全站搜索

Search the entire website

Search the entire website

Modern society relies on mined materials. They form the steel in buildings and the copper in electronics. Mining is the foundational industry for this progress. However, mineral deposits vary greatly. Extraction methods must adapt to these differences. Selecting the right mining method is a critical decision. It directly impacts a project’s safety, profitability, and environment.

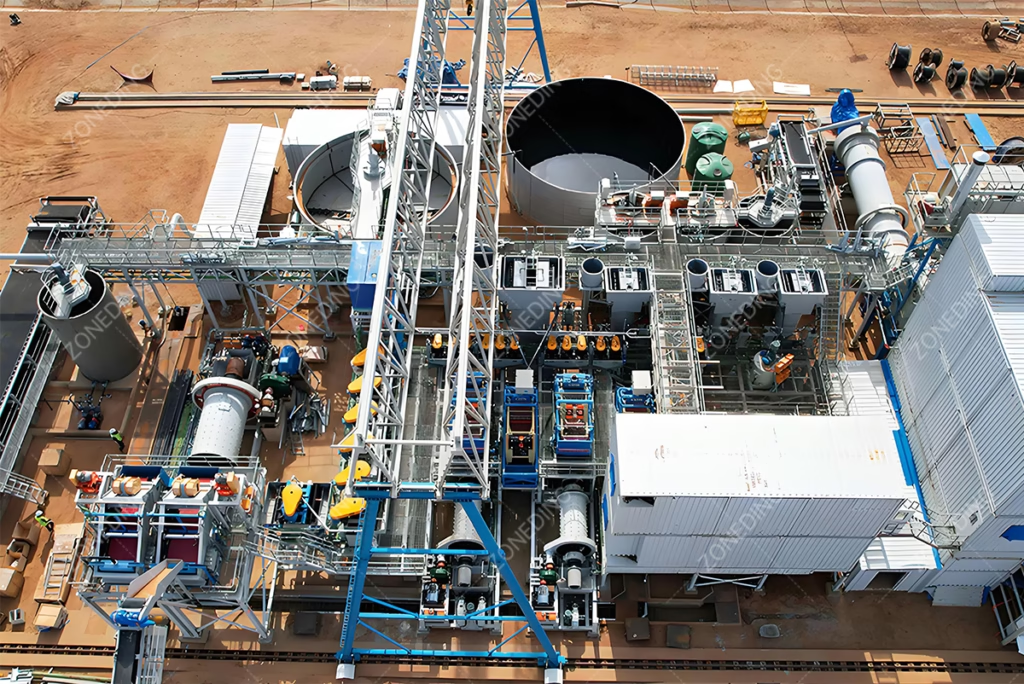

The two main categories are Surface Mining and Subsurface Mining. The choice depends entirely on the mineral deposit’s geology. After successful ore extraction, operations need reliable and efficient processing equipment. This guide provides a clear overview of both primary mining methods. It explains the start of this crucial industrial process. Understanding these methods helps in selecting the right downstream equipment, a specialty of manufacturers like ZONEDING.

Surface mining extracts minerals located near the Earth’s surface. The method involves removing the top layer of soil and rock. This layer is called overburden. Removing the overburden exposes the desired mineral deposit. Companies choose surface mining for large, shallow orebodies. These deposits are not suitable for tunneling.

This method is the most common form of mining globally. It accounts for most non-metallic minerals. It also produces much of the world’s coal and copper. The principle relies on scale and efficiency. Miners use massive machinery like draglines and haul trucks. They move enormous quantities of material. This makes the process highly productive and cost-effective. Ore from haul trucks is often the first material a Jaw Crusher processes at a plant.

Operators use several distinct methods of surface mining. They adapt their approach to the specific geology and mineral type. Each technique offers unique advantages for different deposits.

This is the most common method for near-surface metal deposits. Miners dig a large, open hole in the ground. The hole is often conical in shape. They create benches, or terraces, along the pit’s sides. Benches ensure stability and provide machinery access. Drilling and blasting break up the hard rock. Large shovels then load the ore onto haul trucks. These trucks transport the ore to the processing facility.

Best for: Copper, gold, iron ore, molybdenum.

Strip mining is primarily used for flat or gently dipping deposits. This includes coal seams or phosphate beds. The process removes overburden in long, narrow strips. A dragline deposits the overburden in the adjacent, completed strip. This continuous process allows for progressive land reclamation. The method is highly efficient for layered resources.

Best for: Coal, lignite, phosphate, oil sands.

This is a form of coal mining used in mountainous regions. It uses explosives to remove the top of a mountain. This action exposes underlying coal seams. Miners deposit the excess rock and soil in nearby valleys. These are known as “valley fills.” The method is efficient for coal extraction. However, it causes significant environmental changes.

Best for: Coal seams in mountainous terrain.

Quarrying is very similar to open-pit mining. The term typically applies to extracting building materials. This includes aggregates and dimension stone. In metal mining, the ore needs extensive processing. In quarrying, the extracted rock is often the final product. After blasting, operations crush and sort the material into various sizes. Complete crushing and screening plants are core technology for quarry operations.

Best for: Limestone, granite, marble, sand, gravel.

| Advantages of Surface Mining | Disadvantages of Surface Mining |

|---|---|

| Higher Safety: Poses fewer risks for workers compared to underground methods. It avoids dangers like tunnel collapses or gas issues. | Major Environmental Impact: Drastically alters the landscape. It requires extensive and costly land reclamation efforts. |

| Lower Cost: It is generally more economical. It allows the use of large, efficient machinery and bulk material handling. | Large Land Footprint: Requires a significant surface area. This space is for the pit, waste dumps, and infrastructure. |

| Higher Recovery Rate: Miners can extract nearly all of the ore. This leads to less waste of the valuable resource in the ground. | Pollution Concerns: Can generate significant dust and noise. It also has the potential for water contamination if not managed well. |

| Greater Production Capacity: Allows for a very high rate of extraction. The output in tons per day far exceeds most underground methods. | Weather Dependent: Operations can be stopped by heavy rain or snow. Extreme temperatures can also halt all activities. |

Subsurface mining is the method for deep mineral deposits. This is also known as underground mining. Miners create a network of tunnels and shafts. They do this instead of removing the overburden. These tunnels provide access to the orebody. The method is more targeted and has a smaller surface footprint. It is also more complex and expensive. Subsurface mining presents greater safety challenges.

The decision to mine underground is driven by depth. The stripping ratio is the ratio of overburden to ore. When this ratio is too high, surface methods become uneconomical. Subsurface mining requires a deep understanding of rock mechanics. This knowledge ensures tunnels remain stable. It relies on specialized equipment. This includes tools for drilling, hauling, and ventilation. The ore from these mines is often high-grade. It feeds into processing plants with robust equipment like Ball Mills for fine grinding.

Underground mining techniques are incredibly diverse. Engineers design them to match the orebody’s characteristics. These include the ore’s size, shape, depth, and stability.

This is one of the oldest and most common underground methods. Miners excavate a grid of “rooms” into the ore seam. They leave “pillars” of ore in a regular pattern. These pillars support the roof. This method is effective for flat, stable orebodies. The ore left in pillars can range from 30% to 50%. This fact affects the overall recovery rate of the mine.

Best for: Coal, salt, potash, limestone.

Longwall mining is a highly mechanized and productive method. Miners use it for extensive, flat seams like coal. They excavate a long wall of the seam in a single slice. A large machine with a rotating shearer cuts the mineral. The mineral then falls onto a conveyor belt. Hydraulic roof supports advance automatically. The roof behind the operation collapses in a controlled manner.

Best for: Flat, extensive coal seams.

Miners use this method for steeply dipping metal orebodies. They mine the ore in horizontal slices, or “cuts.” They backfill the excavated void after removing one slice. The fill material can be waste rock or cement. This fill provides a stable floor for the next slice. It also supports the surrounding rock walls. This is a selective and expensive method but allows high ore recovery.

Best for: Steeply dipping, high-grade gold or copper orebodies.

This is a large-scale, low-cost underground method. It is used for massive, low-grade deposits. Miners develop tunnels underneath the orebody. They drill and blast the base of the ore block. This undercutting causes the ore block to collapse under its own weight. The broken ore flows through funnels called “drawbells.” Loaders then pick it up and transport it to the surface.

Best for: Massive, low-grade deposits of copper or diamonds.

| Advantages of Subsurface Mining | Disadvantages of Subsurface Mining |

|---|---|

| Smaller Surface Footprint: Causes significantly less surface disturbance. It requires less land area than surface mining. | Higher Safety Risks: Workers face dangers like tunnel collapses and rock bursts. They also face risks from gas and hazardous dust. |

| Less Surface Waste: Produces much less waste rock at the surface. There is no large volume of overburden to manage. | Higher Cost: It is more expensive due to complex infrastructure. Ventilation, ground support, and slower production add cost. |

| Enables Access to Deep Ores: It is the only way to reach deep mineral deposits. Surface methods cannot access these valuable resources. | Lower Recovery Rate: Some methods leave ore behind. Room and pillar mining leaves significant ore for support pillars. |

| Not Dependent on Weather: Operations continue year-round. Surface weather conditions do not interrupt the workflow underground. | More Technically Complex: Requires specialized engineering skills. Experts in ventilation and rock mechanics are essential. |

The mining method only extracts the raw ore. This run-of-mine (ROM) material is not a final product. It is a mixture of valuable minerals and waste rock, called gangue. Mineral processing is the critical stage that follows extraction. It separates the valuable minerals from the gangue. This vital step turns low-value ore into a high-value concentrate.

The characteristics of the ore dictate the processing circuit design. These traits are heavily influenced by the mining method.

ZONEDING designs and manufactures the full range of this essential processing equipment. A successful mining operation depends on an efficient partnership. The extraction method must work seamlessly with the processing plant. A well-designed circuit minimizes energy consumption and maximizes mineral recovery.

The choice between surface and subsurface mining is necessary. It is a decision based on geology and economics, not preference. Each method has unique challenges, costs, and responsibilities. A successful operation depends on making the right choice.

Understanding these extraction methods provides crucial context. It helps to appreciate the entire mineral value chain. A commitment to providing robust and efficient processing equipment is essential. This equipment turns raw, mined rock into valuable materials that build our world.

ZONEDING provides engineered solutions that enhance mining profitability. The company delivers more than just machines.

Contact ZONEDING to discuss mineral processing needs. Get a quote for a solution tailored to your specific operation.

Choosing between used & new ball mill? This guide compares pros, cons, costs, performance, and maintenance of them, to help you select right grinding solution.

View detailsFrom artificial sand core definition to key advantages for construction, this guide covers everything you need to know about this increasingly aggregate.

View detailsExplore the typical price range of jaw crushers and understand the main factors influencing their cost, such as size, capacity, features, and machine quality.

View detailsUnderstand froth flotation (foam flotation) in mineral processing. Explore its core principles, key steps, and how it separates valuable minerals from ore.

View details