全站搜索

Search the entire website

Search the entire website

High moisture content in your final sand or mineral product is a hidden profit killer. It means you’re paying to transport water, your material may not meet quality specifications, and it can be difficult to handle and stockpile. A high-efficiency dewatering screen is the solution, but choosing the right one is more than just picking a size. It’s a technical decision that directly impacts your operational efficiency and bottom line.

So, how do you select a dewatering screen that works perfectly for your specific application? As manufacturers who have designed and deployed these machines in over 120 countries, we’ve learned it comes down to five critical factors. This guide will walk you through each one with the depth you need, helping you make an informed decision that boosts your product quality and profitability.

Think of a dewatering screen as a specialized, high-tech colander for your industrial materials. Its primary job is not to separate particles by size (like a standard vibrating screen) but to efficiently remove water from a slurry of sand, aggregates, or mineral fines. It transforms a wet, soupy mixture into a damp, stackable, and transportable product, ready for sale or the next process stage.

It achieves this through a powerful combination of engineering principles. Two high-frequency vibratory motors create an intense, linear motion. This force, typically exceeding 5 Gs, combined with the screen deck’s slight uphill angle (around 5 degrees), works to:

The result is a final product with a dramatically lower moisture content, often as low as 12-15%, which is immediately ready for conveying and stockpiling without dripping.

You need a dewatering screen whenever excess water is costing you money, compromising your product quality, or creating handling headaches. It’s a critical component in many modern processing plants. At ZONEDING, we see them as essential in three main scenarios.

This is the most common application. A wheel sand washer or a spiral classifier produces a clean product, but the sand slurry it discharges can have a moisture content of 25% or more. This material cannot be sold—it’s too wet to meet standards like ASTM C33 for concrete sand, and it will create a messy, unstable stockpile. Placing a dewatering screen directly after the washer is the most efficient way to produce a drip-free, “free-draining” final product that can be immediately conveyed and sold.

In mineral processing and large-scale sand operations, managing tailings (fine waste material) is a major environmental and financial challenge. A dewatering screen is a highly effective tool for this task, transforming a slurry into manageable solids. This achieves two critical goals:

If your process requires thermally drying your material in a rotary dryer, a dewatering screen is a non-negotiable investment. Mechanically removing water with a dewatering screen uses a tiny fraction of the energy compared to evaporating it with heat. For example, removing one ton of water with a dewatering screen might cost a few dollars in electricity. Evaporating that same ton of water in a rotary dryer can cost ten to twenty times more in fuel. By dewatering the material first, you massively reduce the load on your dryer, cutting fuel bills and increasing overall plant throughput.

This is the most fundamental question, but it’s deeper than just “how many tons per hour?” You must consider the dewatering screen’s capacity in the context of your entire production line. A screen that is too small creates a bottleneck, causing material to back up at your sand washer and slowing down your whole operation. A screen that is oversized is an unnecessary capital expense, uses more energy than needed, and can run inefficiently.

You need to match the screen’s processing capacity to the output of the machine feeding it, which is often a sand washing machine or a hydrocyclone. At ZONEDING, our engineers don’t just sell you a screen; we analyze your entire process. We look at the solid tonnage and slurry volume from your classification system to recommend a screen that can handle your peak production volume without becoming a bottleneck. This ensures a smooth, continuous flow and maximizes the efficiency of your entire plant.

To get it right, you need to provide your equipment supplier with precise data:

| Feed Rate (Solids) | Recommended ZONEDING Screen Model | Typical Application | Why It Matters for You |

|---|---|---|---|

| 30-50 tph | TS1020 | Small sand washing plants | Avoids bottlenecks on smaller lines, ensuring your washer runs at full speed. |

| 80-120 tph | TS1530 | Medium aggregate production | A perfect match for standard spiral sand washers, maximizing throughput. |

| 150-200 tph | TS1836 or TS2040 | Large mining & quarry operations | Handles high volumes from multiple washers or large cyclones, preventing costly downtime. |

A screen is not a one-size-fits-all solution; it must be matched to the material it’s processing. The size, shape, and density of your material particles determine everything from the type of screen media to the required vibration force. Processing fine sand is completely different from dewatering coarse aggregates or mineral concentrates.

The Particle Size Distribution (PSD) is the most critical piece of data. This tells us the percentage of different-sized particles in your feed. At ZONEDING, we often ask for a material sample so our engineers can perform a sieve analysis. This allows us to specify the perfect screen panel configuration, ensuring you capture all your valuable product while efficiently removing water.

While sand is a common application, these screens are incredibly versatile.

The entire purpose of a dewatering screen is to get your product as dry as possible. Your target moisture content is a key performance indicator. For concrete sand, you might need to get below 15% to meet specifications. For mineral concentrates, every percentage point of water removed saves significant money on shipping.

The screen achieves this through a combination of high G-force vibration, an uphill inclination, and specialized screen panels. The powerful, linear G-force (often over 5 Gs) breaks the water’s surface tension. The uphill angle slows the material down, giving water more time to drain and compressing the material bed to squeeze out even more moisture. ZONEDING dewatering screens are engineered to maximize these actions, helping you achieve the lowest possible moisture content for your specific material, often as low as 12-15%.

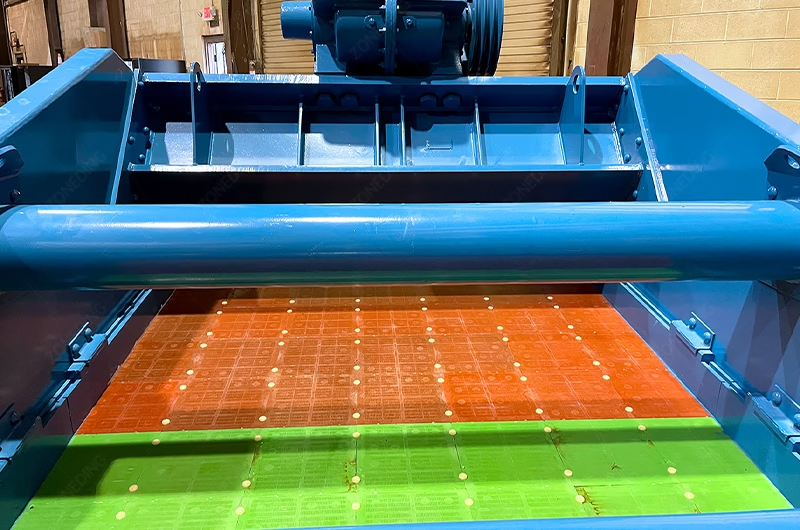

The screen deck is the heart of the machine, and the polyurethane panels are its most critical component. This is where the separation happens. Polyurethane is the industry-standard material due to its phenomenal resistance to abrasion and its flexibility, which reduces particle pegging and blinding.

However, the most important specification is the aperture size, or the size of the openings.

At ZONEDING, we use high-quality, mold-injected polyurethane panels for consistent aperture size and maximum wear life. We work directly with you to select the perfect aperture size based on your material’s particle size analysis. This direct customization is a key benefit of our factory-direct model.

A dewatering screen is a violent machine that shakes intensely for thousands of hours. If it isn’t built to withstand these forces, it will fail, leading to costly downtime. Structural integrity is not a feature you should compromise on, especially when importing equipment.

Key features to look for include:

To maximize the life of your investment, a simple maintenance routine is key.

1. What is the typical final moisture content I can expect?

For typical sand, a well-designed dewatering screen can reduce moisture from over 25% down to 12-18%. The final value depends on the particle size; finer material naturally retains more water.

2. How is a dewatering screen different from a regular vibrating screen?

A regular vibrating screen classifies materials by size and runs at a downward angle. A dewatering screen’s sole purpose is to remove water. It uses high-frequency, linear motion and an uphill angle to squeeze moisture out.

3. Can a dewatering screen handle materials with high clay content?

High clay content can be challenging as it can blind the screen. A pre-treatment step, such as a log washer to break up the clay, is often required before the material is sent to the dewatering screen.

4. How long do polyurethane screen panels last?

Service life depends entirely on the material’s abrasiveness and operating hours. In typical sand and gravel applications, high-quality panels can last from 6 to 18 months. We always recommend keeping a spare set on hand.

5. What information should I prepare before requesting a quote?

To get an accurate quote quickly, provide your supplier with: the required tons per hour, material type, particle size data (a PSD report is ideal), how the screen will be fed (pump or conveyor), your desired final moisture content, and your site’s voltage and frequency.

Choosing the right dewatering screen is a critical investment. By carefully evaluating these five factors, you can select a machine that will deliver real, measurable value to your operation.

As a factory-direct manufacturer with experience in over 120 countries, we offer a unique advantage. When you work with ZONEDING, you communicate directly with the engineers who will design your equipment. We provide complete customization based on your specific material and operational needs, from standalone machines to fully integrated, complete processing plants. Our robust construction, stress-relieved frames, and focus on system-wide efficiency ensure you receive a durable, high-performance machine that delivers a fast return on investment.

Ready to get your product dry and your profits up? Contact our engineering team today to discuss your dewatering needs.

A clear guide to the coal mining. Learn key stages: mining, preparation (cleaning), transportation, pulverization, and combustion for electricity generation.

View detailsDiscover 7 practical and effective methods to enhance gold recovery from ore, tailings, or waste materials, minimizing loss and maximizing yield.

View detailsLearn from 9 considerations about optimal equipment, material handling, safety protocols, and quality control to maximize efficiency in basalt processing plant.

View detailsLearn 9 core factors driving cone crusher prices. From brand and model to technical specs, materials, and after-sales support. Get precise budgeting Now!

View details