variable, often 60% to 90%, depending on the complexity of the ore and the effectiveness of pre-treatment. These rates are lower than free-milling ores.

- Challenges: The cost and complexity of pre-treating the sulfide concentrate. Environmental management of sulfur dioxide (from roasting) or arsenic.

- Impact: Mining these deposits is more capital-intensive due to the need for advanced processing. However, they can contain vast gold resources. ZONEDING’s expertise in specialized mineral processing ensures its equipment, such as durable mixing equipment designed for harsh chemical environments, can handle the tough requirements of refractory ore processing.

Recovery from Ultra-Fine or Microscopic Gold Deposits

- Characteristics: Gold present in extremely fine particles. It might be chemically bound within certain mineral matrices.

- Recovery Method: Highly specialized grinding to ultra-fine levels. Advanced leaching techniques.

- Recovery Rates: Often lower, potentially 50% to 80%, as complete liberation and recovery of ultra-fine gold are challenging.

- Challenges: High energy consumption for ultra-fine grinding. Difficulties in separating very fine particles.

- Impact: These deposits require cutting-edge technology and substantial operational costs.

What Are the Latest Trends in Gold Mining Technology?

The gold mining industry is constantly evolving. It is driven by the need for higher efficiency, lower environmental impact, and safer operations. New technologies are emerging. They provide innovative solutions to long-standing challenges. ZONEDING keeps a close watch on these trends. This ensures ZONEDING’s equipment remains at the forefront.

Latest Developments Shaping Gold Mining

- Automation and Robotics: Mines are becoming increasingly automated. Automated drilling, blasting, and material handling systems reduce human risk. They also increase operational consistency. Robotics are being deployed for inspection and maintenance in dangerous areas.

- Data Analytics and AI: Advanced sensors on equipment generate vast amounts of data. Artificial intelligence (AI) and machine learning analyze this data. They optimize processes in real-time. This includes predictive maintenance, optimizing crusher settings, and fine-tuning recovery circuits. For example, ZONEDING’s equipment uses Siemens PLC control cabinets and sensors. This makes its machines ready for intelligent operations and data integration.

- Improved Grinding Technologies: New grinding mills, like High Pressure Grinding Rolls (HPGRs) and stirred mills, offer energy savings. They create finer particles more efficiently than traditional ball mills. This improves gold liberation.

- Sustainable and Eco-Friendly Extraction: There is a strong global shift toward greener alternatives. Researchers are developing non-cyanide leaching reagents. These reagents offer environmental benefits. Dry stacking of tailings and water recycling are also becoming standard practices.

- Enhanced Ore Sorting: Technologies like X-ray transmission (XRT) or laser sorting allow miners to separate waste rock from valuable ore before fine grinding. This reduces the amount of material that goes through energy-intensive processing. It significantly lowers operational costs.

How Can ZONEDING Support Your Gold Mining Operations?

At ZONEDING, the complexities of gold mining are understood. The company designs and manufactures robust equipment. It supports various stages of a mineral processing plant. ZONEDING aims to enhance your efficiency and gold recovery.

Here is how ZONEDING helps:

- Comprehensive Equipment Range: ZONEDING offers a full spectrum of equipment. This ranges from primary crushers for initial size reduction to advanced grinding mills for fine liberation. Its product line also includes various mixers and conveyor systems essential for material handling throughout your plant. This allows for a one-stop solution. This reduces your hassle of coordinating multiple suppliers.

- Customization Capabilities: Every gold ore deposit is unique. ZONEDING understands this well. The company can customize equipment and production line solutions. ZONEDING considers your specific ore type, your required output, and your exact site conditions. ZONEDING’s specialized mineral processing engineers work closely with you. They design a system that fits your needs perfectly.

- Quality and Durability: ZONEDING uses high-wear-resistant steel in critical components. It sources parts from reputable international brands like Taiwan KELIJIA for hydraulics and German Schneider for variable frequency drives. This commitment to quality means ZONEDING’s equipment can withstand the harsh demands of continuous mining operations, leading to less downtime and lower maintenance costs.

- Full-Service Support: The company’s relationship with clients does not end with a sale. ZONEDING provides full-service support. This covers everything from detailed scheme design to equipment manufacturing, installation and debugging, staff training, and comprehensive after-sales maintenance. This ensures your operations run smoothly and efficiently from day one.

- Global Experience: ZONEDING has successfully exported its products to over 120 countries. This global experience gives ZONEDING a deeper understanding of diverse mining environments and regulatory requirements.This helps you achieve success.

FAQ

- Question 1: What is ‘refractory’ gold ore?

- Refractory gold ore means gold is locked within sulfide minerals or is very fine. It cannot be recovered easily using simple cyanidation. It needs pre-treatment first.

- Question 2: Why is crushing important for gold ore?

- Crushing breaks down large ore chunks. It reduces them to smaller, manageable sizes. This prepares the ore for grinding. It helps liberate the gold particles from the surrounding rock.

- Question 3: Can you recover gold without using cyanide?

- Yes, you can. Gravity separation methods are effective for coarser free gold. Flotation can concentrate gold-bearing sulfides. Newer non-cyanide leaching reagents are also under development and in use.

- Question 4: What are the main environmental concerns in gold mining?

- Major concerns include water consumption, tailings management (especially cyanide-contaminated tailings), land disturbance, and potential for acid mine drainage from sulfide ores. Modern mines focus on mitigation.

- Question 5: How does ZONEDING support gold miners with customization?

- ZONEDING offers tailored solutions. The company customizes equipment and full processing lines. This is based on your specific ore type, desired output, and operational conditions. ZONEDING’s engineers work with you to design the best system.

Conclusion

Understanding the types of gold ore is the foundation of efficient mining. Whether it’s a hard rock primary deposit or a loose secondary placer, the ore type dictates everything. It guides mining strategies, influences extraction processes, and determines final gold recovery rates. This article has explored how different geological formations demand specific approaches. From deep underground mining to surface-level gravity separation, the right method is key.

Contact ZONEDING today to discuss your specific gold ore processing needs and get a tailored solution.