全站搜索

Search the entire website

Search the entire website

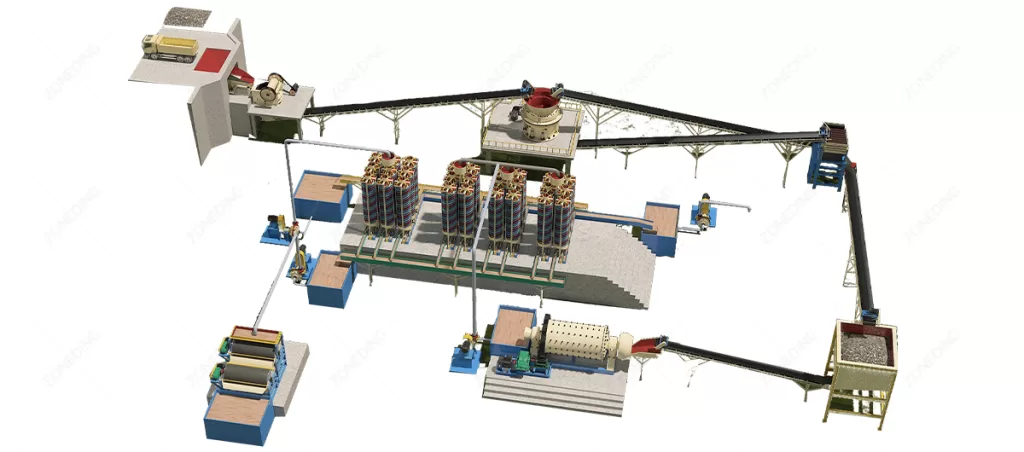

Gold captivates humanity for millennia. It symbolizes wealth and power. Extracting this metal involves complex processes. The Carbon-in-Pulp (CIP) method leads gold recovery. It offers efficiency and cost-effectiveness. This guide explores the entire Gold Ore CIP process flow. It details every step. Miners use it from initial crushing to the final gold bar.

Understanding the CIP process is vital for mining. It helps optimize gold recovery. It also ensures operational sustainability. This guide covers ore preparation. It explains chemical dissolution and final refining stages. It shows how each stage contributes to gold extraction success. CIP technology is a cornerstone in modern gold mining operations globally.

The Gold Ore Carbon-in-Pulp (CIP) process is a metallurgical technique. It recovers gold from ore. This technique uses leaching and adsorption. Its introduction revolutionized gold mining. This method effectively processes low-grade and refractory gold ores. It simplifies gold recovery. It combines leaching and adsorption into one circuit.

The CIP process provides high efficiency. It offers good economic returns. It enables miners to process ores previously uneconomical. This process minimizes capital expenditure. It also reduces operating costs. Its success depends on precise control. This includes material preparation and chemical handling.

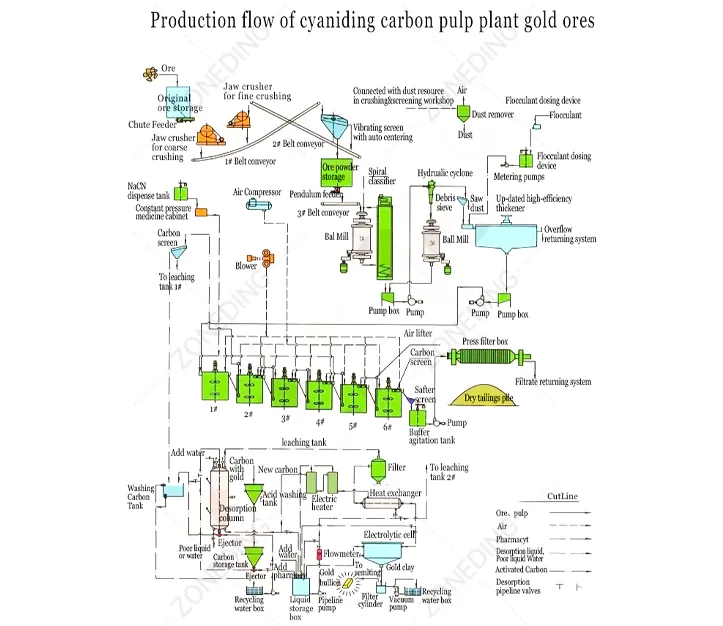

Cyanidation forms the CIP process core. It is a chemical method. It dissolves gold. Gold does not react with many chemicals. However, it reacts with cyanide ions. This forms a soluble gold-cyanide complex. The reaction occurs in an alkaline solution. Oxygen is also necessary for this reaction. Operators leach gold from the finely ground ore. This liquid phase is called a slurry.

The dissolution process relies on specific conditions. This includes pH control. It also requires sufficient oxygen supply. Mixing intensity in the tanks is important. ZONEDING provides specialized leaching tanks with strong agitators. These maintain optimal conditions. They ensure efficient gold dissolution. Proper control maximizes gold recovery.

CIP means Carbon-in-Pulp. CIL means Carbon-in-Leach. Both processes use activated carbon. Carbon absorbs gold from a cyanide-leached pulp. The main difference lies in the sequence. In CIP, leaching happens first. Gold adsorption onto carbon occurs after leaching.

In CIL, leaching and adsorption happen simultaneously. Both processes take place in the same tank series. This can reduce the overall plant footprint. CIL suits ores with faster leaching kinetics. CIP is better for slower leaching ores. It allows more leaching time before carbon goes in. ZONEDING designs and provides equipment for both CIP and CIL plants. This offers flexible solutions for specific ore characteristics.

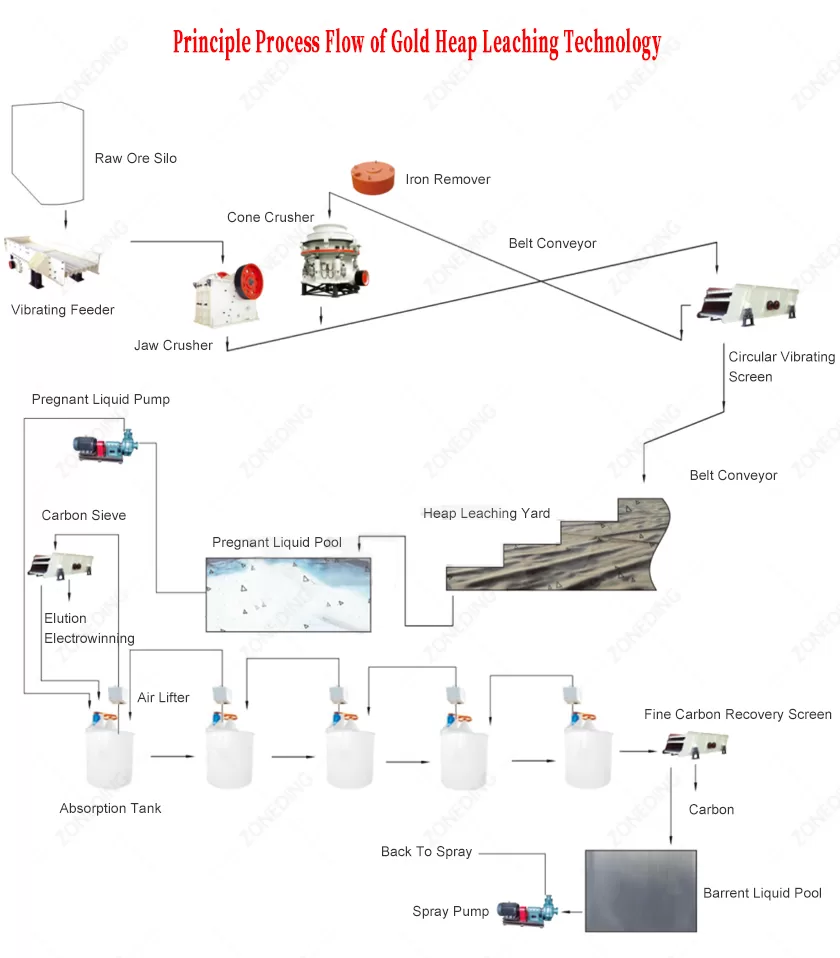

The first crucial step in gold recovery is comminution. This involves reducing ore size. Raw gold ore comes in large pieces from the mine. Gold particles are often microscopic. They hide within barren rock. Liberating these tiny gold particles requires significant size reduction. This allows chemicals to access gold during leaching.

Effective crushing and grinding directly impact recovery. They also affect downstream process efficiency. Poor comminution exposes gold poorly. This results in lower gold dissolution. It also increases chemical consumption. ZONEDING offers a full range of reliable equipment. This crushing and grinding equipment prepares ore for optimal gold extraction.

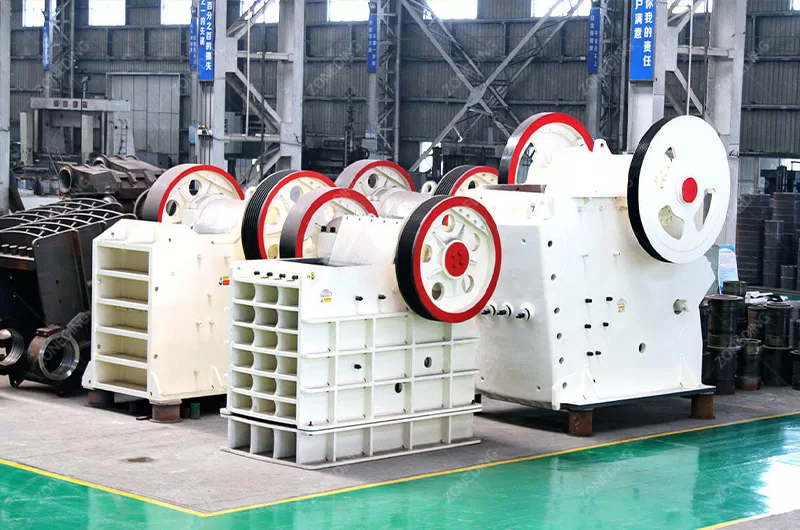

Raw ore typically feeds into a primary crusher. This machine reduces large rocks. Size usually becomes 100mm to 250mm. Jaw crushers are common for primary crushing. They handle hard, abrasive rocks very well. Their robust design ensures durability. It works in harsh mining environments. Primary crushing prepares material for further size reduction. It also protects subsequent equipment from oversized feed.

Primary crushing efficiency is critical. It impacts the entire plant capacity. ZONEDING’s jaw crushers feature high production. They also offer low power consumption. This makes them suitable for demanding gold mining. Proper equipment selection ensures future success.

After primary crushing, ore undergoes further size reduction. This involves secondary and tertiary crushing. Then follows fine grinding. Grinding aims to liberate gold particles. These particles often encapsulate within the host rock. Grinding reduces ore to a fine powder or slurry. This allows the cyanide solution to access the gold.

Ball mills and rod mills are common here. Ball mills use steel balls to grind ore. Rod mills use steel rods. The grinding circuit achieves specific particle size. This is often below 75 microns (200 mesh). Fine grinding ensures maximum gold exposure. ZONEDING optimizes grinding circuits. This reduces energy use. It also maximizes gold liberation for downstream processes.

Leaching is the chemical process. It dissolves gold from ground ore. This is a critical CIP stage. Cyanide solution mixes with the gold ore slurry. Agitation and aeration help this reaction. Gold forms a soluble complex. It then moves into the liquid phase.

Leaching efficiency directly impacts final gold recovery. Optimized leaching conditions are key. These include correct pH levels. Oxygen supply is vital. Contact time between cyanide and gold ore is important. ZONEDING provides advanced leaching equipment. This ensures consistent and effective gold dissolution.

Sodium cyanide (NaCN) is the main chemical for gold dissolution. It reacts with gold. Oxygen and water must be present. This forms gold-cyanide complex ions. The simplified reaction is the Elsner Equation. It requires a pH typically above 10. This prevents highly toxic hydrogen cyanide gas formation. Lime often goes into the slurry. It maintains alkalinity.

Understanding this chemistry is crucial for responsible operations. Strict reagent control ensures efficiency and safety. ZONEDING’s leaching circuits integrate precise dosing systems. These monitor and adjust chemical additions in real-time. This protects personnel and the environment. It also maximizes gold dissolution rates.

Leaching tanks are large vessels. They hold ore slurry and cyanide solution. Agitation is vital in these tanks. It keeps solid particles suspended. It also ensures good contact between gold, cyanide, and oxygen. Agitator mechanisms are inside the tanks. They provide continuous mixing.

Aeration is also necessary. Oxygen is consumed during gold dissolution. Operators sparge air or pure oxygen into the tanks. This maintains the required oxygen concentration. ZONEDING designs agitation leaching tanks. They have efficient agitators. These tanks also feature integrated aeration systems. This ensures homogeneous mixing and optimal oxygen levels. These factors are critical for high gold leaching rates.

Once gold dissolves, it needs recovery. Adsorption captures gold. It works from the pregnant (gold-bearing) solution. Activated carbon is the adsorbent. It highly attracts the gold-cyanide complex. This stage gives the process its name, “Carbon-in-Pulp.”

Adsorption efficiency depends on several factors. These include carbon quality. Carbon concentration also matters. Pulp density and contact time are crucial. Optimizing this stage is key. It ensures maximum gold loading onto carbon. This minimizes gold left in the tailings.

Activated carbon is a porous material. It has a very large surface area. This property makes it an excellent adsorbent. It selectively adsorbs the gold-cyanide complex from the slurry. This occurs even with base metal ions. Operators typically add granular carbon. It moves counter-current to slurry flow. The carbon then becomes “loaded” with gold.

Activated carbon quality directly impacts recovery. Its hardness and activity are important. ZONEDING’s CIP circuits optimize carbon usage. This minimizes carbon consumption. It also maximizes gold adsorption rates. This contributes to mining operation profitability.

The adsorption stage uses a series of CIP tanks. These tanks resemble leaching tanks. However, they retain carbon. Tanks are agitated to keep solids suspended. Activated carbon adds to the last tank. It moves to the first tank. The slurry flows the opposite way. Screens sit between tanks. They separate carbon from slurry.

This counter-current flow maximizes gold loading. Gold-rich slurry meets fresh carbon. Nearly barren slurry contacts gold-loaded carbon. Inter-stage screens are vital. They prevent carbon loss. ZONEDING provides high-quality inter-stage carbon screens. These ensure efficient carbon recovery within the CIP circuit.

After activated carbon loads gold, gold must recover. This process is called elution. Elution reverses adsorption. Operators then regenerate the carbon for reuse. This makes the CIP process circular and sustainable.

Efficient elution ensures high gold recovery. Effective carbon regeneration reduces operating costs. Both stages are crucial for economic gold production. ZONEDING offers advanced elution and regeneration systems. These systems optimize recovery and reuse.

Elution strips gold from loaded carbon. This typically uses a hot, high-pressure, caustic cyanide solution. The solution flows through a column. This column packs with loaded carbon. High temperature and chemicals desorb the gold-cyanide complex. It moves from carbon to solution. This creates a concentrated gold-bearing solution. Operators call this solution the “pregnant eluate.”

Various elution methods exist. These include the AARL process and pressure elution. Selection depends on factors like carbon loading and throughput. ZONEDING’s elution columns engineer for high efficiency. They ensure quick and complete gold desorption. This minimizes cycle times and maximizes recovery.

After elution, gold strips from carbon. However, it still contains organic foulants and fine minerals. These impurities reduce carbon activity. Regenerating carbon restores its adsorptive properties. Regenerated carbon then reuses in the CIP circuit. This significantly reduces fresh carbon consumption. It also lowers operational costs.

Regeneration typically involves acid washing. Thermal reactivation follows. Acid washing removes inorganic scale. Thermal reactivation heats carbon in a kiln. This burns off organic foulants. ZONEDING supplies robust equipment for carbon regeneration. This includes acid wash tanks. It also includes regeneration kilns. These systems ensure long-term carbon effectiveness. They contribute to plant sustainability.

The elution process yields a concentrated gold-bearing solution. This solution is now ready for final recovery. Electrowinning and smelting are these steps. Electrowinning recovers gold from solution as a solid. Smelting refines this solid into a gold dore bar.

These stages culminate the entire CIP process. They transform the invisible gold-cyanide complex. It becomes a tangible, high-value product. Precision and safety are paramount here. ZONEDING provides necessary equipment for these critical operations.

Electrowinning is an electrochemical process. It recovers gold from the pregnant eluate. The gold-bearing solution flows through electrowinning cells. These cells hold anodes and cathodes. Electric current passes through the solution. The gold-cyanide complex reduces. Gold metal deposits onto the cathodes. Cathodes typically use steel wool.

Gold plating process is controlled. It ensures high purity gold deposits. After a specific period, gold-loaded cathodes remove. Gold then strips or rinses from cathodes. This produces a gold-rich sludge or precipitate. ZONEDING supplies efficient electrowinning cells. They design for maximum gold recovery from the eluate.

Smelting is the final step. It transforms gold sludge or precipitate into dore bars. Dore is a gold and silver alloy. It is 70-90% pure gold. Gold-rich material mixes with fluxes. Fluxes help remove impurities. This mixture then melts in furnaces. Temperatures are very high.

Molten gold and impurities separate. Heavier molten gold collects at the bottom. Lighter slag (impurities) floats on top. Molten gold then pours into molds. This forms dore bars. These bars ship to a refinery for further purification. ZONEDING offers reliable smelting furnaces. They complete the gold recovery process. This results in valuable gold dore products.

Building and operating a CIP gold recovery plant is complex. Success depends on careful planning. It also relies on continuous optimization. Several key factors impact plant performance. These include technical considerations. Equipment choices and environmental practices are also vital.

Addressing these factors proactively increases gold recovery. It also ensures lower operating costs. This results in more sustainable operations. It creates more profitable mining. ZONEDING offers extensive expertise. This applies to plant design and optimization. ZONEDING supports clients at every project stage.

Every gold ore body is unique. Its mineralogy, grade, and physical characteristics vary greatly. Understanding these properties is fundamental. It drives effective CIP flow sheet design. This understanding requires extensive metallurgical test work. Samples test in laboratories. This determines optimal crushing and grinding sizes. It also assesses leaching kinetics.

Comprehensive test work determines proper cyanide and lime dosages. It also evaluates activated carbon performance. ZONEDING works with clients to conduct or analyze test work results. This ensures the plant design perfectly matches the ore. This reduces risks. It maximizes gold recovery from the start.

Mining and processing equipment choice is critical. High-quality, reliable equipment minimizes downtime. It maximizes throughput. Each CIP stage requires specialized machinery. From crushers to electrowinning cells, performance matters. Equipment must withstand continuous operation. It also faces abrasive and corrosive environments.

ZONEDING manufactures robust and efficient equipment. Their product range covers the entire CIP process. This includes jaw crushers, ball mills, agitation tanks, and carbon screens. Choosing the right ZONEDING solution ensures operational efficiency. It provides long-term reliability and high gold recovery rates.

Gold processing uses cyanide. It requires strict environmental management. Cyanide is a toxic chemical. Responsible handling and disposal are paramount. Modern CIP plants incorporate various safety features. They also include environmental protection measures. These include secure tailing storage facilities. Cyanide destruction circuits prevent discharge.

Regulatory compliance is a major consideration. It protects the environment and local communities. ZONEDING designs CIP plants with environmental responsibility. Solutions adhere to international safety standards. They also meet environmental standards. This includes integrated cyanide detoxification systems. This ensures sustainable and responsible gold production.

The Gold Ore CIP process flow is a sophisticated metallurgical achievement. It transforms raw gold ore into a precious metal. It combines crushing, grinding, leaching, adsorption, elution, electrowinning, and smelting. Each stage plays a critical role. Each stage contributes to efficient gold recovery. This process ensures the economic viability of many gold mining projects.

Optimizing every step is crucial for success. This includes understanding ore characteristics. It also involves selecting the right equipment. Adhering to strict environmental standards is vital. The CIP process continues as a cornerstone of modern gold extraction. It provides a reliable pathway from mine to gold dore bar.

ZONEDING is a leading manufacturer of mineral processing equipment. The company specializes in complete plant solutions. ZONEDING provides robust and efficient machinery for every CIP stage.

Contact ZONEDING today to discuss your Gold Ore CIP project. Receive a customized plant design and quote from our expert team.

A complete diagnostic chart for hammer crusher. We break down 9 common fault symptoms, explain the root causes, and provide effective, field-tested solutions.

View detailsLearn Differences between impact crushers and cone crushers. Know their distinct benefits, limitations, and applications to make choice for aggregate Plant.

View detailsIf you need a stone crusher? If you need on-site aggregate, this guide is for you. Learn 5 key signs that a crusher is the right investment for your project.

View detailsLearn the list of the top 10 most precious metals. Understand their critical uses, market value, and the scientific reasons behind their exceptional scarcity.

View details