全站搜索

Search the entire website

Search the entire website

Do you want to boost your gold production? Maximizing gold recovery rates truly drives any mining operation. This holds true whether you process raw ore, tackle challenging tailings, or explore waste materials. Every lost gram of gold impacts your bottom line significantly. Knowing and applying the right techniques drastically increases your yield. This makes your operations more profitable and sustainable. This article guides you through 7 practical and effective methods. You can implement these to achieve better gold recovery. As ZONEDING, a leading manufacturer of mineral processing equipment, we understand efficient gold processing. We tailor our solutions to help you minimize loss and maximize your valuable returns.

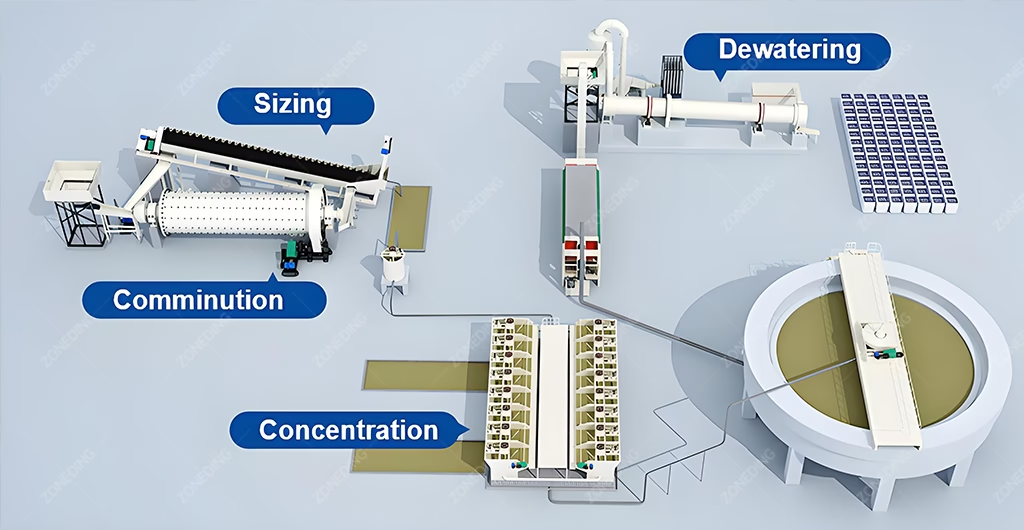

Optimizing your crushing and grinding process fundamentally improves gold recovery rates. It ensures gold particles sufficiently liberate themselves from the host rock. This makes them accessible for subsequent extraction methods. Without proper liberation, gold stays locked within waste material. This leads to significant losses.

Poor crushing and grinding can reduce gold recovery by 10-20%. This happens because larger gold particles might not get enough exposure to extraction reagents. ZONEDING’s jaw crushers and cone crushers specifically reduce ore efficiently. Our advanced ball mills then grind the material to optimal fineness. This exposes even the smallest gold particles. Precise size reduction, tailored to your specific gold ore mineralogy, drastically increases the surface area for chemical or physical separation. This setup ensures you avoid over-grinding, which wastes energy. You also avoid under-grinding, which leaves valuable gold trapped. Our equipment leads to higher gold recovery.

| Ore Type | Recommended Crushing | Recommended Grinding | Impact on Recovery |

|---|---|---|---|

| Hard Primary Ore | Jaw + Cone Crusher | Ball Mill (longer retention) | Maximizes liberation |

| Soft Oxidized Ore | Single Jaw Crusher | Rod Mill (shorter grind) | Prevents over-grinding |

| Complex Sulphide Ore | Jaw + Cone + Fine Crusher | Ball Mill (very fine) | Enables chemical access |

Gravity concentration stands as one of the oldest and most cost-effective methods for gold recovery. This is especially true for coarse, liberated gold. It works by separating gold from lighter gangue materials purely based on their density differences. This method often serves as a pre-concentrator ahead of more expensive techniques.

Installing gravity concentration equipment can capture up to 70% of coarse gold before it enters the main leaching circuit. This dramatically improves overall gold recovery. ZONEDING offers reliable shaking tables and spiral concentrators. We design these for efficient separation. These pieces of equipment prove highly effective for materials ranging from coarse to fine gold. Using gravity concentration can significantly reduce the amount of material needing subsequent chemical treatment. This lowers operating costs and reduces environmental impact. It forms a crucial step in many gold processing flowsheets. For instance, our spiral concentrators use the natural force of gravity, alongside water flow. They separate gold particles from lighter gangue. This provides an economical and environmentally friendly solution for early-stage gold recovery.

Froth flotation offers a highly effective method for gold recovery. This is especially true for fine gold, sulfidic gold ores, or gold associated with sulfide minerals. It works by selectively attaching gold particles (or gold-bearing sulfides) to air bubbles. These bubbles rise to the surface, forming a concentrate.

An optimized flotation circuit can achieve gold recovery rates of 85-95% for complex or refractory gold ores. ZONEDING’s flotation machines engineer superior air dispersion and pulp mixing. This maximizes the contact between gold particles and collectors, leading to higher recovery. Flotation performs particularly strongly for ores where gold disseminates finely within sulfide minerals, where other methods often struggle. We help you design a flotation circuit. It uses specific reagents, such as collectors, frothers, and modifiers. This enhances the selectivity of gold particles, ensuring minimal co-floating of gangue. This targeted approach proves crucial for high gold processing efficiency and lower downstream refining costs.

Cyanidation marks the most common chemical process for gold extraction globally. This is especially true for finely disseminated gold. It involves dissolving gold using a dilute cyanide solution. For optimal gold recovery rates, precise control over reagent dosage and process parameters proves essential.

When properly controlled, cyanidation can achieve gold recovery rates exceeding 90% for oxide gold ores. The process highly effectively leaches gold from its host minerals once liberated. ZONEDING provides robust leaching tanks and agitation equipment. We design them to facilitate efficient contact between the gold particles and the cyanide solution. Our engineers can assist you in designing a complete gold processing circuit. It includes carbon-in-pulp (CIP) or carbon-in-leach (CIL) systems for efficient gold adsorption onto activated carbon. Strict control of pH, dissolved oxygen, and cyanide concentration proves paramount. This maximizes gold extraction while minimizing cyanide consumption and environmental impact. Modern operations often integrate automated control systems. These ensure precise parameter management.

| Parameter | Impact on Gold Recovery | Control Measures |

|---|---|---|

| Cyanide Concentration | Too low: slow dissolution. Too high: reagent waste. | Automated dosing, real-time monitoring. |

| pH Level | Critical for safety + performance. Prevents HCN gas formation. | Lime or caustic soda addition, pH sensors. |

| Dissolved Oxygen | Essential for gold dissolution. Increases reaction kinetics. | Air sparging, oxygen injection, O2 sensors. |

| Particle Size | Finer particles dissolve faster. | Optimized grinding circuit. |

| Agitation | Ensures contact for efficient leaching. | High-quality agitators in tanks. |

Tailings dams and historic waste dumps often hold significant amounts of residual gold. This gold was often uneconomical or technically challenging for past technologies to recover. With advances in mineral processing equipment and increased gold prices, reprocessing these materials can become highly profitable. This offers new avenues for gold recovery.

Reprocessing historical tailings can add 5-20% to a mine’s total gold recovery over its lifetime, turning waste into profit. ZONEDING’s mobile crushing plants prove perfect for preparing tailings or waste dump material on-site. They efficiently reduce material size for further processing, minimizing transport costs. Our complete solutions often integrate fine grinding (like ball mills) with advanced flotation machines or specialized leaching circuits. This allows for the liberation and extraction of previously unrecovered gold. These systems handle variable feed characteristics and lower gold grades effectively. This makes the recovery of even small percentages economically viable. You convert environmental liabilities into economic assets.

Refractory gold ores present gold that does not readily recover by conventional cyanidation or gravity methods. This typically stems from its fine dissemination within sulfide minerals or its encapsulation in carbonaceous material. Tackling these ores requires specialized gold processing techniques to enhance gold recovery rates.

Implementing refractory gold ore processing can unlock up to 90% of gold from ores that yield less than 50% with traditional methods. ZONEDING provides advanced solutions for these challenging ores. This includes ultrafine grinding mills like jet mills or vertical mills to liberate encapsulated gold. We also support pre-treatment options such as:

These methods precede conventional cyanidation. Our equipment facilitates these intensive processes. Combining our robust mineral processing equipment with these advanced techniques allows you to recover gold from ores once considered uneconomical.

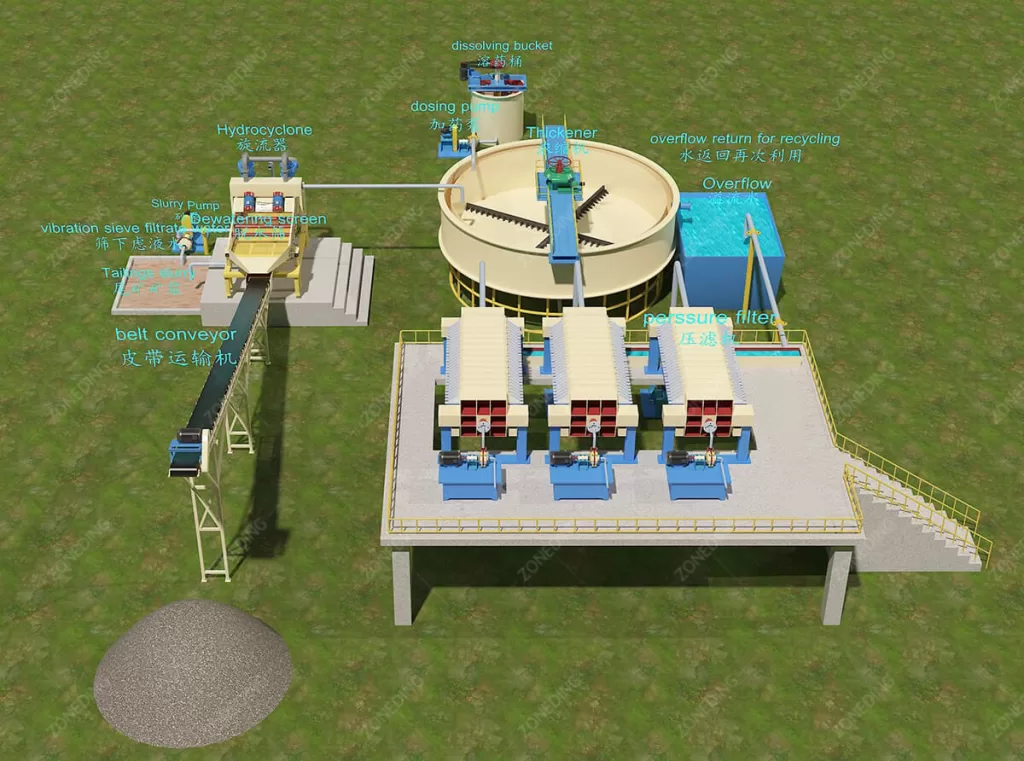

Efficient dewatering and responsible tailings management might not seem directly related to gold recovery rates. However, they significantly impact overall operational efficiency, cost, and environmental compliance. This indirectly affects profitability. Reducing water content in concentrates improves subsequent handling and refining efficiency.

Optimized dewatering can reduce moisture content in concentrates by 15-20%. This leads to lower transport and drying costs. It also aids overall gold processing efficiency. ZONEDING’s thickeners accelerate solid-liquid separation. Our filter presses produce a drier filter cake. This makes it easier and cheaper to transport and process further. For tailings, efficient dewatering reduces the footprint of tailings storage facilities (TSFs). It also allows for recovering and recycling process water, a critical resource. Dry stack tailings management, facilitated by highly efficient dewatering, minimizes environmental risks. It creates a safer, more stable waste product. This holistic view of gold processing not only contributes to better financial performance but also enhances your operation’s sustainability profile.

When you look to improve your gold recovery rates, your choice of mineral processing equipment supplier proves incredibly important. It determines the efficiency, reliability, and ultimate profitability of your entire operation. Here are the crucial factors you should consider to make an informed decision.

The field of gold recovery proves dynamic. Continuous innovation, decreasing ore grades, environmental concerns, and the need for increased efficiency drive it. Here are the latest trends you should know about in 2025 for gold processing.

Improving your gold recovery rates involves a continuous journey. It combines meticulous ore understanding with optimized mineral processing equipment and techniques. By focusing on smart crushing and grinding, effective gravity concentration, advanced flotation, precise cyanidation control, and exploring innovative approaches for tailings and refractory ores, you can significantly enhance your operational efficiency and profitability. You should not overlook the importance of efficient dewatering and sustainable tailings management. These indirectly contribute to your bottom line and environmental standing.

Partnering with an experienced mineral processing equipment manufacturer like ZONEDING provides you with more than just machines. You gain a comprehensive solution that considers every aspect of your gold processing needs. Our expertise helps you navigate the complexities, implement the latest technologies, and ultimately achieve higher gold recovery rates for enduring success.

Explore efficient stone crusher plant layouts. Learn how we configure feeder, jaw crusher, impact crusher, and vibrating screen for maximum aggregate output.

View detailsFollow limestone journey from raw material to finished product! This blog provides a detailed breakdown of each processing stage, from crushing to screening.

View detailsThink you know cone crusher liners? Our blog reveals surprising facts about selection, wear, and replacement that could save you time and money.

View detailsDive deep into complete Gold Ore CIP (Carbon-in-Pulp) Process Flow including crushing, grinding, leaching, adsorption, elution, electrowinning, and smelting.

View details