This guide explores Artificial Sand, also known as M-Sand or manufactured sand. Readers want to understand if this engineered aggregate is the right choice for construction needs. M-Sand offers superior quality and sustainability compared to natural river sand. ZONEDING specializes in providing the equipment and expertise to produce this high-quality material. The goal is to help achieve strong, durable, and cost-effective building solutions for your projects.

Table of Contents

What Exactly is Artificial Sand (M-Sand)?

Artificial Sand presents an precisely engineered fine aggregate material. Its production involves crushing hard quarries or other rock sources. Advanced machinery executes this special process. The resulting sand features controlled particle shapes and sizes. This contrasts with naturally formed river sand. People also call it M-Sand, which stands for “manufactured sand.” This name highlights its industrial origin.

Here is what you need to know about M-Sand:

- Engineered Aggregate: M-Sand is a fine aggregate material designed for construction. We create it by crushing hard rock. This process gives it very specific qualities.

- Controlled Particle Shape and Size: Unlike natural sand, M-Sand particles have angular, cubical shapes. We carefully control their size during manufacturing. This consistency helps in making strong concrete.

- High Purity: M-Sand production processes clean the material thoroughly. This means it has far fewer impurities like silt, clay, or organic matter. This purity is important for concrete quality.

- Reliable for Concrete: Because of its consistent shape, size, and purity, ZONEDING considers M-Sand a highly reliable Concrete Aggregate. It helps create predictable and high-performance concrete mixes.

- A Smart Solution: M-Sand provides a modern answer to the shortage of natural sand. It offers many benefits over traditional river sand. ZONEDING supplies robust equipment for producing this vital material.

What are the Differences Between Artificial Sand and Natural Sand?

Clear differences exist between Artificial Sand and natural sand. These distinctions significantly affect construction project performance. They also impact overall cost and environmental footprint. Understanding these differences helps users make informed choices.

Natural Sand

- Origin: Natural sand typically comes from riverbeds or seabeds. Natural processes create it.

- Particle Shape: Its particles usually appear rounded. Natural erosion by water causes this shape. Rounded particles can make concrete weaker.

- Impurities: Natural sand often contains impurities. These include silt, clay, and organic matter. These impurities can negatively affect concrete quality and setting.

- Particle Size: The particle size in natural sand also varies greatly. This variability can lead to inconsistent concrete mixes.

- Environmental Impact: Mining natural sand brings significant environmental costs. It can damage river ecosystems. It also depletes water tables.

- Availability: The availability of natural sand shrinks globally. This makes it more expensive and harder to find.

Artificial Sand (M-Sand)

- Origin: Mechanical crushing of hard rocks creates Manufactured Sand. It is an engineered product.

- Particle Shape: Its particles are angular and cubical. A controlled crushing process creates these shapes. These sharp angles lead to much better interlocking within concrete.

- Purity: M-Sand undergoes thorough washing and screening. This removes most impurities. This yields highly consistent, high-quality Sand Production.

- Particle Size: Production methods allow for controlled particle sizing. This gives users a uniform and consistent product.

- Environmental Benefit: Choosing M-Sand offers a more sustainable environmental option. It reduces reliance on natural sources. It provides a reliable and environmentally responsible sustainable aggregate.

- Cost-Effectiveness: M-Sand often serves as a cost-effective river sand alternative. You can produce it closer to construction sites.

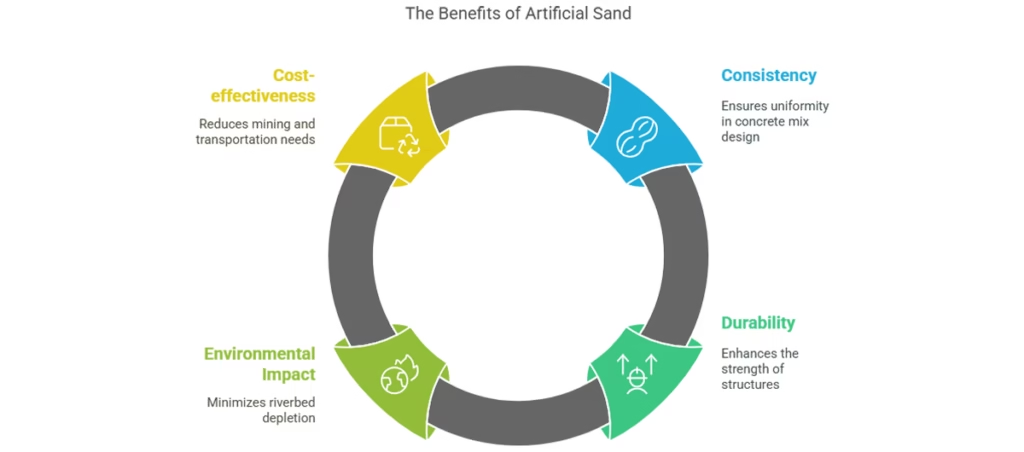

What are the Core Advantages of Artificial Sand As Building Material?

Artificial Sand offers many key benefits for construction work. These advantages position it as a superior choice for many diverse projects. Improvements in both quality and sustainability appear clear. These benefits lead to stronger, more reliable, and more environmentally friendly construction outcomes.

- Enhanced Strength and Durability: M-Sand particles feature an angular and rough texture. This unique shape helps them interlock much better within concrete mixes. They create stronger bonds between the aggregate and cement paste. Concrete will consequently achieve higher compressive strength. It will also exhibit better flexural strength. This directly translates to longer-lasting buildings and infrastructure built with M-Sand.

- Improved Workability: Manufactured Sand provides better workability for concrete. Its controlled particle shape and optimized size distribution reduce the amount of water and cement paste needed. This characteristic helps prevent issues like segregation and bleeding in fresh concrete.

- Reduced Impurities and Consistent Quality: Natural sand often contains harmful impurities. These include silt, clay, and organic matter. Such impurities can negatively affect concrete and its setting properties. M-Sand undergoes a controlled washing and screening process. This removes undesirable fine particles and contaminants.

- Environmental Sustainability: Choosing M-Sand proves a responsible environmental decision. Its production significantly reduces pressure on natural river sand resources. Excessive river sand mining damages river ecosystems, causes erosion, and disrupts natural habitats. M-Sand utilizes crushed rock from quarries. This minimizes the environmental impact of aggregate extraction. It helps preserve natural landscapes and ecosystems.

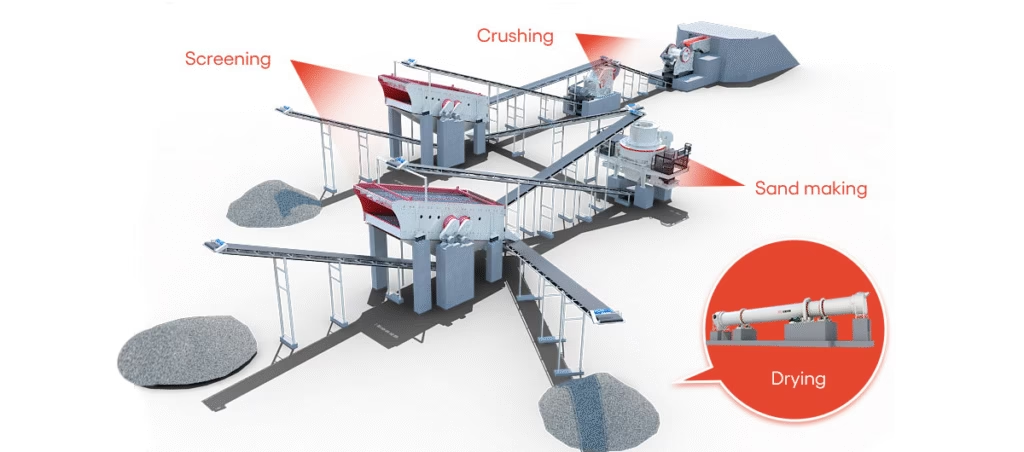

How to Make Artificial Sand? What is the Whole Process?

Manufacturing Artificial Sand involves a precise, multi-step industrial process. It starts with extracting large rocks and ends with fine, high-quality M-Sand. Complete production lines are designed and tailored for this purpose. The goal focuses on ensuring high efficiency and consistent product quality.

- Primary Crushing: The journey begins in the quarry. Large rocks, extracted from the quarry, enter a powerful jaw crusher. This machine effectively breaks down the massive rocks into smaller, more manageable pieces.

- Secondary Crushing: These smaller rocks then travel on conveyor belts to the next stage. Here, cone crushers or impact crushers further reduce the material’s size.

- Screening and Recirculation: After secondary crushing, vibrating screens separate the materials by size. Any oversized pieces automatically return for re-crushing. This ensures all material eventually reaches the desired size.

- Fine Crushing with VSI: The properly sized materials then proceed to the fine crushing stage. This stage proves crucial for producing high-quality Manufactured Sand. Operators often use a VSI crusher. The VSI crusher utilizes high-speed impact to break and shape the rocks, creating cubical and angular particles vital for excellent VSI crusher sand.

- Final Screening: The processed sand then passes through a final screening phase. This removes any remaining too-large or too-small particles to ensure uniformity.

- Washing (Optional but Recommended): Sometimes, a sand washing plant integrates into the line. This system washes away any remaining dust, silt, or clay. This ensures top-notch Sand Quality Control.

- Final Product: The final result is clean, consistent, and high-quality M-Sand. ZONEDING designs and installs full manufactured sand plant setups that perform highly efficiently and precisely for operations.

What are the Equipment in Artificial Sand Production Plant?

Designing an efficient Artificial Sand production plant demands specific, high-performance equipment. The right machinery ensures the entire process, from large rocks to fine sand, runs smoothly. At ZONEDING, a comprehensive range of robust equipment designed for reliability and optimal output is offered.

Key equipment typically found in a modern Manufactured Sand Plant includes:

- Jaw Crushers: These machines act as primary crushers. They take large rocks from the quarry and break them into smaller, manageable chunks. The jaw crushers feature strong, wear-resistant materials for long service life.

- Cone Crushers/Impact Crushers: These serve as secondary crushers. They further reduce the material’s size after primary crushing. Cone crushers excel with hard, abrasive materials, while impact crushers work well for softer rocks and generating good cubical shapes.

- VSI Crushers: The Vertical Shaft Impact (VSI) crusher proves vital for producing high-quality M-Sand. It uses high-speed impact to shape the particles. This creates the desirable cubical and angular grains crucial for concrete strength. VSI crusher sand machines are engineered for superior shaping.

- Vibrating Screens: These machines classify the crushed material by size. They ensure that only correctly sized particles move to the next stage. Screens also play a role in final product sizing and quality control.

- Sand Washing Machine (Optional): For projects requiring extremely clean sand, a sand washing machine is included. It removes excess fines, dust, and clay, improving the final product’s quality.

ZONEDING provides all these components. Specialized equipment like feeders, hoppers, and dust collection systems are also offered. The machines feature high wear-resistant steel and components from renowned international brands. This ensures robust performance. ZONEDING designs and supplies complete solutions, from individual machines to full turn-key manufactured sand plant setups.

How to Choose the Right Supplier for Your Project?

Choosing the right supplier for an Artificial Sand project marks a critical decision. The supplier largely determines the operation’s success, efficiency, and long-term profitability. Several key factors require consideration during the selection process to ensure a reliable and effective partnership.

- Supplier Experience and Reputation: A supplier with a proven track record in Sand Production offers invaluable expertise. Look for companies that have successfully designed and installed numerous Manufactured Sand Plant setups.

- Quality and Range of Equipment: A reputable supplier provides high-quality, durable machinery. This includes robust jaw crushers, efficient cone crushers, and advanced VSI crusher sand units. The equipment must tolerate high wear resistance. It needs to withstand the abrasive nature of hard rock. Ensure the supplier offers a comprehensive range of machines. This allows for a complete production line that can meet all needs.

- After-Sales Service and Support: This aspect proves vital for minimizing downtime and ensuring smooth operation. Look for a supplier that offers comprehensive services. This includes installation guidance, commissioning, operator training, and readily available spare parts. Excellent technical support helps quickly resolve any issues that arise.

- Pricing and Total Cost of Ownership: Compare pricing carefully. While cost is important, quality should never suffer compromise.

Why Choose ZONEDING

- ZONEDING, for instance, has been in the industry since 1990. We provide over 30 years of specialized experience. This extensive background signifies a deep understanding of crushing technologies and market needs. We also encourage you to check client testimonials and case studies.

- At ZONEDING, high-quality components receive prioritization. International brands like Siemens for PLC controls and Taiwan Kelly for hydraulic systems see usage. This ensures superior performance and longevity.

- ZONEDING provides full-service support. This extends from initial solution design and equipment manufacturing to installation, debugging, personnel training, and ongoing after-sales maintenance. Our products have exported to over 120 countries, demonstrating robust logistical and support capabilities globally.

- As a direct manufacturer, ZONEDING offers a significant price advantage. We eliminate middlemen, allowing for more competitive pricing. However, consider the total cost of ownership. This includes operational expenses, energy consumption, and maintenance costs. A cheaper machine that performs inefficiently or breaks down often will cost more in the long run.

ZONEDING actively integrates these cutting-edge trends into its designs and manufacturing processes. It continuously adopts intelligent controls, energy-efficient components, and flexible solutions. The aim is to provide the most advanced and competitive solutions available in the market today, helping businesses build for tomorrow.

What Latest Innovations Are Shaping the Future of Artificial Sand Production?

The Artificial Sand production industry continuously evolves. Staying informed about the latest innovations is crucial. These advancements shape the industry’s future. They offer significant improvements in efficiency, product quality, and sustainability.

- Increased Automation and Intelligence: Machinery becomes smarter. Operators will see more machines equipped with advanced Siemens PLC control cabinets and sophisticated sensors. These intelligent systems allow for remote monitoring, precise operational control, and predictive maintenance. This not only optimizes efficiency but also reduces human error, ensuring consistent Sand Quality Control throughout the process.

- Enhanced Energy Efficiency: A major innovation focus aims at reducing power consumption. New equipment designs and operational strategies target producing the same output with significantly less energy. This directly translates into lower operating costs. It also supports more sustainable production practices, which is crucial for the entire industry.

- Superior Particle Shaping Technology: VSI crushers continue to evolve. The goal involves producing an even greater percentage of perfectly cubical and angular particles. This further boosts Concrete Aggregate quality. It ensures M-Sand production leads to stronger and more durable concrete structures, meeting the highest engineering demands.

- Greater Focus on Sustainability and Waste Utilization: The industry moves towards more eco-friendly methods. This includes actively exploring and utilizing diverse raw materials. It involves processing quarry waste or construction and demolition debris into high-value Artificial Sand. Additionally, closed-loop water systems for sand washing become standard. This minimizes water consumption and environmental impact.

- Mobile Production Solutions: Mobile crushing and sand-making plants rapidly gain popularity. They offer unparalleled flexibility. These plants can easily move to different sites or adjust location within a large quarry. This greatly reduces transportation costs for raw materials or finished products.

FAQ

- Question 1: How Does Artificial Sand Impact the Strength and Durability of Concrete and Blocks?

- Artificial Sand directly enhances concrete and block strength. Its angular, cubical particles create superior interlocking when mixed. This results in tighter bonds and higher compressive strength. This leads to more durable and long-lasting structures.

- Question 2: Can Artificial Sand Truly Offer a More Cost-Effective Solution for Aggregates?

- Yes, it often does. While initial investment in a Manufactured Sand Plant exists, M-Sand eliminates reliance on increasingly scarce and expensive natural river sand. It also reduces transportation costs if produced closer to consumption sites.

- Question 3: What are the Environmental Benefits of Choosing Manufactured Sand?

- Choosing Manufactured Sand protects natural rivers and ecosystems from over-mining. It can also utilize quarry waste, reducing landfill. This makes M-Sand a sustainable and environmentally responsible choice for Building Aggregate needs.

Summary and Recommendations

Artificial Sand presents clear advantages. It brings superior strength, consistency, and environmental sustainability to construction projects. It forms a highly effective Concrete Aggregate solution. Experts firmly believe it represents the right choice for meeting modern building demands.

Careful project planning is recommended. Consider the specific type of sand required. Think about the required output capacity. Evaluate the significant long-term benefits that M-Sand offers. Choosing a reliable supplier proves crucial for success. Specific requirements should receive detailed discussion. At ZONEDING, expert advice and tailored solutions are always ready for provision. The goal is to help build stronger, more efficiently, and more sustainably.