全站搜索

Search the entire website

Search the entire website

People often think of sand on beaches or in deserts. They might also know sand is the primary ingredient in glass. However, a specific type of sand is much more versatile. This is known as silica sand. This industrial mineral is a cornerstone of modern manufacturing. Its unique properties make it essential for countless products. We use these products every single day.

Silica sand’s value comes from its high purity. It also has specific physical characteristics. Nature does not provide these qualities in a ready-to-use form. The raw material requires precise processing. This processing must meet strict industry standards. This guide uncovers seven surprising applications of silica sand. It reveals why this mineral is a hidden hero. Its uses range from smartphones to golf courses. Understanding these uses highlights the importance of effective mineral processing.

Silica sand is not just ordinary sand. People also call it quartz sand or industrial sand. Its chemical name is silicon dioxide (SiO₂). Several key properties distinguish it from regular construction sand. These properties make it incredibly valuable for industry.

The most important properties of silica sand include:

Achieving these properties requires sophisticated processing. Raw sand deposits contain impurities. These include clay, iron, and heavy minerals. Companies use advanced equipment to clean and purify the sand. Spiral sand washers remove clay. Magnetic separators remove iron. ZONEDING manufactures this equipment to meet industrial specifications.

High-purity silica sand is a manufactured product. Nature does not provide it in a ready-to-use form. The journey from a raw deposit to a final product involves several critical steps. This multi-stage process is known as beneficiation. Each stage requires specialized mineral processing equipment to remove specific impurities and refine the sand’s properties. The result is a consistent, high-value industrial mineral.

The exact process depends on the raw deposit’s quality. However, most silica sand purification plants follow a similar sequence. The goal is to increase the silicon dioxide (SiO₂) content systematically. This is achieved by removing unwanted materials at each step.

The process begins at the raw sand deposit. First, miners must remove large, unwanted materials. This includes oversized rocks, roots, and other organic debris. A vibrating screen is the primary tool for this task. It uses vibration to pass sand-sized particles through a mesh. It simultaneously rejects larger material. This initial step is called sizing. It ensures a consistent feed size for the rest of the plant. It also protects downstream equipment from potential damage. The result is a raw feed free of oversized contaminants.

After screening, the sand is still very impure. It is often mixed with fine particles of clay, silt, and dust. These fine impurities coat the valuable quartz grains. A spiral sand washer is essential for this stage. Its rotating screw tumbles the sand and water mixture. This scrubbing action effectively liberates the clay particles from the sand surface. The wash water carries away the fine, unwanted material. For deposits with very stubborn clay, an attrition scrubber provides more intense, high-energy scrubbing. This produces a clean sand slurry, free of fine clays.

Washing removes clay, but other mineral impurities remain. Heavy minerals and iron oxides are common contaminants. These impurities reduce the sand’s final brightness and purity. Removing them requires more advanced techniques. High-intensity magnetic separators are used to remove iron-bearing particles. This step is crucial for making the ultra-clear sand needed for glass. Other methods like spiral classifiers can remove heavy minerals. They use density differences to separate heavier particles from the lighter quartz sand. This stage significantly increases the SiO₂ content.

The final processing steps involve removing water. After washing and separation, the purified sand exists as a slurry. First, a dewatering screen removes the bulk of the water. It uses high-frequency vibration to drain water while retaining the sand. This process can produce a product with moisture content as low as 15%. For applications requiring a completely dry product, a rotary dryer is used. It tumbles the sand in a stream of hot air. The final product is a consistent, high-purity silica sand. It is now ready for bagging, shipping, and industrial use.

Glassmaking is the most famous use for silica sand. However, its applications extend far beyond windows and bottles. The following seven examples show its incredible versatility. Each use depends on the sand’s specific, controlled properties.

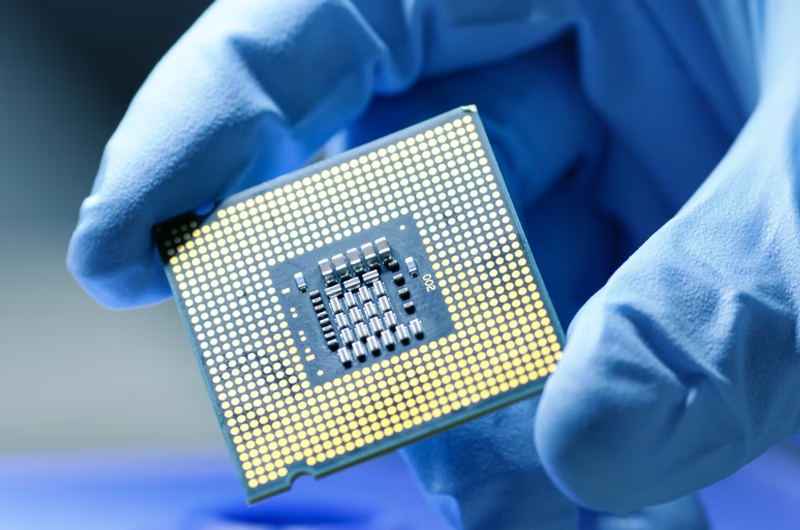

The heart of every electronic device is a semiconductor chip. These chips come from silicon wafers. High-purity silica sand is the raw material for these wafers. The process starts by heating silica sand with carbon. This creates metallurgical-grade silicon. Further chemical processes refine this silicon. The result is electronic-grade polysilicon. This material must be 99.9999% pure.

The extreme purity requirement is non-negotiable. Only the highest quality silica sand is suitable. The sand must be free of almost all contaminants. Any impurity can ruin a semiconductor’s electrical properties. This makes the purification and washing stages of sand processing critical. The entire electronics industry depends on this pure raw material.

Silica sand is a common functional filler in paints. It provides several key benefits to coatings. Its hardness improves the paint’s durability. This gives the paint better resistance to abrasion. This makes coatings last longer on high-traffic surfaces. The sand’s inert nature ensures it does not react with other chemicals. This property preserves the paint’s color and consistency.

Finely ground silica is sometimes called silica flour. It adds body and strength to the paint mixture. It can also create a textured finish for aesthetic appeal. This texture can also provide anti-slip properties. The uniform size of silica particles is important. They help maintain a smooth application and a consistent finish. Producers use equipment like Ball Mills to create the fine powder needed for these applications.

The pristine white sand in golf course bunkers is silica sand. Golf course designers choose silica sand for several reasons. Its angular grain shape helps the sand particles lock together. This prevents the golf ball from burying itself too deeply. The bright white color provides excellent visual contrast. It stands out against the green turf. This helps golfers see their ball easily.

Proper drainage is also crucial for course maintenance. The sand must have a uniform particle size. This uniformity allows water to pass through quickly. It keeps bunkers from becoming waterlogged after rain. Silica sand is also used for turf maintenance. “Top dressing” involves spreading a thin sand layer on greens. This action improves drainage and reduces soil compaction. It ultimately creates a smoother putting surface.

Silica sand is a natural and effective filter medium. People have used it for water purification for centuries. Modern water treatment plants use layers of sand. Precisely graded silica sand forms a filter bed. Water passes through this bed. The sand particles trap suspended solids, silt, and impurities.

The filter’s effectiveness depends on several sand properties. These include grain size, shape, and uniformity. Different layers in the filter use different sand grades. This allows them to remove particles of various sizes. Silica sand is chemically inert. This means it does not add unwanted substances to the water. It is a cost-effective and reliable method. It helps produce clean drinking water for communities worldwide.

The metal casting industry consumes large amounts of silica sand. Foundries use this sand to create molds and cores. The process involves mixing silica sand with a bonding agent. This mixture forms a mold for the metal part. Molten metal is then poured into this mold. The sand must perform under extreme conditions.

Silica sand is perfect for this task due to two key properties. Its high melting point allows it to withstand extreme temperatures. It does not break down when exposed to molten steel or iron. Its structural stability allows the mold to hold its shape. The metal cools and solidifies inside the mold. Workers then break away the sand mold. This action reveals the final metal part. The sand’s grain size affects the part’s surface finish.

Hydraulic fracturing is a technique to extract oil and gas. People often call it “fracking.” The process pumps high-pressure fluid into a well. This creates small fractures in shale rock. A “proppant” is added to the fluid to keep fractures open. This allows oil or gas to flow out.

High-purity silica sand is the most common proppant. It is often called “frac sand.” Frac sand must meet incredibly strict specifications. The grains must be very strong. They must withstand immense underground pressures without crushing. They also need a highly uniform, spherical shape. This shape allows for maximum flow of oil and gas. Only a few natural sand deposits can produce frac sand. These deposits require extensive processing to meet industry standards.

Silica sand is a key component in many building materials. Its use extends beyond simple concrete. It is a vital ingredient in mortar, stucco, and specialty cements. The sand acts as a structural filler. It provides both strength and bulk. In these applications, the sand’s purity and size affect the final product’s quality.

Silica sand is also used to produce certain concrete blocks. These are lightweight, precast building blocks. They are known for excellent thermal insulation. They also have great fire resistance. The manufacturing process involves mixing fine silica sand with cement and lime. The result is a strong yet lightweight material. This material is shaping modern, efficient construction practices.

Location: Vietnam

Challenge: A client wanted to produce high-purity silica sand. The sand was for the glass and electronics industries. Their raw sand deposit had high quartz content. However, it was contaminated with clay and iron oxides. These impurities made the sand unsuitable for high-value applications.

ZONEDING’s Solution: ZONEDING designed a complete washing and purification plant.

This custom-designed plant transformed the client’s raw material. It became a premium product that met strict specifications.

Silica sand is an essential industrial mineral. It is often overlooked by the public. Its value lies in a unique combination of properties. These include purity, hardness, and thermal stability. Glassmaking is a primary use. However, its role in high-tech electronics, paints, and sports shows its incredible range.

Each of these surprising applications demands specific sand properties. Grain size, shape, and purity must be precisely controlled. This reality highlights the critical role of mineral processing. Raw sand cannot become a high-value material without it. Effective screening, washing, and purification are necessary. The journey from deposit to product is a testament to sophisticated engineering.

ZONEDING provides engineered solutions for the mineral processing industry. The company delivers robust and efficient equipment. This equipment transforms raw materials into valuable industrial products.

Contact ZONEDING today to discuss your silica sand processing needs. Receive a customized quote from our engineering team.

Understand how the different types of gold ore influence gold mining strategies, extraction processes, and overall recovery rates for better decision-making.

View detailsThis guide details Aluminum essential roles, from everyday products like soda cans to critical industrial uses in aerospace, automotive, and construction.

View detailsExplore placer gold processing methods, from traditional gravity concentration to separation technologies. Learn to optimize mineral processing machines setup.

View detailsThis guide details gravity separation equipment, high-recovery techniques, and strategies to maximize alluvial gold processing. .

View details